Rotameters measure fluid flow using a float that rises and falls within a tapered tube, providing a visual indication of flow rate, while electromagnetic flow meters use Faraday's law to measure the velocity of conductive liquids without moving parts. Both devices offer distinct advantages depending on the application, with rotameters known for simplicity and affordability, and electromagnetic flow meters praised for accuracy and suitability in dirty or corrosive fluids. Explore the article to understand which flow meter best suits your specific measurement needs.

Table of Comparison

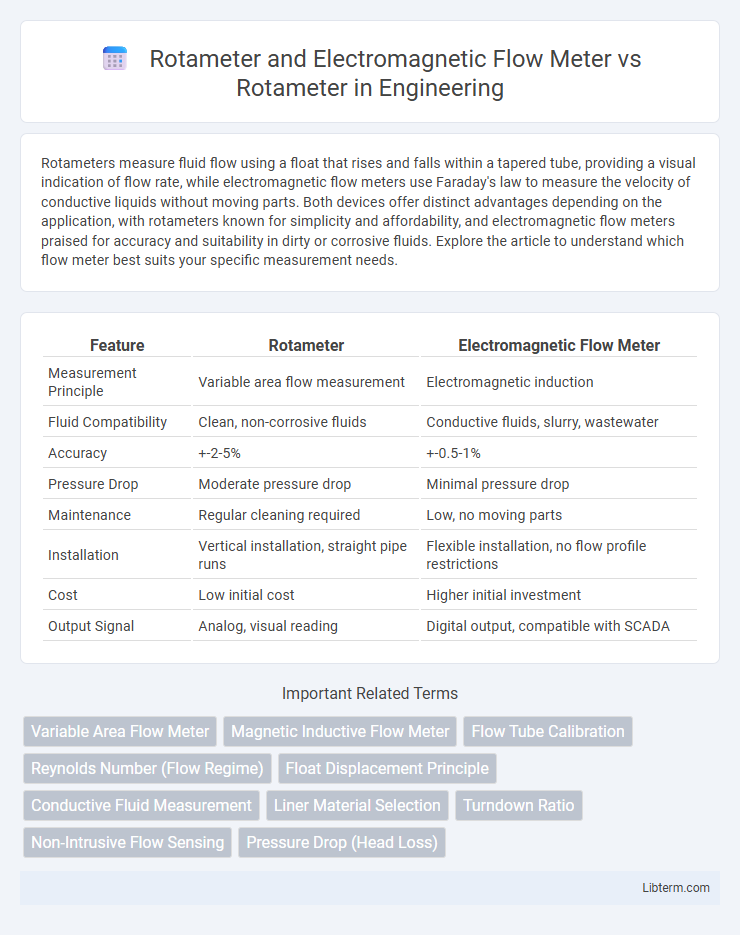

| Feature | Rotameter | Electromagnetic Flow Meter |

|---|---|---|

| Measurement Principle | Variable area flow measurement | Electromagnetic induction |

| Fluid Compatibility | Clean, non-corrosive fluids | Conductive fluids, slurry, wastewater |

| Accuracy | +-2-5% | +-0.5-1% |

| Pressure Drop | Moderate pressure drop | Minimal pressure drop |

| Maintenance | Regular cleaning required | Low, no moving parts |

| Installation | Vertical installation, straight pipe runs | Flexible installation, no flow profile restrictions |

| Cost | Low initial cost | Higher initial investment |

| Output Signal | Analog, visual reading | Digital output, compatible with SCADA |

Introduction to Flow Measurement Technologies

Flow measurement technologies such as rotameters and electromagnetic flow meters enable precise monitoring of fluid dynamics in industrial processes. Rotameters utilize a tapered tube and float to visually indicate flow rate, offering simplicity and cost-effectiveness for low-pressure applications. Electromagnetic flow meters employ Faraday's law to measure conductive fluid flow with high accuracy and no moving parts, making them ideal for wastewater treatment and chemical processing.

What is a Rotameter?

A Rotameter is a mechanical flow measurement device that uses a tapered tube and a float to indicate the flow rate of liquids or gases by varying the position of the float according to flow velocity. Unlike an Electromagnetic Flow Meter, which measures flow based on Faraday's law of electromagnetic induction and requires conductive fluids, the Rotameter operates purely on the principle of gravity and fluid dynamics, making it suitable for a broader range of fluid types, including non-conductive fluids. Rotameters provide a simple, cost-effective way to measure flow rates visually, but they are less accurate and more limited in scale compared to Electromagnetic Flow Meters, which offer precise, non-intrusive measurements ideal for industrial applications with conductive fluids.

How Rotameters Work: Principle of Operation

Rotameters operate on the principle of variable area flow measurement, where a float rises in a tapered tube in response to fluid flow, balancing gravitational and flow forces to indicate flow rate. The float's position correlates directly with the volumetric flow rate, allowing precise, mechanical readings without electrical power. Unlike electromagnetic flow meters that measure flow based on Faraday's law of electromagnetic induction suitable for conductive fluids, rotameters provide simple, cost-effective visual flow measurement ideal for clear liquids and gases.

Advantages and Limitations of Rotameters

Rotameters offer a simple, cost-effective solution for measuring flow rates in various industries, providing direct visual readings without the need for power or complex calibration. They are limited by their sensitivity to fluid viscosity, pressure, and temperature changes, reducing accuracy in turbulent or low-flow conditions. Unlike electromagnetic flow meters, rotameters are unsuitable for electrically conductive fluids and lack advanced digital output capabilities for process automation.

Overview of Electromagnetic Flow Meters

Electromagnetic flow meters measure fluid velocity by applying Faraday's law of electromagnetic induction, offering precise flow measurement for conductive liquids without moving parts, unlike rotameters that rely on a float rising in a tapered tube. These meters provide high accuracy, minimal pressure drop, and are unaffected by fluid viscosity or density changes, making them suitable for a wide range of industrial applications including water treatment and chemical processing. Rotameters are simple, cost-effective, and ideal for low flow rates, but electromagnetic flow meters excel in durability and measurement consistency for complex or corrosive fluids.

Working Principle of Electromagnetic Flow Meters

Electromagnetic flow meters operate based on Faraday's law of electromagnetic induction, measuring flow velocity by detecting voltage generated as a conductive fluid passes through a magnetic field. Unlike rotameters, which rely on mechanical float displacement to indicate flow rate, electromagnetic flow meters provide high accuracy with no moving parts, making them suitable for dirty or corrosive fluids. This working principle enables precise, maintenance-free flow measurement in water treatment, chemical processing, and slurry applications.

Rotameter vs Electromagnetic Flow Meter: Key Differences

Rotameters and electromagnetic flow meters differ primarily in measurement principles and applications; while rotameters use a variable area flow measurement technique relying on a float rising in a tapered tube, electromagnetic flow meters operate based on Faraday's law of electromagnetic induction, measuring flow velocity with no moving parts. Rotameters are ideal for low-cost, simple, and visual flow measurement in clean liquids and gases, whereas electromagnetic flow meters provide accurate readings for conductive fluids, handling high flow rates in industrial processes. Key differences include rotameters' mechanical operation and limited fluid compatibility versus electromagnetic flow meters' electronic measurement, superior precision, and suitability for corrosive or dirty fluids.

Application Scenarios: Where Each Meter Excels

Rotameters excel in low-pressure, clean fluid flow measurement with visibility requirements, commonly used in laboratory settings, water treatment, and chemical dosing due to their simplicity and direct reading capability. Electromagnetic flow meters outperform in measuring conductive liquids in harsh industrial environments such as wastewater treatment, pulp and paper, and slurry processes, providing high accuracy and no moving parts. While rotameters are best suited for small-scale, transparent fluid applications, electromagnetic meters dominate large-scale, electrically conductive fluid measurements with minimal maintenance needs.

Accuracy and Reliability Comparison

Rotameters provide reliable flow measurement for low-viscosity fluids but exhibit limited accuracy in turbulent or varying flow conditions due to their mechanical design. Electromagnetic flow meters deliver superior accuracy and consistent performance, especially with conductive liquids, by measuring flow velocity directly and eliminating moving parts susceptible to wear. In industrial applications requiring precise monitoring and high reliability, electromagnetic flow meters outperform rotameters by offering greater measurement stability and resistance to flow disturbances.

Choosing the Right Flow Meter for Your Needs

Selecting the right flow meter depends on factors like fluid type, accuracy requirements, and installation environment. A Rotameter offers simplicity and low cost for clean, low-viscosity fluids with moderate accuracy, while an Electromagnetic Flow Meter excels in handling conductive liquids with high accuracy and no pressure loss. Consider medium properties, measurement range, and maintenance needs when choosing between a Rotameter and an Electromagnetic Flow Meter for optimal performance and cost efficiency.

Rotameter and Electromagnetic Flow Meter Infographic

libterm.com

libterm.com