A potentiometer is an essential electronic component used to measure and adjust voltage levels by varying resistance within a circuit. It plays a critical role in applications ranging from audio volume control to tuning and calibration in various electronic devices. Discover how a potentiometer works and how you can effectively use it in your projects by reading the rest of this article.

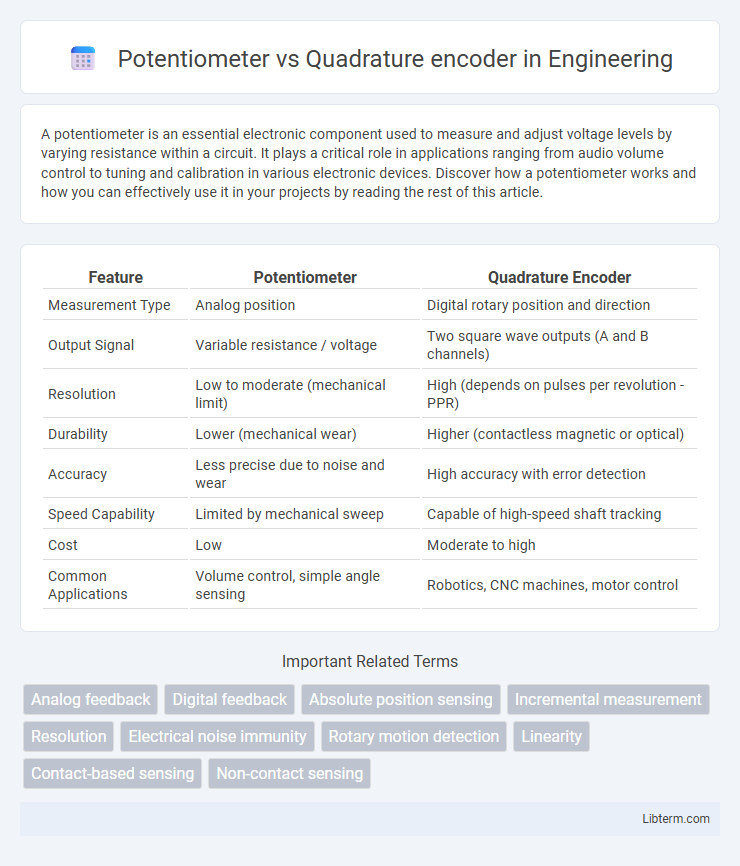

Table of Comparison

| Feature | Potentiometer | Quadrature Encoder |

|---|---|---|

| Measurement Type | Analog position | Digital rotary position and direction |

| Output Signal | Variable resistance / voltage | Two square wave outputs (A and B channels) |

| Resolution | Low to moderate (mechanical limit) | High (depends on pulses per revolution - PPR) |

| Durability | Lower (mechanical wear) | Higher (contactless magnetic or optical) |

| Accuracy | Less precise due to noise and wear | High accuracy with error detection |

| Speed Capability | Limited by mechanical sweep | Capable of high-speed shaft tracking |

| Cost | Low | Moderate to high |

| Common Applications | Volume control, simple angle sensing | Robotics, CNC machines, motor control |

Introduction to Potentiometers and Quadrature Encoders

Potentiometers are variable resistors used to measure angular or linear position by changing resistance proportionally to the movement of a wiper along a resistive element. Quadrature encoders provide precise digital signals representing rotational displacement and direction through two output channels 90 degrees out of phase, enabling high-resolution position and speed sensing. Both devices serve essential roles in motion control systems, with potentiometers offering analog position feedback and quadrature encoders delivering accurate digital measurements for advanced control applications.

Basic Working Principles

A potentiometer operates by varying resistance through a sliding contact that moves along a resistive element, producing an analog voltage proportional to the position. In contrast, a quadrature encoder uses two output channels producing square waves offset by 90 degrees, enabling the detection of both position and direction through digital pulse counting. Potentiometers provide absolute position measurements with simpler analog signals, while quadrature encoders deliver incremental position and speed information with higher resolution using digital quadrature signals.

Key Differences in Operation

Potentiometers measure angular position by varying resistance in a continuous analog signal, providing absolute position feedback with simple wiring but limited resolution and wear over time. Quadrature encoders generate digital pulse signals through optical or magnetic sensors to detect rotational position and direction with high precision and durability, enabling incremental feedback ideal for motion control. The fundamental operational difference lies in potentiometers offering fixed-range absolute analog output, while quadrature encoders provide incremental digital signals that require interpretation for precise positional data.

Accuracy and Resolution Comparison

Potentiometers typically offer lower accuracy and limited resolution due to their analog nature and mechanical wear, with resolution often restricted to a few degrees. Quadrature encoders provide significantly higher precision and resolution by generating digital pulses, allowing measurement down to fractions of a degree or even arcminutes. The encoder's ability to deliver consistent, repeatable position feedback surpasses potentiometers, making them ideal for applications requiring fine accuracy and high resolution.

Durability and Lifespan

Potentiometers typically have a shorter lifespan due to mechanical wear from continuous wiper contact, often lasting around 1 million cycles, whereas quadrature encoders, especially optical or magnetic types, offer enhanced durability with lifespans exceeding 100 million cycles. The sealed and contactless design of quadrature encoders reduces susceptibility to dust, dirt, and moisture, significantly increasing reliability in harsh environments compared to potentiometers. Maintenance demands for potentiometers are higher since their resistive elements degrade over time, while quadrature encoders generally require less frequent servicing due to their robust construction.

Cost Efficiency and Availability

Potentiometers generally offer lower initial costs and simpler integration, making them highly cost-efficient for basic position sensing applications. Quadrature encoders, while typically more expensive upfront, provide higher precision and durability, often resulting in better long-term value for dynamic or industrial environments. Potentiometers are widely available in standard sizes and configurations, whereas quadrature encoders may require more specialized sourcing depending on resolution and interface requirements.

Application Areas and Use Cases

Potentiometers are widely used in applications requiring precise angular position measurement, such as volume control in audio equipment and throttle sensing in automotive systems due to their simplicity and cost-effectiveness. Quadrature encoders excel in industrial automation and robotics, providing high-resolution feedback for motor control, robotics joint positioning, and CNC machinery with their ability to detect both position and direction of rotation. The choice depends on the required accuracy, environmental conditions, and dynamic response, with potentiometers favoring low-speed, analog settings and encoders suited for high-speed, digital precision tasks.

Installation Requirements

Potentiometers require simple wiring and mechanical alignment, typically mounted on a rotating shaft with a three-wire connection for voltage measurement. Quadrature encoders demand more precise installation with correct shaft coupling and alignment to avoid signal errors, often involving incremental optical or magnetic sensors connected via multi-pin connectors. Proper mounting of quadrature encoders ensures accurate pulse generation for direction and position tracking, while potentiometers are more susceptible to wear and signal noise without careful mechanical setup.

Advantages and Disadvantages

Potentiometers offer a simple, low-cost solution for analog position sensing with straightforward implementation and easy integration into various circuits, but they suffer from limited lifespan due to mechanical wear and lower resolution. Quadrature encoders provide high precision, digital output ideal for accurate motion control and speed measurement, with robust performance in industrial environments, though they involve higher cost and more complex signal processing. The choice depends on application requirements such as accuracy, durability, and budget constraints.

Choosing the Right Sensor for Your Project

Selecting the right position sensor depends on accuracy, environmental conditions, and application requirements. Potentiometers offer simplicity and cost-effectiveness for low-precision tasks, while quadrature encoders provide high-resolution feedback and durability in dynamic or industrial settings. Evaluating factors like rotational range, output type, and signal processing needs ensures optimal sensor integration.

Potentiometer Infographic

libterm.com

libterm.com