Stereolithography (SLA) is an advanced 3D printing technology that uses a laser to cure liquid resin into solid objects with high precision and smooth surface finish. This method is ideal for creating detailed prototypes, intricate designs, and functional parts across industries like healthcare, automotive, and aerospace. Explore the rest of the article to discover how stereolithography can enhance your manufacturing process and product development.

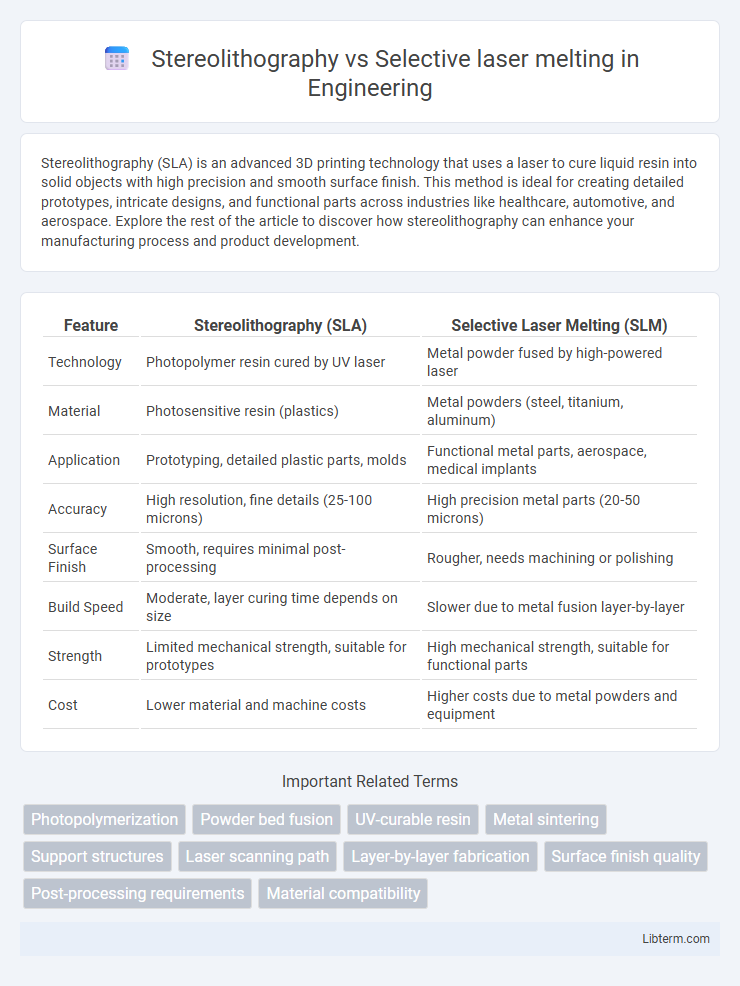

Table of Comparison

| Feature | Stereolithography (SLA) | Selective Laser Melting (SLM) |

|---|---|---|

| Technology | Photopolymer resin cured by UV laser | Metal powder fused by high-powered laser |

| Material | Photosensitive resin (plastics) | Metal powders (steel, titanium, aluminum) |

| Application | Prototyping, detailed plastic parts, molds | Functional metal parts, aerospace, medical implants |

| Accuracy | High resolution, fine details (25-100 microns) | High precision metal parts (20-50 microns) |

| Surface Finish | Smooth, requires minimal post-processing | Rougher, needs machining or polishing |

| Build Speed | Moderate, layer curing time depends on size | Slower due to metal fusion layer-by-layer |

| Strength | Limited mechanical strength, suitable for prototypes | High mechanical strength, suitable for functional parts |

| Cost | Lower material and machine costs | Higher costs due to metal powders and equipment |

Introduction to Additive Manufacturing Technologies

Stereolithography (SLA) and Selective Laser Melting (SLM) are advanced additive manufacturing technologies used for creating complex parts layer by layer from digital models. SLA utilizes a UV laser to cure liquid photopolymer resin, offering high precision and smooth surface finishes, ideal for prototypes and intricate designs. SLM employs a high-power laser to melt and fuse metallic powders, producing dense, functional metal components with excellent mechanical properties for aerospace and automotive industries.

Overview of Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing process that uses a UV laser to cure liquid photopolymer resin layer by layer, producing highly detailed and smooth surface finishes. Unlike Selective Laser Melting (SLM), which melts metal powders, SLA primarily focuses on creating precise plastic prototypes and parts with fine resolution. This technology is widely applied in industries requiring intricate designs, such as dental, jewelry, and rapid prototyping sectors.

Overview of Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is an additive manufacturing technique that uses a high-powered laser to fuse metallic powders layer by layer, enabling the creation of fully dense and complex metal parts with fine details and high mechanical properties. Unlike Stereolithography (SLA), which primarily fabricates resin-based prototypes through photopolymerization, SLM is suited for producing functional metal components in aerospace, medical implants, and automotive industries. The process parameters in SLM, including laser power, scan speed, and powder characteristics, critically influence part quality, density, and mechanical performance.

Key Differences Between SLA and SLM

Stereolithography (SLA) uses a UV laser to cure liquid photopolymer resin layer by layer, producing highly detailed and smooth surface finishes ideal for prototypes and intricate designs. Selective Laser Melting (SLM) employs a high-powered laser to fully melt metal powder, enabling the creation of dense, functional metal parts with superior mechanical properties for aerospace and medical applications. While SLA excels in precision and surface quality, SLM offers metal part manufacturing with complex geometries and high structural integrity.

Materials Used in SLA and SLM

Stereolithography (SLA) primarily uses photopolymer resins that cure when exposed to ultraviolet light, offering high precision and smooth surface finishes ideal for prototypes and detailed models. Selective Laser Melting (SLM) utilizes metal powders such as stainless steel, titanium, aluminum, and cobalt-chrome alloys, enabling the production of fully dense, functional metal parts with excellent mechanical properties. The distinct material bases--liquid photopolymers for SLA and metal powders for SLM--define their applications in additive manufacturing, with SLA suited for intricate plastic parts and SLM for durable metal components.

Printing Process and Technology Comparison

Stereolithography (SLA) uses a UV laser to cure liquid photopolymer resin layer by layer, producing highly detailed and smooth surface finishes ideal for prototypes and complex geometries. Selective Laser Melting (SLM) employs a high-power laser to fully melt metal powder particles, creating fully dense and mechanically robust metal parts suitable for aerospace and medical applications. The key distinction lies in SLA's photopolymer resin curing process versus SLM's metal powder fusion, impacting material properties, resolution, and end-use functionality.

Advantages and Limitations of SLA

Stereolithography (SLA) offers high precision and smooth surface finishes ideal for detailed prototypes and complex geometries, leveraging photopolymer resins cured by ultraviolet lasers. Its limitations include lower mechanical strength compared to Selective Laser Melting (SLM) and restricted material options, predominantly photopolymers versus metal powders used in SLM. SLA's cost-effectiveness and speed benefit rapid prototyping, while SLM excels in producing robust, functional metal parts with superior structural properties.

Advantages and Limitations of SLM

Selective Laser Melting (SLM) offers superior mechanical properties and material density compared to Stereolithography (SLA), enabling the production of fully functional metal parts with complex geometries and high precision. SLM's main limitations include higher operational costs, prolonged build times, and the necessity for post-processing to remove residual stresses and support structures, which can affect overall efficiency. Unlike SLA, which uses photopolymer resins and is ideal for rapid prototyping and surface finish quality, SLM excels in manufacturing robust metal components but requires advanced equipment and skilled operators.

Common Applications of SLA vs SLM

Stereolithography (SLA) is primarily used for producing high-resolution prototypes, dental molds, and intricate medical devices due to its precision and smooth surface finish. Selective Laser Melting (SLM) is favored in aerospace, automotive, and metal tooling industries for creating complex, fully dense metal parts with excellent mechanical properties. Both technologies serve distinct manufacturing needs, with SLA excelling in detail-oriented polymer applications and SLM dominating in metal component fabrication.

Choosing the Right Technology for Your Project

Stereolithography (SLA) excels in producing highly detailed prototypes with smooth surface finishes, ideal for conceptual models and intricate designs, while Selective Laser Melting (SLM) offers superior mechanical properties and dense metal parts suitable for functional end-use components and aerospace applications. When choosing the right technology, consider factors such as material requirements, part complexity, and performance specifications, as SLA primarily processes photopolymer resins and SLM works with metal powders like titanium and stainless steel. Budget constraints and production volume also influence decision-making, with SLA being more cost-effective for rapid prototyping and SLM preferred for durable, load-bearing parts.

Stereolithography Infographic

libterm.com

libterm.com