Howe truss is a popular structural framework commonly used in bridges and roofs, consisting of diagonal timber or steel members slanting towards the center and vertical iron rods in tension. This design efficiently distributes loads, providing excellent strength and stability for spanning large distances. Explore the rest of this article to understand how the Howe truss can benefit your construction projects.

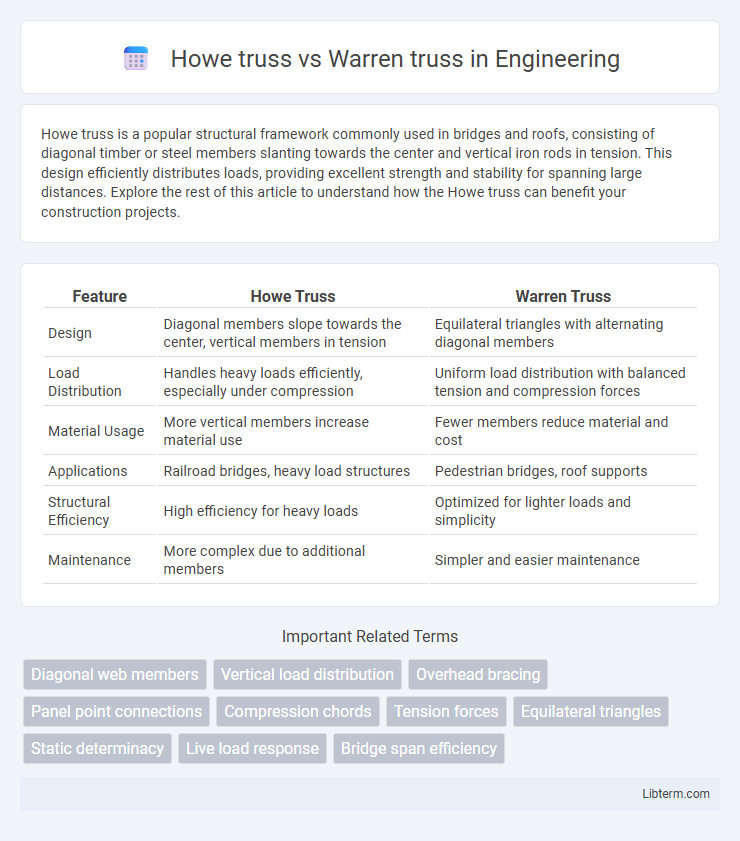

Table of Comparison

| Feature | Howe Truss | Warren Truss |

|---|---|---|

| Design | Diagonal members slope towards the center, vertical members in tension | Equilateral triangles with alternating diagonal members |

| Load Distribution | Handles heavy loads efficiently, especially under compression | Uniform load distribution with balanced tension and compression forces |

| Material Usage | More vertical members increase material use | Fewer members reduce material and cost |

| Applications | Railroad bridges, heavy load structures | Pedestrian bridges, roof supports |

| Structural Efficiency | High efficiency for heavy loads | Optimized for lighter loads and simplicity |

| Maintenance | More complex due to additional members | Simpler and easier maintenance |

Introduction to Truss Bridge Designs

Howe truss and Warren truss are key designs in truss bridge construction, distinguished by their structural geometry and load distribution. The Howe truss features diagonal members that slope towards the center and vertical members in tension, making it efficient for heavy loads and timber construction. In contrast, the Warren truss uses equilateral triangles with members alternating in tension and compression, offering material efficiency and a balanced load distribution for steel bridges.

Overview of Howe Truss

The Howe truss features diagonal members that slope toward the center and are in compression, with vertical members under tension, making it ideal for wooden bridges and heavy loads. Its design distributes forces efficiently through timber and iron or steel rods, enhancing durability and structural integrity. Commonly used in railroad bridges during the 19th century, the Howe truss remains favored for its simplicity and strong load-bearing capabilities.

Overview of Warren Truss

The Warren truss features a series of equilateral triangles that distribute loads evenly, making it highly efficient in resisting both compression and tension forces. This design reduces material usage while maintaining structural integrity, ideal for bridges and roof supports where weight optimization is crucial. Its simplicity and uniform stress distribution contribute to easier fabrication and maintenance compared to other truss types like the Howe truss.

Key Structural Differences

The Howe truss features vertical members in tension and diagonal members in compression, optimizing it for heavy loads and stability in bridge construction. In contrast, the Warren truss utilizes equilateral triangles with members alternating between tension and compression, providing uniform stress distribution and material efficiency. These structural differences influence their respective applications, with Howe trusses preferred for timber and heavier loads, while Warren trusses suit steel frameworks and moderate spans.

Load Distribution and Efficiency

Howe trusses distribute loads through vertical tension members and diagonal compression members, making them highly effective for heavier loads and longer spans. Warren trusses use equilateral triangles with members experiencing alternating tension and compression, providing efficient material use and uniform load distribution. In terms of efficiency, Warren trusses often require less material due to their simpler design, while Howe trusses excel in applications with significant vertical load demands.

Material Usage and Construction Methods

Howe trusses primarily use timber for chords and iron or steel for vertical and diagonal web members, optimizing material distribution by placing timber in compression and metal in tension, which suits traditional timber bridge construction. Warren trusses employ a simpler arrangement of equilateral triangles using uniform steel sections, minimizing material usage by evenly distributing forces through diagonal members without verticals, streamlining fabrication and assembly. Construction methods for Howe trusses often involve complex joinery and bolted connections tailored to wood and metal components, whereas Warren trusses favor welded or bolted steel connections enabling faster, modular steel construction.

Durability and Maintenance Considerations

Howe trusses, featuring vertical members in compression and diagonals in tension, typically offer enhanced durability in wooden structures due to efficient load distribution, yet require more frequent inspection and maintenance of tension members to prevent corrosion. Warren trusses, characterized by equilateral triangles with members alternating between tension and compression, provide simplified maintenance with fewer components and easier access but may experience faster wear in metal connections under dynamic loads. Choosing between them depends on the material type, environmental exposure, and maintenance resources available to ensure long-term structural integrity.

Common Applications and Use Cases

The Howe truss is commonly used in railroad bridges and heavy-load structures due to its diagonal members in compression and verticals in tension, providing strong support for heavy traffic and long spans. The Warren truss, characterized by equilateral triangles and alternating tension and compression members, is often applied in highway bridges, roof supports, and lightweight industrial buildings where material efficiency and ease of construction are priorities. Both truss types serve critical roles in civil engineering, with the Howe truss favored for heavier, static loads and the Warren truss ideal for dynamic loads requiring balanced stress distribution.

Cost Comparison

Howe truss generally incurs higher material costs due to its use of vertical members and diagonals, often requiring more steel or timber compared to the Warren truss. The Warren truss offers a cost-efficient design by utilizing equilateral triangles that distribute loads evenly, reducing the need for extra material and labor. Maintenance expenses for Howe trusses can be higher because its design has more components prone to wear, while the simpler Warren truss tends to lower long-term operational costs.

Choosing Between Howe and Warren Truss

Choosing between Howe and Warren truss designs depends on load distribution and application requirements. Howe trusses feature vertical members in compression and diagonal members in tension, making them ideal for heavy, uneven loads and railroad bridges. Warren trusses use equilateral triangles with members alternately in tension and compression, offering material efficiency and suitability for shorter spans and lighter loads in highway bridges.

Howe truss Infographic

libterm.com

libterm.com