Six Sigma is a data-driven methodology aimed at improving business processes by reducing defects and minimizing variability. It employs statistical tools and techniques to enhance quality and operational efficiency in organizations. Discover how implementing Six Sigma can transform your processes and boost performance by reading the full article.

Table of Comparison

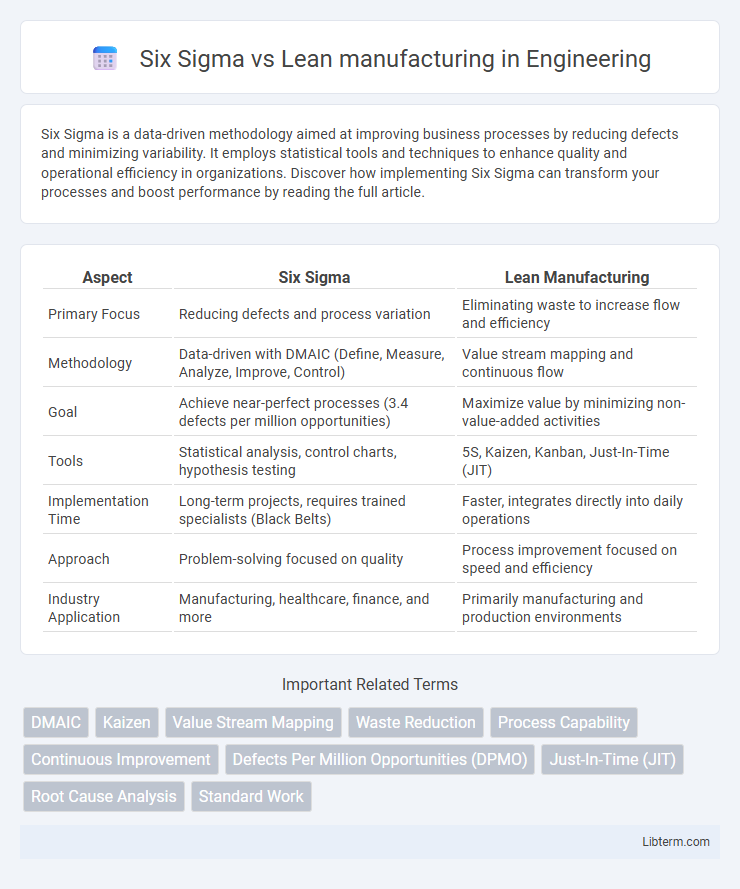

| Aspect | Six Sigma | Lean Manufacturing |

|---|---|---|

| Primary Focus | Reducing defects and process variation | Eliminating waste to increase flow and efficiency |

| Methodology | Data-driven with DMAIC (Define, Measure, Analyze, Improve, Control) | Value stream mapping and continuous flow |

| Goal | Achieve near-perfect processes (3.4 defects per million opportunities) | Maximize value by minimizing non-value-added activities |

| Tools | Statistical analysis, control charts, hypothesis testing | 5S, Kaizen, Kanban, Just-In-Time (JIT) |

| Implementation Time | Long-term projects, requires trained specialists (Black Belts) | Faster, integrates directly into daily operations |

| Approach | Problem-solving focused on quality | Process improvement focused on speed and efficiency |

| Industry Application | Manufacturing, healthcare, finance, and more | Primarily manufacturing and production environments |

Introduction to Six Sigma and Lean Manufacturing

Six Sigma is a data-driven methodology aimed at reducing defects and improving process quality by identifying and eliminating variability through statistical analysis. Lean Manufacturing focuses on maximizing value by eliminating waste and improving workflow efficiency across production processes. Both approaches complement each other by enhancing operational performance and driving continuous improvement in manufacturing environments.

Core Principles of Six Sigma

Six Sigma emphasizes reducing process variation and eliminating defects through a disciplined, data-driven approach guided by its DMAIC (Define, Measure, Analyze, Improve, Control) methodology. Lean manufacturing centers on waste elimination and improving flow to enhance efficiency, focusing on value stream mapping and continuous improvement. Core principles of Six Sigma include focusing on customer requirements, measuring defects in parts per million, and using statistical tools to drive decision-making and process improvement.

Fundamental Concepts of Lean Manufacturing

Lean manufacturing centers on eliminating waste through techniques such as value stream mapping and continuous flow to enhance operational efficiency. It emphasizes just-in-time production and respect for people to reduce inventory and improve quality. Fundamental concepts include identifying value from the customer perspective and streamlining processes to deliver maximum value with minimal resource consumption.

Methodologies: DMAIC vs Lean Tools

Six Sigma methodology primarily utilizes the DMAIC framework--Define, Measure, Analyze, Improve, Control--to systematically reduce defects and improve process quality through data-driven analysis and problem-solving. Lean manufacturing emphasizes a variety of tools such as Value Stream Mapping, 5S, Kaizen, and Just-In-Time production to eliminate waste, enhance flow, and increase operational efficiency. While DMAIC focuses on statistical control and variation reduction, Lean tools target process simplification and continuous improvement to streamline production cycles.

Key Differences Between Six Sigma and Lean

Six Sigma emphasizes reducing process variation and improving quality through data-driven statistical analysis, targeting defect reduction and consistency in production. Lean manufacturing focuses on eliminating waste and optimizing workflow to enhance overall process efficiency and speed. While Six Sigma uses DMAIC methodology for problem-solving, Lean applies continuous improvement principles like value stream mapping and just-in-time production to streamline operations.

Common Goals and Overlapping Strategies

Six Sigma and Lean manufacturing both aim to improve operational efficiency by reducing waste and minimizing defects, ultimately enhancing product quality and customer satisfaction. They share overlapping strategies such as data-driven decision-making, continuous process improvement, and employee involvement to streamline workflows and eliminate non-value-added activities. Organizations often integrate these methodologies to achieve faster cycle times, lower costs, and higher consistency in production.

Advantages and Limitations of Six Sigma

Six Sigma offers precise data-driven methods that significantly reduce process variation and defects, leading to improved product quality and customer satisfaction. Its structured DMAIC (Define, Measure, Analyze, Improve, Control) approach ensures systematic problem solving but requires extensive training and can be time-consuming to implement. Limitations include potential rigidity in fast-paced environments and challenges in adapting to creative problem-solving due to its heavy reliance on statistical analysis.

Pros and Cons of Lean Manufacturing

Lean manufacturing enhances operational efficiency by eliminating waste, reducing production time, and lowering costs, which leads to higher customer satisfaction and improved product quality. However, its implementation can be challenging due to the requirement for cultural change and continuous employee involvement, potentially causing resistance and initial productivity drops. Lean's focus on incremental improvements may also limit breakthroughs in process innovation compared to more data-driven methodologies like Six Sigma.

Choosing the Right Approach for Your Organization

Selecting between Six Sigma and Lean manufacturing depends on your organization's primary improvement goals and operational challenges. Six Sigma emphasizes reducing process variation and defects through data-driven methodologies, ideal for organizations seeking enhanced quality control and precision. Lean manufacturing focuses on eliminating waste and streamlining workflows, making it suitable for companies aiming to improve efficiency and reduce cycle times in production.

Integrating Six Sigma and Lean: The Lean Six Sigma Model

Integrating Six Sigma and Lean manufacturing combines the waste reduction focus of Lean with the defect reduction precision of Six Sigma to optimize overall operational efficiency. The Lean Six Sigma model leverages Lean's speed and flow improvements alongside Six Sigma's data-driven quality control methodologies, enabling organizations to streamline processes while maintaining high standards. This hybrid approach results in enhanced productivity, reduced costs, and improved customer satisfaction by systematically eliminating inefficiencies and minimizing variability.

Six Sigma Infographic

libterm.com

libterm.com