A tubular shaft offers superior strength-to-weight ratio compared to solid shafts, making it ideal for applications requiring high torque and reduced weight. Its hollow structure enhances resistance to bending and torsional stress, improving overall mechanical efficiency. Discover how selecting the right tubular shaft can optimize your machinery's performance in the full article.

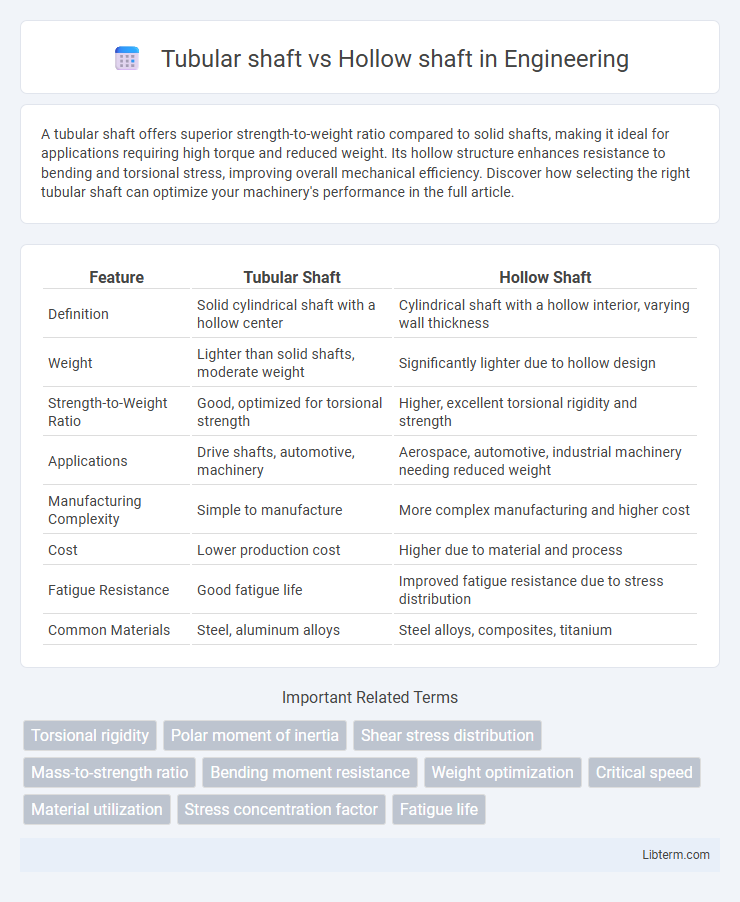

Table of Comparison

| Feature | Tubular Shaft | Hollow Shaft |

|---|---|---|

| Definition | Solid cylindrical shaft with a hollow center | Cylindrical shaft with a hollow interior, varying wall thickness |

| Weight | Lighter than solid shafts, moderate weight | Significantly lighter due to hollow design |

| Strength-to-Weight Ratio | Good, optimized for torsional strength | Higher, excellent torsional rigidity and strength |

| Applications | Drive shafts, automotive, machinery | Aerospace, automotive, industrial machinery needing reduced weight |

| Manufacturing Complexity | Simple to manufacture | More complex manufacturing and higher cost |

| Cost | Lower production cost | Higher due to material and process |

| Fatigue Resistance | Good fatigue life | Improved fatigue resistance due to stress distribution |

| Common Materials | Steel, aluminum alloys | Steel alloys, composites, titanium |

Introduction to Shafts: Tubular vs. Hollow

Tubular shafts offer a high strength-to-weight ratio due to their geometric design, making them ideal for applications requiring reduced weight without compromising structural integrity. Hollow shafts provide excellent torsional rigidity and are cost-effective to manufacture, making them suitable for power transmission in automotive and industrial machinery. Both types optimize mechanical performance in rotating systems, with tubular shafts typically preferred for lightweight constructions and hollow shafts for balance between strength and material efficiency.

Structural Differences: Tubular Shaft vs. Hollow Shaft

The structural differences between tubular shafts and hollow shafts primarily involve their geometry and strength-to-weight ratio. Tubular shafts have a uniform hollow cylindrical shape allowing for high torsional rigidity and resistance to bending while minimizing weight. Hollow shafts, often thicker-walled and sometimes non-uniform in design, provide enhanced load-bearing capacity and improved durability under heavy stress conditions.

Material Selection and Composition

Tubular shafts are typically made from high-strength steel alloys such as chromium-molybdenum or carbon steel, offering an excellent strength-to-weight ratio and enhanced resistance to torsional stress due to their hollow geometry. Hollow shafts often utilize materials like stainless steel or aluminum alloys that provide corrosion resistance and reduced weight, making them suitable for applications requiring lower inertia and improved fatigue life. Material selection depends on application-specific requirements including load conditions, environmental exposure, and manufacturing considerations, with tubular shafts favoring rigidity and hollow shafts prioritizing weight reduction and flexibility.

Weight Comparison: Efficiency and Performance

Tubular shafts offer significantly lower weight compared to solid hollow shafts, enhancing efficiency through reduced rotational inertia and improved dynamic balance. This weight advantage translates to better fuel economy and accelerated response in automotive and aerospace applications. Hollow shafts, while robust, generally carry more mass, which can negatively impact energy consumption and overall performance.

Strength and Load-Bearing Capacity

Tubular shafts offer higher strength-to-weight ratios compared to hollow shafts, making them more efficient in resisting torsional and bending loads. Hollow shafts, while lighter than solid shafts, generally have lower load-bearing capacity due to their reduced cross-sectional area but provide better rigidity than solid shafts of the same weight. Engineering applications often prefer tubular shafts when maximizing strength and load capacity is critical, especially in automotive and aerospace industries.

Torsional Rigidity and Flexural Strength

Tubular shafts exhibit higher torsional rigidity compared to hollow shafts of the same weight due to their greater polar moment of inertia, enhancing resistance to twisting under applied torque. Hollow shafts generally provide superior flexural strength because their material distribution offers better resistance to bending stresses, especially in applications with significant bending loads. Selecting between tubular and hollow shafts depends on the specific demands for torsional stiffness or bending strength in mechanical design.

Applications in Engineering and Industry

Tubular shafts are widely used in automotive and aerospace engineering due to their high strength-to-weight ratio, making them ideal for drive shafts and structural components requiring torsional rigidity. Hollow shafts find extensive applications in mechanical engineering and manufacturing industries where reduced weight and enhanced fatigue resistance are crucial, such as in turbine rotors, conveyor systems, and heavy machinery. Both shaft types optimize performance by balancing strength, weight, and material efficiency, tailored to specific industrial demands.

Manufacturing Processes and Costs

Tubular shafts are typically manufactured using seamless or welded pipe rolling processes, which reduce material usage and lower costs compared to solid shafts. Hollow shafts require precise machining and heat treatment to maintain strength and durability, increasing manufacturing complexity and expenses. The cost efficiency of tubular shafts stems from lighter weight and less raw material, making them ideal for applications where weight reduction and strength are critical.

Durability and Maintenance Considerations

Tubular shafts offer superior durability due to their high strength-to-weight ratio, which reduces stress concentrations and resists bending and torsional loads effectively. Hollow shafts, while lighter, may require more frequent inspection and maintenance to monitor for internal corrosion or fatigue cracks, especially in corrosive environments. Maintenance of tubular shafts generally involves less frequent intervention, enhancing operational efficiency in heavy-duty applications.

Choosing the Right Shaft for Your Application

Choosing the right shaft for your application depends on factors such as weight, strength, and torque requirements. Tubular shafts offer a high strength-to-weight ratio, making them ideal for applications needing rigidity with reduced mass, while hollow shafts provide excellent torsional stiffness and fatigue resistance, suitable for dynamic loads. Evaluating the operational environment and mechanical demands ensures optimal shaft selection for durability and performance.

Tubular shaft Infographic

libterm.com

libterm.com