Reed relays offer precise switching capabilities with low contact resistance and fast response times, making them ideal for sensitive electronic applications. Their hermetically sealed contacts ensure reliability and long service life, especially in environments where contamination is a concern. Discover how your projects can benefit from the unique advantages of reed relays by exploring the detailed insights in this article.

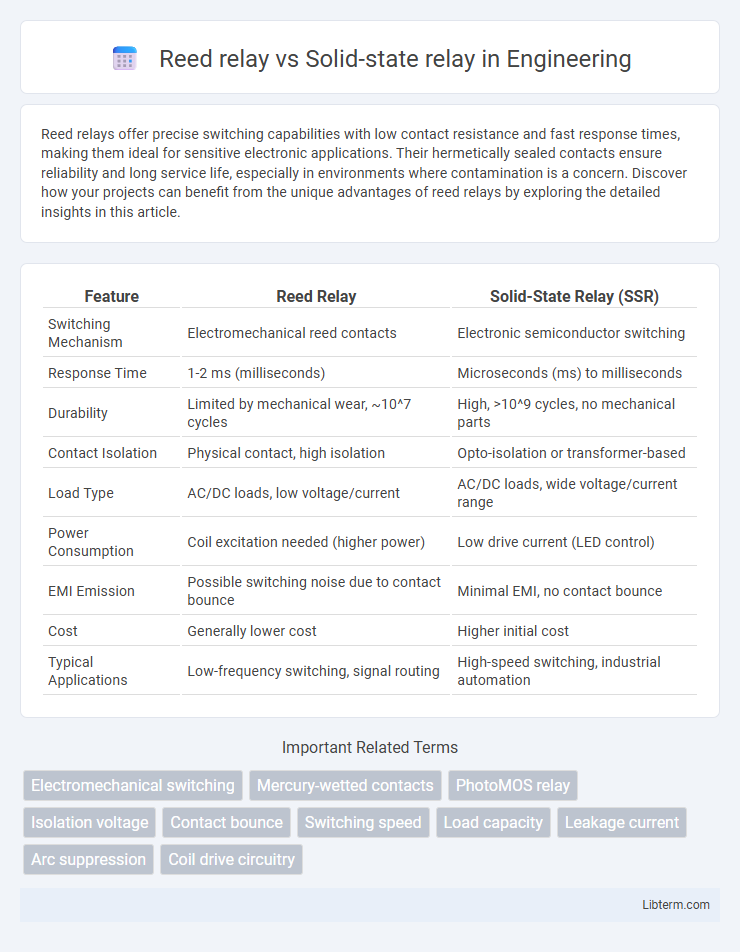

Table of Comparison

| Feature | Reed Relay | Solid-State Relay (SSR) |

|---|---|---|

| Switching Mechanism | Electromechanical reed contacts | Electronic semiconductor switching |

| Response Time | 1-2 ms (milliseconds) | Microseconds (ms) to milliseconds |

| Durability | Limited by mechanical wear, ~10^7 cycles | High, >10^9 cycles, no mechanical parts |

| Contact Isolation | Physical contact, high isolation | Opto-isolation or transformer-based |

| Load Type | AC/DC loads, low voltage/current | AC/DC loads, wide voltage/current range |

| Power Consumption | Coil excitation needed (higher power) | Low drive current (LED control) |

| EMI Emission | Possible switching noise due to contact bounce | Minimal EMI, no contact bounce |

| Cost | Generally lower cost | Higher initial cost |

| Typical Applications | Low-frequency switching, signal routing | High-speed switching, industrial automation |

Introduction to Reed Relays and Solid-State Relays

Reed relays consist of magnetic reed switches enclosed in a glass tube, offering low contact resistance and fast switching ideal for sensitive signal applications. Solid-state relays utilize semiconductor devices such as thyristors or transistors, providing high reliability, no mechanical wear, and silent operation suited for high-speed or harsh environments. Reed relays excel in low-level signal switching with minimal contact contamination, while solid-state relays handle higher currents and voltages without physical contact degradation.

Basic Operating Principles

Reed relays operate using an electromagnetic coil that generates a magnetic field to physically close or open metal reed contacts housed within a sealed glass tube, ensuring low contact resistance and fast switching. Solid-state relays (SSRs) utilize semiconductor components like thyristors, triacs, or MOSFETs to switch electrical loads without moving parts, providing silent operation and high durability. The fundamental difference lies in reed relays' mechanical switching versus SSRs' solid-state electronic switching technology.

Key Differences Between Reed Relays and Solid-State Relays

Reed relays utilize mechanical reed switches encapsulated in a glass envelope, offering low contact resistance and fast switching ideal for sensitive signal applications. Solid-state relays employ semiconductor devices such as thyristors or transistors to provide noise-free, vibration-resistant switching with longer operational life and faster response times. Unlike reed relays, solid-state relays support higher switching frequencies and are more suitable for high-power loads but lack the galvanic isolation and ultra-low on-resistance characteristic of reed relays.

Performance and Reliability Comparison

Reed relays offer low contact resistance and fast switching speeds, making them ideal for precision low-level signal applications, while solid-state relays excel with no mechanical wear and longer operational lifespans due to their semiconductor-based switching. In terms of reliability, reed relays are prone to contact degradation and limited switching cycles, whereas solid-state relays provide superior durability with high immunity to shock and vibration. Performance-wise, solid-state relays handle higher switching frequencies and offer quieter operation, but reed relays maintain advantages in isolation and low leakage current for sensitive electronic circuits.

Switching Speed and Response Time

Reed relays offer switching speeds typically in the range of 0.5 to 2 milliseconds, making them suitable for applications requiring fast mechanical switching with low contact resistance. Solid-state relays (SSRs) provide significantly faster response times, often in microseconds, due to their semiconductor-based switching elements that eliminate physical contacts. The rapid switching and virtually instantaneous response of SSRs are ideal for high-frequency or precision control systems where speed and reliability are critical.

Lifespan and Durability

Reed relays offer an exceptionally long mechanical lifespan, often exceeding 10 million operations due to their sealed contacts, which are protected from environmental contaminants. Solid-state relays provide superior durability with no moving parts, resulting in virtually unlimited switching cycles and excellent resistance to shock and vibration. While reed relays excel in low-current, precise switching applications, solid-state relays deliver enhanced longevity in high-frequency and harsh industrial environments.

Application Suitability and Use Cases

Reed relays excel in low-level signal switching, making them ideal for test and measurement equipment, medical instruments, and telecommunications where fast, reliable, and low-current operations are critical. Solid-state relays suit high-power applications such as industrial automation, motor control, and lighting systems due to their durability, silent operation, and fast switching without mechanical wear. The choice depends on the specific electrical load, switching speed requirements, and environmental conditions involved in the application.

Power Consumption and Efficiency

Reed relays consume significantly less power than solid-state relays since they require only a small coil current to actuate, making them highly efficient in low-power applications. Solid-state relays, while offering faster switching and longer life, typically draw continuous control current and experience higher power dissipation due to their semiconductor components. The efficiency advantage of reed relays is particularly noticeable in battery-powered and energy-sensitive devices where minimal power consumption is critical.

Cost Factors and Economic Considerations

Reed relays typically have higher initial costs due to their mechanical components and specialized manufacturing processes, making them less economical for high-volume or low-cost applications. Solid-state relays (SSRs) offer lower production costs and longer lifespans, reducing maintenance expenses and making them more cost-effective for continuous or high-frequency switching. When evaluating total cost of ownership, factors such as energy efficiency, durability, and switching speed also influence the economic advantage of choosing SSRs over reed relays.

Choosing the Right Relay for Your Application

Reed relays offer fast switching speeds, low contact resistance, and excellent isolation, making them ideal for sensitive signal applications requiring minimal electrical noise. Solid-state relays provide high durability, silent operation, and longer lifespan with no mechanical parts, suitable for high switching frequency and industrial automation environments. Selecting the right relay depends on factors including load type, switching speed, electrical noise tolerance, and environmental conditions specific to your application.

Reed relay Infographic

libterm.com

libterm.com