Strain occurs when excessive force is applied to muscles or tendons, leading to pain, inflammation, and limited movement. Proper rest, stretching, and supportive treatments are essential to speed up recovery and prevent further injury. Discover effective strategies to manage and heal strains by reading the rest of the article.

Table of Comparison

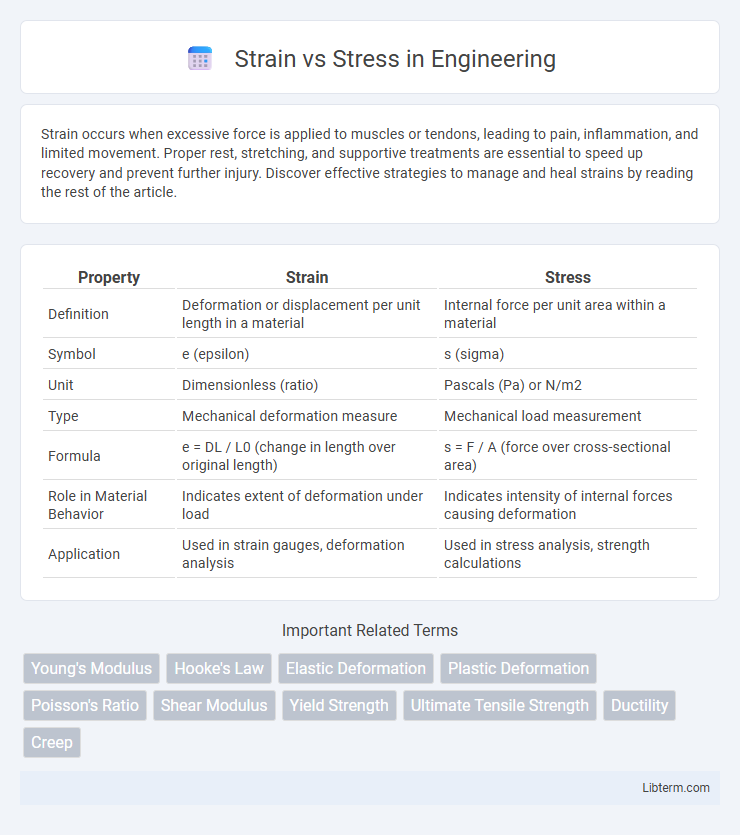

| Property | Strain | Stress |

|---|---|---|

| Definition | Deformation or displacement per unit length in a material | Internal force per unit area within a material |

| Symbol | e (epsilon) | s (sigma) |

| Unit | Dimensionless (ratio) | Pascals (Pa) or N/m2 |

| Type | Mechanical deformation measure | Mechanical load measurement |

| Formula | e = DL / L0 (change in length over original length) | s = F / A (force over cross-sectional area) |

| Role in Material Behavior | Indicates extent of deformation under load | Indicates intensity of internal forces causing deformation |

| Application | Used in strain gauges, deformation analysis | Used in stress analysis, strength calculations |

Understanding the Basics: What is Stress?

Stress is a measure of internal force exerted per unit area within a material, typically expressed in pascals (Pa). It arises when external forces or loads are applied, causing molecules to experience tension, compression, or shear. Understanding stress is essential for analyzing how materials deform and fail under different loading conditions in engineering and materials science.

Defining Strain: A Closer Look

Strain is the measure of deformation representing the displacement between particles in a material body relative to a reference length. It is a dimensionless quantity expressed as the ratio of change in length to the original length, indicating how much a material stretches or compresses under applied stress. Understanding strain is crucial for analyzing material behavior under various loads and predicting structural performance.

Fundamental Differences Between Strain and Stress

Stress is the internal force per unit area within materials caused by externally applied forces, measured in pascals (Pa), while strain is the deformation or displacement per unit length resulting from stress, expressed as a dimensionless ratio or percentage. Stress quantifies the intensity of internal forces resisting deformation, whereas strain quantifies the actual deformation experienced by the material. Understanding the fundamental difference between stress as a measure of force and strain as a measure of deformation is crucial in material science and structural engineering for predicting material behavior and failure.

Types of Stress in Materials

Types of stress in materials include tensile, compressive, shear, torsional, and thermal stress, each affecting materials differently under various load conditions. Tensile stress involves forces pulling material apart, causing elongation, while compressive stress results from forces pushing material together, leading to shortening or crushing. Shear stress acts parallel to the surface, causing sliding layers, torsional stress twists the material around its axis, and thermal stress arises from temperature changes causing expansion or contraction.

Various Forms of Strain

Strain measures the deformation of a material under applied stress, categorized into elastic, plastic, and volumetric forms, each describing reversible, permanent, and volume-changing deformations respectively. Elastic strain occurs when a material returns to its original shape after stress removal, while plastic strain results in permanent shape alteration beyond the yield point. Volumetric strain quantifies changes in material volume under uniform pressure, critical in understanding compressibility in solids and fluids.

Stress-Strain Relationship Explained

The stress-strain relationship describes how materials deform under applied force, where stress measures internal resistance per unit area and strain quantifies the resulting deformation. This relationship is typically linear in the elastic region, governed by Hooke's Law, stating stress is proportional to strain with the modulus of elasticity as the constant of proportionality. Beyond the elastic limit, materials exhibit plastic deformation, where stress and strain no longer follow a linear pattern, leading to permanent changes in shape or failure.

Importance of Stress and Strain in Engineering

Stress quantifies the internal forces per unit area within materials under load, while strain measures the deformation resulting from these forces. Accurate assessment of stress and strain is crucial in engineering to ensure structural integrity, safety, and performance of components under various operational conditions. Engineers rely on these parameters to design materials and structures that withstand mechanical loads without failure or excessive deformation.

Factors Affecting Stress and Strain

Stress and strain are influenced by factors such as material properties, temperature, and the type of applied force. The elasticity, ductility, and hardness of a material determine how it deforms under stress, while temperature variations can alter its strength and flexibility. The magnitude, direction, and duration of the applied load also critically affect the resulting stress and strain within the material.

Real-World Applications: Stress vs Strain

Stress and strain are fundamental concepts in engineering and materials science critical for designing safe structures and machinery. Stress measures the internal forces per unit area within materials under load, while strain quantifies the resultant deformation or displacement relative to the original dimensions. Real-world applications include evaluating bridge durability under traffic loads, assessing aircraft wing flexibility to withstand aerodynamic forces, and ensuring medical implants maintain integrity within biomechanical environments.

Measuring and Calculating Stress and Strain

Stress is measured as force applied per unit area, typically expressed in pascals (Pa), using devices like load cells and strain gauges to quantify the internal forces. Strain is calculated as the ratio of deformation or displacement to the original length, often determined through extensometers or digital image correlation techniques. Accurate measurement and calculation of stress and strain are crucial in materials science to predict mechanical behavior under various loading conditions.

Strain Infographic

libterm.com

libterm.com