Shear panels play a critical role in enhancing structural stability by resisting lateral forces such as wind or seismic activity, preventing deformation or collapse. These panels are commonly used in framing systems for buildings and bridges to provide rigidity and distribute loads effectively. Discover how shear panels can secure Your construction projects and ensure long-term safety by reading the full article.

Table of Comparison

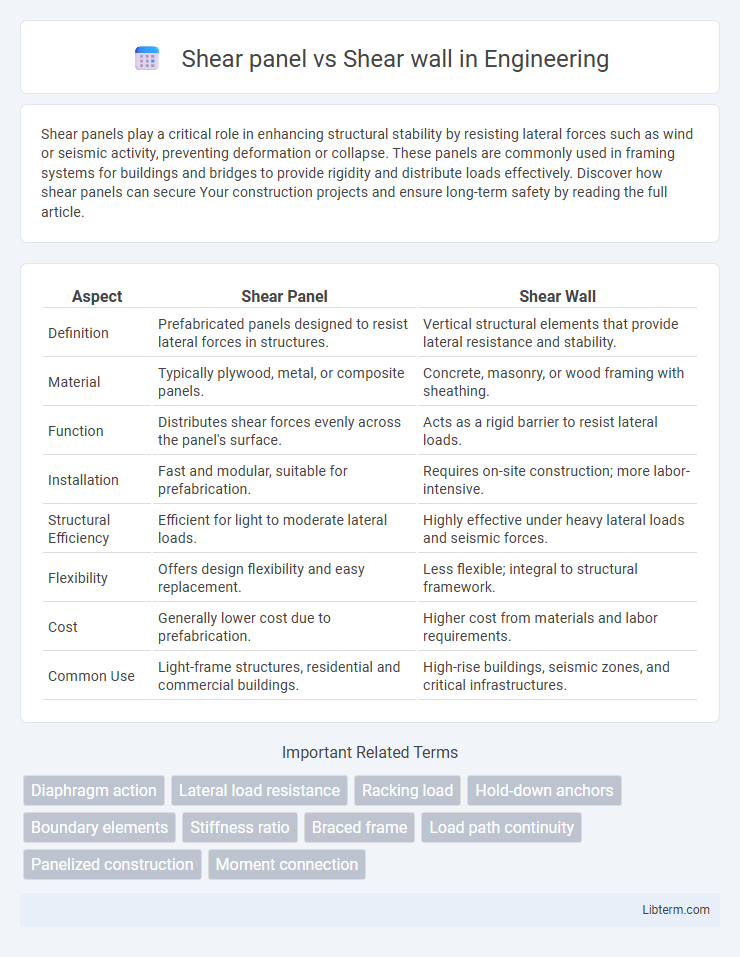

| Aspect | Shear Panel | Shear Wall |

|---|---|---|

| Definition | Prefabricated panels designed to resist lateral forces in structures. | Vertical structural elements that provide lateral resistance and stability. |

| Material | Typically plywood, metal, or composite panels. | Concrete, masonry, or wood framing with sheathing. |

| Function | Distributes shear forces evenly across the panel's surface. | Acts as a rigid barrier to resist lateral loads. |

| Installation | Fast and modular, suitable for prefabrication. | Requires on-site construction; more labor-intensive. |

| Structural Efficiency | Efficient for light to moderate lateral loads. | Highly effective under heavy lateral loads and seismic forces. |

| Flexibility | Offers design flexibility and easy replacement. | Less flexible; integral to structural framework. |

| Cost | Generally lower cost due to prefabrication. | Higher cost from materials and labor requirements. |

| Common Use | Light-frame structures, residential and commercial buildings. | High-rise buildings, seismic zones, and critical infrastructures. |

Introduction to Shear Panels and Shear Walls

Shear panels and shear walls are critical structural elements designed to resist lateral forces such as wind and seismic loads, ensuring building stability and safety. Shear panels typically consist of plywood or steel sheets fastened to framing members, providing flexibility and quick installation in various construction types. Shear walls are vertical, continuous elements made of reinforced concrete, masonry, or wood, offering greater stiffness and strength for high-performance lateral load resistance in multi-story buildings.

Defining Shear Panels

Shear panels are structural elements designed to resist lateral forces by transferring shear loads between floors or walls, often constructed from plywood or oriented strand board (OSB) attached to framing members. Unlike shear walls, which are full-height walls providing both lateral strength and vertical load support, shear panels function primarily as in-plane shear resistors within a framed structure. These panels enhance stability by preventing racking and are commonly used in lightweight wood or steel frame buildings to improve seismic and wind performance.

What is a Shear Wall?

A shear wall is a structural element designed to resist lateral forces such as wind and seismic loads by transferring these forces to the foundation, enhancing a building's stability. Constructed from reinforced concrete, masonry, or wood, shear walls provide significant rigidity and strength, preventing deformation and collapse during lateral stress. Unlike shear panels, which are prefabricated components, shear walls are integral parts of the building's framework, crucial for maintaining structural integrity in multi-story constructions.

Key Differences Between Shear Panels and Shear Walls

Shear panels are typically thin, flat structural elements designed to resist in-plane lateral forces, often made of plywood or metal, and used in light-frame construction. Shear walls are more robust, vertical cantilever walls composed of materials like reinforced concrete or masonry, offering substantial stiffness and strength for lateral load resistance in buildings. The key difference lies in their structural capacity: shear walls provide higher load-bearing capability and stiffness, while shear panels offer simpler, cost-effective solutions for moderate lateral forces.

Structural Functions and Applications

Shear panels and shear walls both serve critical roles in resisting lateral forces within structural systems, but shear panels are typically lighter, prefabricated elements used to reinforce specific sections, enhancing rigidity and reducing drift in framed structures. Shear walls are full-height, continuous vertical elements integrated into the building's frame, providing substantial lateral load resistance and stability, especially in high-rise buildings and seismic zones. Applications for shear panels often include retrofitting and localized strengthening, while shear walls are essential in new construction for comprehensive lateral support and load distribution.

Materials Used for Shear Panels vs Shear Walls

Shear panels are typically constructed using plywood, oriented strand board (OSB), or metal sheets, which provide flexibility and ease of installation in wood-frame structures. In contrast, shear walls often utilize reinforced concrete, masonry, or steel framing materials to offer enhanced rigidity and load-bearing capacity in both residential and commercial buildings. The choice of materials directly impacts the structural performance, cost, and application suitability of shear panels versus shear walls in seismic and lateral load resistance.

Design Considerations and Standards

Shear panels and shear walls both resist lateral forces, but shear panels are typically used in timber-framed structures while shear walls are common in concrete and masonry buildings, influencing material selection and structural detailing. Design considerations for shear panels emphasize panel thickness, fastening methods, and stiffness to meet performance criteria outlined in standards like APA PRG 320, whereas shear wall design adheres to codes such as the International Building Code (IBC) and ASCE 7, focusing on boundary elements, reinforcement detailing, and load path continuity. Compliance with these standards ensures seismic and wind load resistance, structural integrity, and occupant safety in varying applications.

Advantages and Limitations

Shear panels offer ease of installation and flexibility in design, making them ideal for lightweight structures with moderate lateral load resistance, but they generally provide less stiffness compared to shear walls. Shear walls deliver superior strength and stiffness, enhancing a building's ability to resist seismic and wind forces, yet they require more materials and can limit architectural freedom due to their rigidity. Both systems are essential in structural engineering, with shear panels favored for cost-effective solutions and shear walls chosen for maximum durability and lateral load performance.

Common Uses in Modern Construction

Shear panels are commonly used in light-frame construction for residential and low-rise buildings, providing lateral stiffness and resistance against wind and seismic forces by distributing loads across the frame. Shear walls, often constructed with reinforced concrete or masonry, are prevalent in high-rise buildings and industrial structures where higher load-bearing capacity and rigidity are required to resist lateral loads. Both systems play critical roles in structural stability, with shear panels favored for cost-effective, quick installations and shear walls preferred for robust, long-span applications.

Conclusion: Choosing Between Shear Panel and Shear Wall

Shear walls provide superior lateral load resistance and are ideal for buildings requiring robust seismic and wind protection. Shear panels offer a lightweight, flexible alternative for applications with limited space or budget constraints. The choice depends on structural demands, architectural considerations, and project-specific performance criteria.

Shear panel Infographic

libterm.com

libterm.com