Vickers hardness measures a material's resistance to indentation using a diamond-shaped indenter under a specific load, providing precise evaluation for metals and ceramics. This testing method offers versatility by accommodating different materials and thicknesses, making it an essential tool in quality control and material science. Discover more about how Vickers hardness can impact Your material selection and engineering processes in the rest of this article.

Table of Comparison

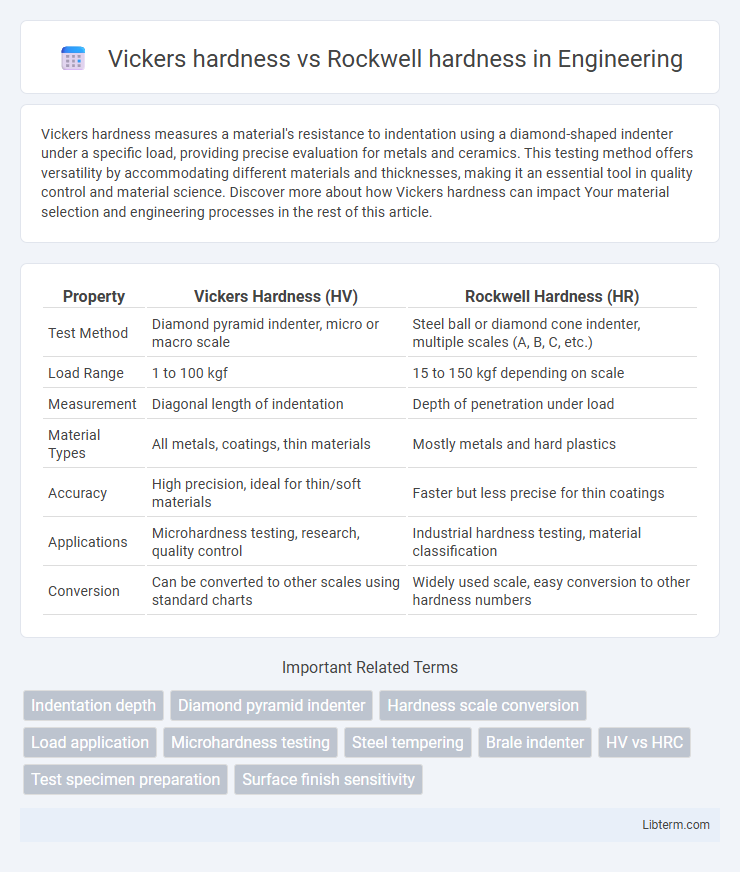

| Property | Vickers Hardness (HV) | Rockwell Hardness (HR) |

|---|---|---|

| Test Method | Diamond pyramid indenter, micro or macro scale | Steel ball or diamond cone indenter, multiple scales (A, B, C, etc.) |

| Load Range | 1 to 100 kgf | 15 to 150 kgf depending on scale |

| Measurement | Diagonal length of indentation | Depth of penetration under load |

| Material Types | All metals, coatings, thin materials | Mostly metals and hard plastics |

| Accuracy | High precision, ideal for thin/soft materials | Faster but less precise for thin coatings |

| Applications | Microhardness testing, research, quality control | Industrial hardness testing, material classification |

| Conversion | Can be converted to other scales using standard charts | Widely used scale, easy conversion to other hardness numbers |

Introduction to Hardness Testing

Hardness testing measures a material's resistance to deformation through indentation, with Vickers and Rockwell being two prevalent methods. Vickers hardness testing uses a diamond pyramid indenter to evaluate micro to macro hardness, providing precise measurements for thin materials and small parts. Rockwell hardness testing employs various steel or tungsten carbide indenters and measures depth of penetration, offering rapid assessment suited for bulk materials and quality control processes.

Overview of Vickers Hardness Test

The Vickers hardness test measures a material's hardness by pressing a diamond-shaped indenter into its surface under a specific load and calculating hardness based on the diagonal length of the indentation. This test offers high precision and is suitable for very thin materials and small parts due to its ability to use a broad range of test forces. Unlike the Rockwell hardness test, which uses different scales based on indenter type and load, the Vickers method standardizes hardness values by the indentation geometry, enabling consistent measurement across diverse materials.

Overview of Rockwell Hardness Test

The Rockwell hardness test measures material hardness by determining the depth of penetration of an indenter under a fixed load, offering rapid and straightforward results compared to the Vickers test, which uses a diamond pyramid-shaped indenter and calculates hardness by the size of the indentation. Rockwell hardness employs different scales (such as A, B, C) based on the indenter type and load, making it versatile for testing metals and alloys of varying hardness levels. This test is widely used in industrial quality control due to its speed, ease of use, and ability to provide direct hardness values without requiring optical measurement.

Principle Differences between Vickers and Rockwell Methods

The Vickers hardness test utilizes a diamond pyramid-shaped indenter to measure hardness by calculating the diagonal length of the indentation under a specific load, providing high precision for thin materials and coatings. In contrast, the Rockwell hardness test employs a steel or tungsten carbide ball or conical diamond indenter, measuring hardness based on the depth of penetration under a minor and major load, offering rapid and direct hardness values without the need for optical measurement. These principle differences in indentation measurement--diagonal length for Vickers versus depth of penetration for Rockwell--result in distinct applications, with Vickers suited for microhardness testing and Rockwell favored for routine industrial hardness testing of bulk materials.

Testing Procedures: Vickers vs Rockwell

The Vickers hardness test uses a diamond pyramid-shaped indenter pressed into the material with a specific load, measuring the diagonal length of the indentation to calculate hardness. Rockwell hardness testing involves pressing a steel or carbide ball or conical indenter into the material under a minor load followed by a major load, with hardness values derived directly from indentation depth. Both methods provide crucial hardness measurements, with Vickers preferred for thin materials and small parts, while Rockwell is favored for quick, non-destructive testing on bulkier samples.

Advantages and Limitations of Vickers Hardness

Vickers hardness testing offers the advantage of measuring very small and thin materials due to its ability to use a wide range of loads, providing precise hardness values for microstructures and thin coatings. It produces consistent and accurate results regardless of the test material's hardness, making it suitable for metals, ceramics, and composites. Limitations of Vickers hardness include the requirement for a polished, smooth surface and a longer testing time compared to Rockwell hardness, which uses simpler equipment and faster measurements.

Advantages and Limitations of Rockwell Hardness

Rockwell hardness testing offers rapid and direct hardness measurements without requiring extensive sample preparation, making it ideal for quality control in manufacturing processes. Its scale provides easy-to-read values and is suitable for a wide range of materials and thicknesses, especially metals and alloys. However, limitations include lower accuracy on very thin or heterogeneous materials and less sensitivity to small surface defects compared to Vickers hardness testing.

Applications: When to Use Vickers or Rockwell

Vickers hardness testing is ideal for measuring very thin materials, small parts, and coatings due to its ability to use a wide range of loads and produce precise microhardness values. Rockwell hardness testing is preferred for bulk materials and larger components in manufacturing settings because it provides rapid, direct hardness measurements with less sample preparation. Industries requiring detailed microstructural hardness profiles, such as aerospace and microelectronics, often use Vickers, while automotive and construction sectors commonly apply Rockwell testing for quality control.

Comparison Chart: Vickers vs Rockwell Hardness

Vickers hardness measures material resistance using a diamond pyramid indenter and is suitable for testing thin materials or small parts, providing precise hardness values typically ranging from 10 HV to 1000 HV. Rockwell hardness employs a steel or tungsten carbide ball or cone indenter with a depth measurement scale, offering rapid testing with scales like HRB for softer materials and HRC for harder metals, generally spanning values from 20 HRB up to 70 HRC. The comparison chart highlights Vickers for versatility and fine resolution across micro to macro hardness, while Rockwell excels in speed and simplicity for quality control in metals manufacturing.

Choosing the Appropriate Hardness Test

Choosing the appropriate hardness test depends on the material type and the precision required; Vickers hardness test offers high accuracy for thin materials and small parts due to its microscopic diamond indenter and can measure hardness across a wide range of hardness values. Rockwell hardness test provides faster, more convenient results with less surface preparation, making it suitable for bulk metals and larger samples where indentation depth can be reliably measured. Understanding the specific application and sample characteristics is essential to selecting between the detailed microhardness data from Vickers and the rapid, practical measurements from Rockwell hardness testing.

Vickers hardness Infographic

libterm.com

libterm.com