Oblique cutting involves slicing materials at an angle to the surface, enhancing precision and reducing waste in manufacturing or woodworking processes. This technique improves the quality of cuts and can increase the efficiency of your operations by minimizing material distortion. Explore the rest of the article to uncover expert tips and detailed applications of oblique cutting.

Table of Comparison

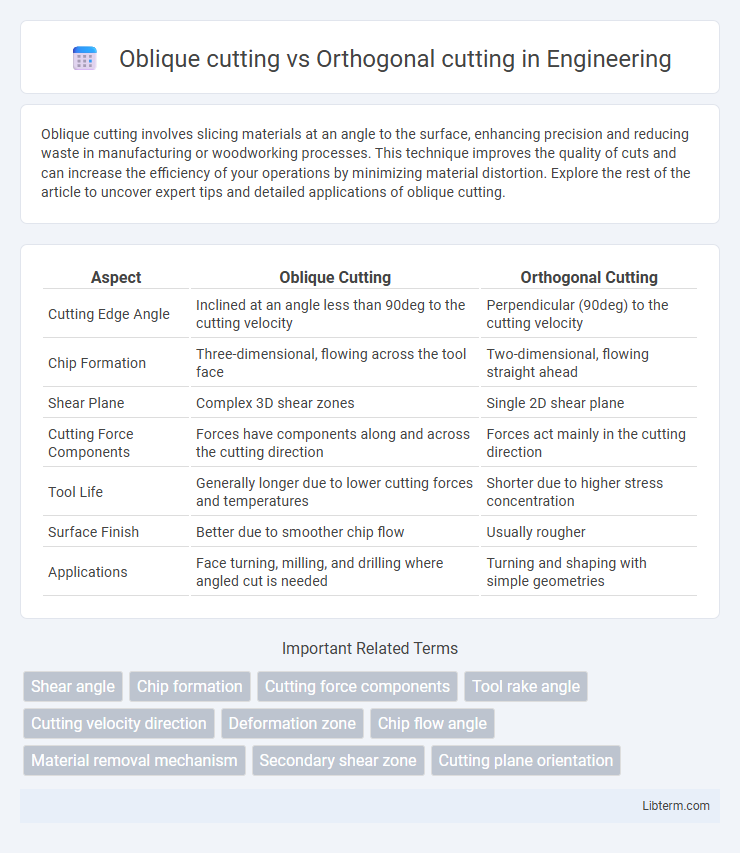

| Aspect | Oblique Cutting | Orthogonal Cutting |

|---|---|---|

| Cutting Edge Angle | Inclined at an angle less than 90deg to the cutting velocity | Perpendicular (90deg) to the cutting velocity |

| Chip Formation | Three-dimensional, flowing across the tool face | Two-dimensional, flowing straight ahead |

| Shear Plane | Complex 3D shear zones | Single 2D shear plane |

| Cutting Force Components | Forces have components along and across the cutting direction | Forces act mainly in the cutting direction |

| Tool Life | Generally longer due to lower cutting forces and temperatures | Shorter due to higher stress concentration |

| Surface Finish | Better due to smoother chip flow | Usually rougher |

| Applications | Face turning, milling, and drilling where angled cut is needed | Turning and shaping with simple geometries |

Introduction to Oblique and Orthogonal Cutting

Oblique cutting involves a cutting edge that intersects the workpiece at an angle other than 90 degrees, resulting in a combination of shear and compressive forces that enhance chip flow and surface finish. Orthogonal cutting features a cutting edge perpendicular to the workpiece surface, producing a straightforward shear plane that simplifies analysis of cutting forces and chip formation. These fundamental distinctions in cutting geometry influence tool life, machining efficiency, and chip morphology in manufacturing processes.

Defining Oblique Cutting

Oblique cutting is characterized by the cutting edge being inclined at an angle other than 90 degrees to the direction of tool travel, resulting in a chip flow that moves both in the cutting and axial direction. This cutting method reduces cutting forces and tool wear compared to orthogonal cutting, where the cutting edge is perpendicular to the cutting velocity vector. Oblique cutting enhances surface finish and tool life by distributing cutting stresses over a larger area of the tool edge.

Defining Orthogonal Cutting

Orthogonal cutting is a fundamental machining process where the cutting edge is perpendicular to the direction of tool travel, resulting in a two-dimensional cutting action. Unlike oblique cutting, which involves a three-dimensional material removal with the cutting edge at an angle to the cutting direction, orthogonal cutting simplifies the analysis of forces, chip formation, and heat generation. This process is essential for understanding basic cutting mechanics in metal cutting and tool design optimization.

Key Differences Between Oblique and Orthogonal Cutting

Oblique cutting involves a cutting edge angled relative to the cutting direction, causing the chip to flow at an angle, while orthogonal cutting features a cutting edge perpendicular to the cutting direction, producing a straight chip flow. Oblique cutting generally results in reduced cutting forces and improved tool life due to the distribution of cutting action over a larger edge, whereas orthogonal cutting typically exhibits higher cutting forces concentrated on a single edge. Surface finish quality tends to be better in oblique cutting because of smoother chip formation, contrasting with the rougher surface finish often observed in orthogonal cutting.

Cutting Mechanics and Force Analysis

Oblique cutting involves a cutting edge that is inclined at an angle to the direction of tool travel, producing a shearing action that results in a complex force system with three components: cutting force, thrust force, and radial force, whereas orthogonal cutting features a cutting edge perpendicular to the cutting direction, simplifying force analysis to mainly cutting and thrust forces. The shear plane angle in oblique cutting is generally larger, leading to more efficient chip formation and reduced cutting forces compared to orthogonal cutting, which experiences higher friction and forces due to direct material deformation. Force measurements in oblique cutting reveal a smaller magnitude of cutting force but an increased thrust force component influenced by the inclination angle, impacting tool wear and surface finish differently than in orthogonal cutting.

Tool Geometry in Oblique vs Orthogonal Cutting

Tool geometry in oblique cutting features a cutting edge inclined at an angle to the cutting velocity vector, resulting in a more complex tool-workpiece interaction with a three-dimensional shear zone. Orthogonal cutting employs a cutting edge perpendicular to the cutting direction, simplifying the chip formation into a two-dimensional shear plane. The rake and clearance angles in oblique cutting are designed to optimize shear deformation across multiple axes, while orthogonal cutting tool geometry focuses on minimizing cutting forces along a single plane for precise, controlled material removal.

Effect on Chip Formation

Oblique cutting produces a helical chip due to the angled cutting edge, resulting in reduced cutting forces and improved surface finish. Orthogonal cutting generates a straight, segmented chip as the cutting edge is perpendicular to the cutting velocity, leading to higher forces and more pronounced chip segmentation. The chip formation in oblique cutting also promotes better heat dissipation, enhancing tool life compared to orthogonal cutting.

Surface Finish and Tool Life Comparison

Oblique cutting generally produces a better surface finish than orthogonal cutting due to the shearing action and reduced cutting forces that minimize surface irregularities. The tool life in oblique cutting is typically longer because the load is distributed over a larger cutting edge, reducing wear and heat concentration. Conversely, orthogonal cutting experiences higher tool wear rates and rougher surface textures resulting from concentrated stresses and less efficient chip formation.

Industrial Applications of Oblique and Orthogonal Cutting

Oblique cutting is commonly used in turning operations where the cutting edge intersects the workpiece at an angle, optimizing chip flow and reducing cutting forces, which improves surface finish in complex geometries. Orthogonal cutting is favored in milling and shaping processes for its predictable shear plane and simplicity in analyzing forces, making it ideal for precision machining with straightforward chip removal. Industrial applications leverage oblique cutting for enhanced tool life and efficiency in high-speed machining, while orthogonal cutting excels in operations requiring controlled, consistent material removal such as in die manufacturing.

Summary: Choosing the Right Cutting Method

Oblique cutting involves a cutting edge angled to the workpiece, reducing cutting forces and improving surface finish, making it ideal for high-speed machining and complex geometries. Orthogonal cutting features a cutting edge perpendicular to the workpiece, providing simpler force analysis and is preferred for straightforward machining tasks with less tool wear. Selecting the right cutting method depends on workpiece material, desired surface quality, and machining efficiency requirements.

Oblique cutting Infographic

libterm.com

libterm.com