Failure Modes and Effects Analysis (FMEA) systematically identifies potential failure points in a process or product to mitigate risks and improve reliability. This method prioritizes failure modes based on their severity, occurrence, and detectability, enabling targeted corrective actions that enhance overall quality. Discover how FMEA can safeguard your operations and drive continuous improvement by reading the rest of the article.

Table of Comparison

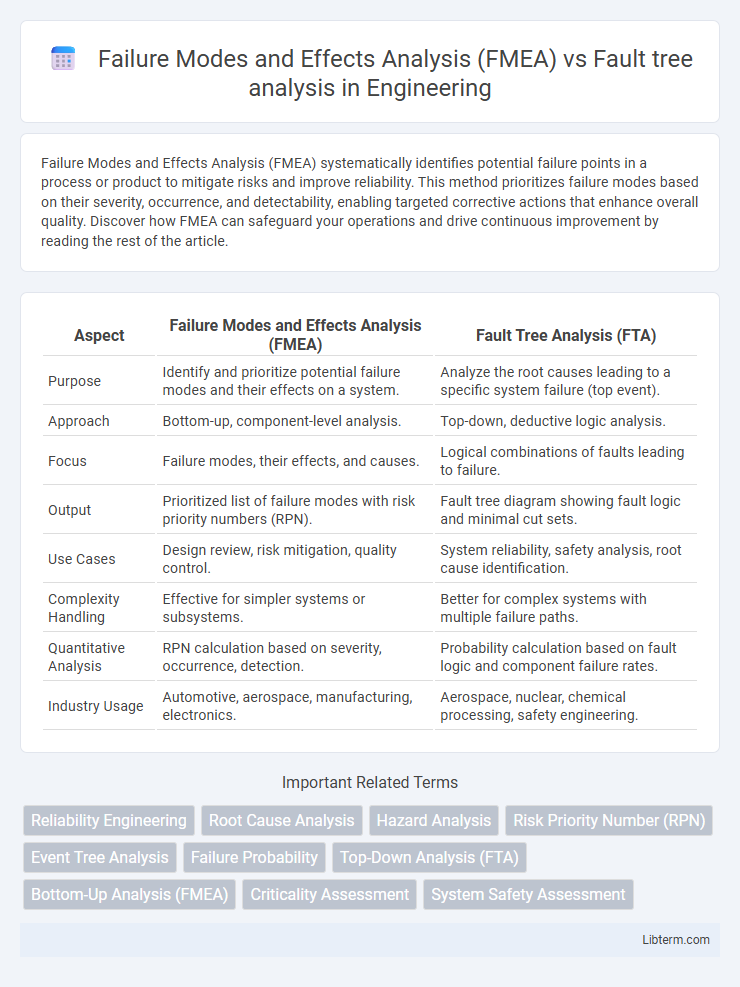

| Aspect | Failure Modes and Effects Analysis (FMEA) | Fault Tree Analysis (FTA) |

|---|---|---|

| Purpose | Identify and prioritize potential failure modes and their effects on a system. | Analyze the root causes leading to a specific system failure (top event). |

| Approach | Bottom-up, component-level analysis. | Top-down, deductive logic analysis. |

| Focus | Failure modes, their effects, and causes. | Logical combinations of faults leading to failure. |

| Output | Prioritized list of failure modes with risk priority numbers (RPN). | Fault tree diagram showing fault logic and minimal cut sets. |

| Use Cases | Design review, risk mitigation, quality control. | System reliability, safety analysis, root cause identification. |

| Complexity Handling | Effective for simpler systems or subsystems. | Better for complex systems with multiple failure paths. |

| Quantitative Analysis | RPN calculation based on severity, occurrence, detection. | Probability calculation based on fault logic and component failure rates. |

| Industry Usage | Automotive, aerospace, manufacturing, electronics. | Aerospace, nuclear, chemical processing, safety engineering. |

Introduction to FMEA and Fault Tree Analysis

Failure Modes and Effects Analysis (FMEA) systematically identifies potential failure points within a process or product to evaluate their impact and prioritize risk mitigation strategies, enhancing reliability and safety. Fault Tree Analysis (FTA) uses a top-down, deductive approach to visually map the pathways leading to a system failure by analyzing logical relationships among various subsystems and component faults. Both methodologies serve as critical tools in risk management, with FMEA emphasizing failure identification and effects, while FTA focuses on failure causation and logical fault relationships.

Definition and Purpose of FMEA

Failure Modes and Effects Analysis (FMEA) is a systematic methodology used to identify potential failure modes within a system, assess their causes and effects, and prioritize them based on risk to improve design reliability and safety. Unlike Fault Tree Analysis (FTA), which uses a top-down approach to analyze system failures through logic diagrams, FMEA provides a bottom-up, proactive process designed to prevent failures by addressing potential issues early in the design or process stages. The primary purpose of FMEA is to enhance product quality, reduce risk, and support decision-making by focusing on failure prevention and mitigation strategies.

Definition and Purpose of Fault Tree Analysis

Fault Tree Analysis (FTA) is a systematic, top-down approach used to identify the root causes of system failures by mapping the logical relationships between faults and their contributing events. Its purpose is to analyze the probability of system failures by visually representing failure pathways, enabling risk assessment and mitigation in complex systems. Unlike FMEA, which examines each component's potential failures individually, FTA focuses on the interaction of events leading to a specific undesired outcome.

Key Differences Between FMEA and Fault Tree Analysis

Failure Modes and Effects Analysis (FMEA) is a bottom-up approach that identifies potential failure modes within a system and assesses their effects on system performance, prioritizing risks based on severity, occurrence, and detection ratings. Fault Tree Analysis (FTA) is a top-down, deductive method that starts with a specific undesired event and works backward to identify all possible causes using logical gates. Key differences include FMEA's focus on individual component failures and proactive risk mitigation, while FTA emphasizes root cause analysis of a predefined system-level failure event.

Methodology: Step-by-Step FMEA Process

Failure Modes and Effects Analysis (FMEA) follows a systematic step-by-step methodology starting with identifying potential failure modes within a system, process, or product. It involves assessing the effects and causes of each failure mode, assigning severity, occurrence, and detection ratings to calculate a Risk Priority Number (RPN) that prioritizes risks for mitigation. This structured approach enables teams to proactively address vulnerabilities, enhance reliability, and improve overall quality by systematically analyzing all possible failures and their impacts before product release or process implementation.

Methodology: Step-by-Step Fault Tree Analysis Process

Fault Tree Analysis (FTA) involves a top-down, deductive reasoning approach starting with defining an undesired event and systematically identifying all possible fault combinations leading to it through logic gates like AND and OR. The process includes constructing the fault tree, quantifying probabilities of basic events, performing qualitative analysis to find minimal cut sets, and evaluating system reliability and risk. This contrasts with FMEA's bottom-up, inductive approach focused on failure modes and their effects on system components without the formalized logic gate structure.

Applications: When to Use FMEA or Fault Tree Analysis

Failure Modes and Effects Analysis (FMEA) excels in early project phases to identify potential failure points in complex systems by assessing individual component risks, making it ideal for design verification and preventive maintenance planning. Fault Tree Analysis (FTA) is preferable for detailed root cause analysis and evaluating the probability of system-level failures, especially in safety-critical industries like aerospace and nuclear power. Selecting between FMEA and FTA depends on whether the goal is to prevent failures proactively (FMEA) or to analyze the causes after failures occur (FTA).

Benefits and Limitations of FMEA

Failure Modes and Effects Analysis (FMEA) offers systematic identification and prioritization of potential failure modes, enhancing preventive maintenance and design improvements by focusing on severity, occurrence, and detection ratings. Its primary benefit lies in early-stage problem detection, fostering risk mitigation before failures occur, but limitations include its reliance on expert judgment and potential for oversight if not continuously updated. Unlike Fault Tree Analysis, which excels in detailed fault-path tracing, FMEA provides a more straightforward, component-level risk assessment, making it suitable for iterative design and operational processes.

Benefits and Limitations of Fault Tree Analysis

Fault Tree Analysis (FTA) offers a systematic approach to identifying root causes of system failures by visually mapping fault pathways, enhancing reliability in complex engineering systems. Its primary benefit lies in enabling quantitative risk assessment through probability calculations, supporting proactive maintenance and safety improvements. Limitations include its dependency on complete and accurate failure data, potential complexity in large systems, and challenges in modeling dynamic interactions that FMEA handles more flexibly.

Choosing the Right Risk Assessment Tool for Your Needs

Failure Modes and Effects Analysis (FMEA) excels in identifying potential failure points and their effects within individual components or processes, making it ideal for detailed, component-level risk assessment. Fault Tree Analysis (FTA) provides a top-down, systematic approach to diagnosing root causes of system-level failures using logic diagrams, which is preferable for complex systems requiring failure causality analysis. Selecting between FMEA and FTA depends on whether the focus is on granular failure detection (FMEA) or understanding overall system failure pathways (FTA) to effectively manage risk.

Failure Modes and Effects Analysis (FMEA) Infographic

libterm.com

libterm.com