Magnetostrictive materials convert magnetic energy into mechanical strain, making them essential for sensors, actuators, and transducers. Their unique ability to change shape under magnetic fields enables precise control and efficient energy conversion in various industrial applications. Discover how these powerful materials can enhance Your technology and performance in the full article.

Table of Comparison

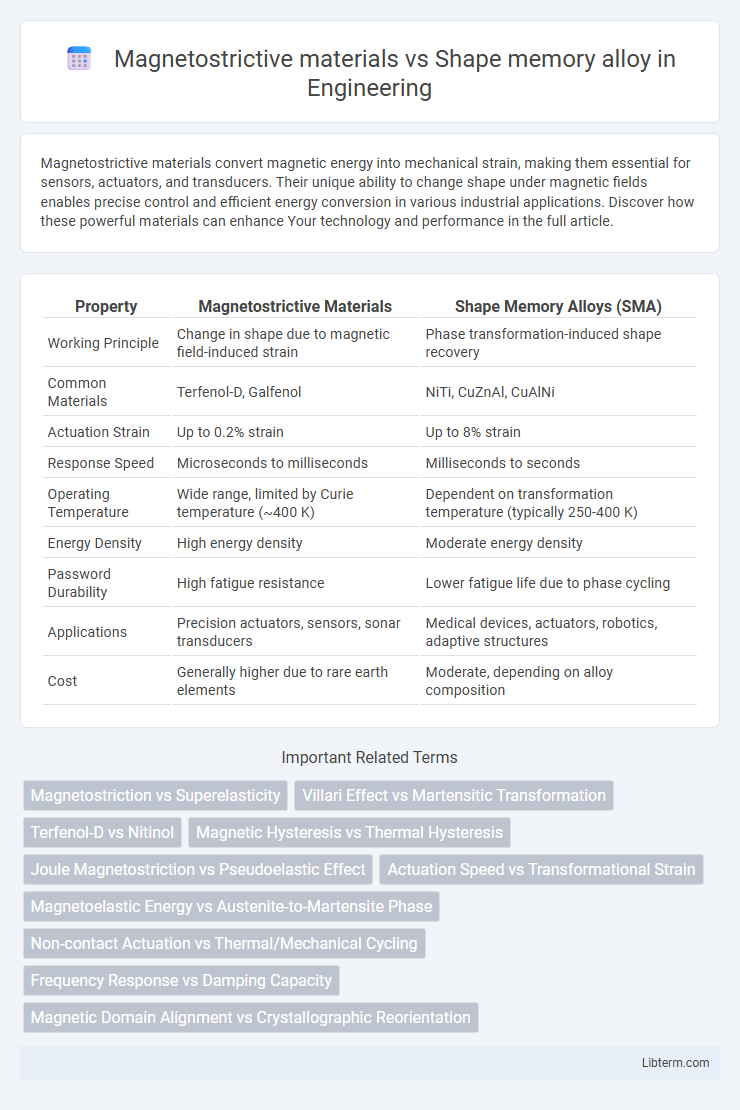

| Property | Magnetostrictive Materials | Shape Memory Alloys (SMA) |

|---|---|---|

| Working Principle | Change in shape due to magnetic field-induced strain | Phase transformation-induced shape recovery |

| Common Materials | Terfenol-D, Galfenol | NiTi, CuZnAl, CuAlNi |

| Actuation Strain | Up to 0.2% strain | Up to 8% strain |

| Response Speed | Microseconds to milliseconds | Milliseconds to seconds |

| Operating Temperature | Wide range, limited by Curie temperature (~400 K) | Dependent on transformation temperature (typically 250-400 K) |

| Energy Density | High energy density | Moderate energy density |

| Password Durability | High fatigue resistance | Lower fatigue life due to phase cycling |

| Applications | Precision actuators, sensors, sonar transducers | Medical devices, actuators, robotics, adaptive structures |

| Cost | Generally higher due to rare earth elements | Moderate, depending on alloy composition |

Introduction to Smart Materials

Smart materials such as magnetostrictive materials and shape memory alloys exhibit unique properties enabling adaptive responses to external stimuli. Magnetostrictive materials change shape or dimensions under magnetic fields, making them ideal for sensors and actuators in precision engineering. Shape memory alloys undergo phase transformations to recover the original shape upon heating, widely used for biomedical devices and actuators requiring high strain recovery.

Fundamentals of Magnetostrictive Materials

Magnetostrictive materials exhibit a change in shape or dimension when exposed to a magnetic field due to the rotation of magnetic domains, enabling precise actuation and sensing applications. These materials rely on the magneto-mechanical coupling effect, where magnetic energy is converted into mechanical strain, distinguishing them from shape memory alloys that undergo phase transformations driven by temperature changes. Key magnetostrictive materials include Terfenol-D and Galfenol, known for their high magnetostriction coefficients and rapid response times.

Shape Memory Alloys: Basic Principles

Shape memory alloys (SMAs) are metallic materials that can recover their original shape after deformation through a thermally induced phase transformation between martensite and austenite phases. The basic principle involves the reversible change in crystal structure, enabling SMAs to exhibit pseudoelasticity and the shape memory effect, which makes them ideal for actuators, sensors, and biomedical devices. Unlike magnetostrictive materials that change shape in response to magnetic fields, SMAs respond primarily to temperature variations, providing distinct advantages in applications requiring high energy density and precise mechanical actuation.

Mechanisms of Actuation: Magnetostriction vs Shape Memory Effect

Magnetostrictive materials actuate by changing shape or dimensions when exposed to a magnetic field due to the realignment of magnetic domains, resulting in strain without phase transformation. Shape memory alloys (SMAs) actuate through a thermoelastic martensitic phase transformation, where heating or cooling induces reversible changes between martensite and austenite phases, causing shape recovery. The magnetostriction mechanism provides rapid response with high-frequency actuation, while the shape memory effect offers larger strain but slower response times due to thermal cycling.

Material Composition and Structure Comparison

Magnetostrictive materials primarily consist of rare earth alloys such as Terfenol-D, composed of terbium, dysprosium, and iron, featuring a highly anisotropic crystal structure that enables dimensional changes under magnetic fields. Shape memory alloys (SMAs) typically include nickel-titanium (Nitinol) or copper-based alloys, characterized by a reversible martensitic phase transformation between austenite and martensite crystal structures, which allows recovery of original shape upon heating. The fundamental difference lies in magneto-mechanical coupling in magnetostrictive materials versus thermally induced phase changes in SMAs, influencing their responsiveness and application domains.

Performance Characteristics and Response Time

Magnetostrictive materials exhibit high-frequency response and exceptional precision in actuation due to their rapid strain response to magnetic fields, typically in the microsecond range, making them ideal for dynamic applications requiring fast and repeatable movements. Shape memory alloys (SMAs) have slower response times, often in the range of milliseconds to seconds, because their actuation relies on thermally induced phase transformations, resulting in higher actuation strain but limited cycling frequency and slower recovery. Performance-wise, magnetostrictive materials provide superior stiffness and force density with low hysteresis, while SMAs deliver larger strains with lower force output but suffer from fatigue and slower response.

Key Applications in Modern Technology

Magnetostrictive materials are primarily used in precision sensors, actuators, and energy harvesting devices due to their ability to convert magnetic energy into mechanical strain with high sensitivity and frequency response. Shape memory alloys find key applications in biomedical devices, aerospace actuators, and robotics, leveraging their unique capability to recover pre-defined shapes upon heating. Both materials drive innovations in smart structures, with magnetostrictive materials excelling in real-time vibration control and shape memory alloys enhancing adaptive and self-healing systems.

Advantages and Limitations of Each Material

Magnetostrictive materials offer rapid response times and high energy density, making them ideal for precise actuation in sensors and actuators; however, they often require strong magnetic fields and can suffer from temperature sensitivity. Shape memory alloys provide large, recoverable strains and noise-free operation, advantageous for applications requiring significant deformation, but their slower response and limited fatigue life restrict long-term use. Both materials exhibit unique benefits and drawbacks that influence their suitability across different fields such as robotics, aerospace, and medical devices.

Recent Innovations and Research Trends

Recent innovations in magnetostrictive materials emphasize enhanced energy conversion efficiency and tunable strain responses through nano-engineering and alloying techniques, leading to improved actuator and sensor applications. Shape memory alloys exhibit advancements in fatigue resistance and thermal stability owing to novel compositional designs and additive manufacturing processes, enabling broader use in aerospace and biomedical fields. Research trends highlight the integration of both materials in hybrid systems to exploit magnetostrictive precision and shape memory adaptability for next-generation smart devices.

Future Prospects and Industry Outlook

Magnetostrictive materials are poised for significant growth in precision sensing and actuation applications due to their fast response times and high energy density. Shape memory alloys continue to advance in biomedical and aerospace sectors, leveraging their unique phase transformation properties for adaptive structures and minimally invasive devices. Emerging research aims to integrate both materials into hybrid systems, enhancing multifunctionality and expanding industrial applications in robotics and smart infrastructure.

Magnetostrictive materials Infographic

libterm.com

libterm.com