Single-point cutting involves the use of a single cutting edge tool to remove material from a workpiece, commonly seen in turning, shaping, or planning operations. This machining process is essential for producing precise dimensions and smooth surface finishes in metalworking and manufacturing. Discover how single-point cutting can enhance Your machining efficiency by reading the full article.

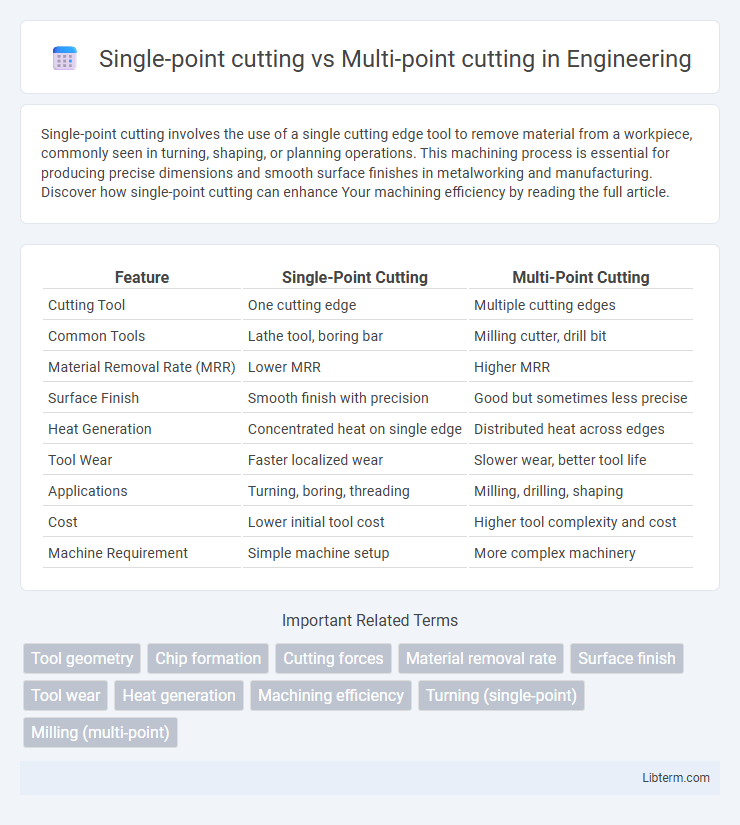

Table of Comparison

| Feature | Single-Point Cutting | Multi-Point Cutting |

|---|---|---|

| Cutting Tool | One cutting edge | Multiple cutting edges |

| Common Tools | Lathe tool, boring bar | Milling cutter, drill bit |

| Material Removal Rate (MRR) | Lower MRR | Higher MRR |

| Surface Finish | Smooth finish with precision | Good but sometimes less precise |

| Heat Generation | Concentrated heat on single edge | Distributed heat across edges |

| Tool Wear | Faster localized wear | Slower wear, better tool life |

| Applications | Turning, boring, threading | Milling, drilling, shaping |

| Cost | Lower initial tool cost | Higher tool complexity and cost |

| Machine Requirement | Simple machine setup | More complex machinery |

Introduction to Cutting Processes

Single-point cutting involves a single cutting edge to remove material, commonly used in turning and shaping operations, while multi-point cutting employs multiple cutting edges simultaneously, as seen in milling and drilling processes. Single-point cutting typically produces continuous chips and offers greater control over the cut, whereas multi-point cutting enhances material removal rates and efficiency. These fundamental differences impact surface finish, tool wear, and overall machining productivity in various manufacturing applications.

Overview of Single-Point Cutting

Single-point cutting involves a single cutting edge removing material from a workpiece, commonly used in turning, shaping, and boring operations. This method allows for precise control and is ideal for creating detailed features on cylindrical or flat surfaces. Single-point cutting tools typically experience higher cutting forces and wear, necessitating robust tool materials and careful process parameters.

Overview of Multi-Point Cutting

Multi-point cutting involves using cutting tools with multiple cutting edges that simultaneously engage the workpiece, enhancing material removal rates and efficiency. This process is commonly applied in milling and drilling operations, where the distribution of cutting forces across several points reduces tool wear and improves surface finish. The complex geometry of multi-point tools allows for versatile machining capabilities and greater productivity compared to single-point cutting methods.

Key Differences Between Single-Point and Multi-Point Cutting

Single-point cutting tools feature one cutting edge and are primarily used for turning, shaping, and boring, while multi-point cutting tools have multiple cutting edges suitable for milling and drilling operations. Single-point cutting generates continuous chips and is ideal for precise, low-feed rates, whereas multi-point cutting distributes cutting forces across several edges, allowing higher feed rates and faster material removal. Tool wear patterns and heat dissipation differ significantly; single-point tools experience concentrated wear on the cutting edge, whereas multi-point tools share wear among edges, enhancing tool life and efficiency.

Advantages of Single-Point Cutting

Single-point cutting tools offer enhanced precision and better surface finish due to a single cutting edge directly engaging the workpiece, making them ideal for turning and boring operations. They provide simpler tool geometry, which reduces manufacturing costs and simplifies tool sharpening and maintenance. The focused cutting action allows for efficient chip removal and greater control over cutting forces, resulting in improved machining accuracy and extended tool life.

Benefits of Multi-Point Cutting

Multi-point cutting tools enhance machining efficiency by distributing cutting forces among multiple edges, reducing wear and extending tool life compared to single-point cutting tools. This approach improves surface finish and accuracy due to simultaneous cutting actions and better heat dissipation. Multi-point cutting also allows for higher material removal rates and faster production cycles, making it ideal for high-volume manufacturing.

Typical Applications of Single-Point Tools

Single-point cutting tools are predominantly used in turning, shaping, and boring operations where precision and surface finish are critical, such as in lathe machining of shafts, automotive components, and aerospace parts. These tools excel in producing complex geometries on cylindrical surfaces and are preferred for operations requiring detailed contouring and thread cutting. Multi-point cutting tools, in contrast, are more suited for milling and drilling where higher material removal rates are necessary.

Common Uses of Multi-Point Tools

Multi-point cutting tools, such as milling cutters and drills, are widely used in applications requiring high material removal rates and improved surface finish, including machining complex geometries and mass production of parts. These tools distribute cutting forces across multiple edges, enhancing tool life and efficiency in operations like milling, drilling, and broaching. Industries such as automotive manufacturing and aerospace rely heavily on multi-point cutting for precision and productivity in metalworking processes.

Factors Influencing Tool Selection

Tool selection between single-point and multi-point cutting depends on material type, desired surface finish, and production volume. Single-point cutting tools excel in precision machining of hard materials and complex profiles, while multi-point cutting tools are preferred for higher material removal rates and smoother finishes on softer materials. Considerations also include cutting speed, tool wear resistance, and machine capability to optimize efficiency and tool life.

Summary and Final Comparison

Single-point cutting tools, characterized by a single cutting edge, are typically used in turning operations offering precision and simplicity for tasks like shaping metal or wood. Multi-point cutting tools feature multiple cutting edges, commonly found in milling and drilling processes, increasing efficiency and reducing machining time. While single-point tools excel in detailed, fine work with slower feed rates, multi-point tools provide higher productivity for bulk material removal with enhanced stability and tool life.

Single-point cutting Infographic

libterm.com

libterm.com