A solid slab is a common structural element in construction, known for its durability and ability to bear heavy loads. It consists of a thick, continuous layer of reinforced concrete that provides a stable base for floors or roofs. Explore the rest of the article to understand how solid slabs benefit your building projects.

Table of Comparison

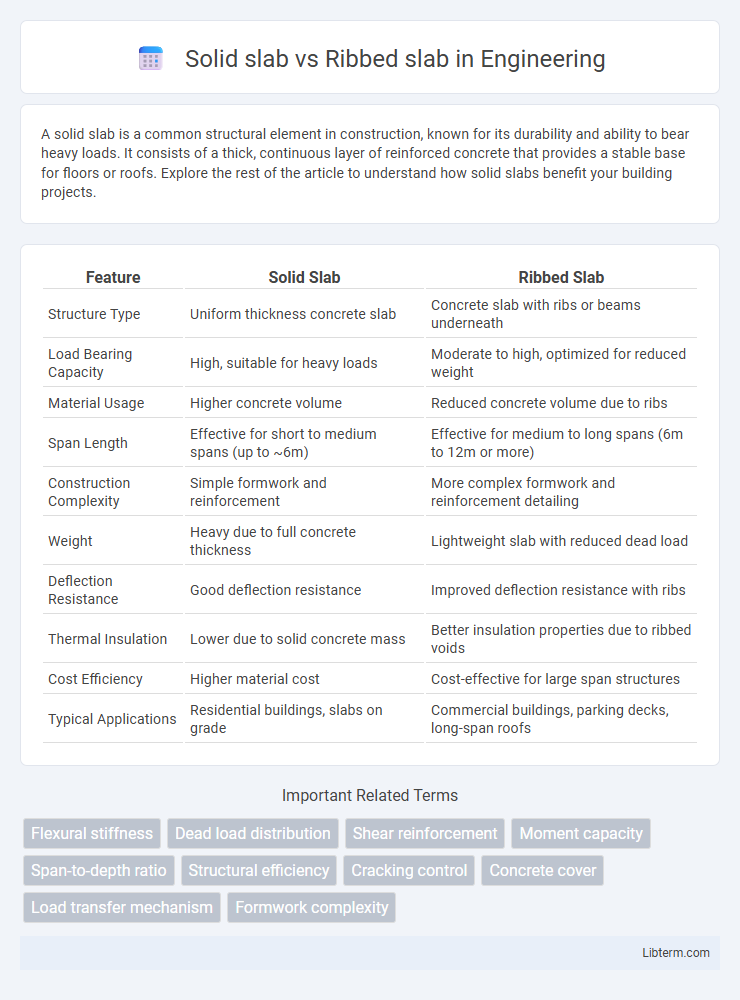

| Feature | Solid Slab | Ribbed Slab |

|---|---|---|

| Structure Type | Uniform thickness concrete slab | Concrete slab with ribs or beams underneath |

| Load Bearing Capacity | High, suitable for heavy loads | Moderate to high, optimized for reduced weight |

| Material Usage | Higher concrete volume | Reduced concrete volume due to ribs |

| Span Length | Effective for short to medium spans (up to ~6m) | Effective for medium to long spans (6m to 12m or more) |

| Construction Complexity | Simple formwork and reinforcement | More complex formwork and reinforcement detailing |

| Weight | Heavy due to full concrete thickness | Lightweight slab with reduced dead load |

| Deflection Resistance | Good deflection resistance | Improved deflection resistance with ribs |

| Thermal Insulation | Lower due to solid concrete mass | Better insulation properties due to ribbed voids |

| Cost Efficiency | Higher material cost | Cost-effective for large span structures |

| Typical Applications | Residential buildings, slabs on grade | Commercial buildings, parking decks, long-span roofs |

Introduction to Solid Slab and Ribbed Slab Systems

Solid slabs are flat, uniform concrete slabs commonly used in residential and commercial buildings for their simplicity and load-bearing capacity. Ribbed slabs incorporate a grid of ribs or beams beneath the slab surface, reducing weight and material usage while maintaining structural strength. The choice between solid and ribbed slabs depends on factors such as span length, load requirements, and construction cost efficiency.

Structural Composition: Solid vs. Ribbed Slabs

Solid slabs consist of a uniform thickness of concrete reinforced with steel bars throughout, providing a continuous load-bearing surface ideal for short spans and heavy loads. Ribbed slabs feature a series of parallel beams or ribs beneath a thin concrete slab, optimizing material usage by reducing weight and enhancing structural efficiency for longer spans. The choice between solid and ribbed slabs depends on load requirements, span length, and construction economy, with ribbed slabs offering improved bending resistance and reduced dead load.

Load Bearing Capacity Comparison

Solid slabs provide uniform load distribution and higher load-bearing capacity for heavy and concentrated loads due to their continuous cross-section. Ribbed slabs feature ribs that reduce self-weight and material usage but offer lower load-bearing capacity compared to solid slabs, making them suitable for moderate loads and longer spans. Structural engineers select slab types based on load demands, span lengths, and cost efficiency to optimize performance and material usage.

Material Efficiency and Cost Considerations

Ribbed slabs use less concrete and steel reinforcement compared to solid slabs, resulting in improved material efficiency and reduced overall weight. The voids in ribbed slabs decrease dead load, leading to lower foundation costs and faster construction times. While ribbed slabs may require higher initial formwork and labor expenses, their long-term cost benefits include savings on materials and enhanced structural performance.

Construction Methods and Speed

Solid slabs involve pouring concrete over a continuous framework supported by formwork and scaffolding, resulting in a straightforward construction process but requiring more material and longer curing times. Ribbed slabs utilize precast or cast-in-place ribs with a thinner slab on top, reducing concrete volume and weight, which accelerates construction speed due to less formwork and faster load-bearing capacity. The choice between solid and ribbed slabs significantly impacts overall project timelines, where ribbed slabs offer faster assembly and reduced labor costs in large-span structures.

Application Suitability and Typical Uses

Solid slabs are ideal for residential buildings and small-scale structures due to their uniform thickness, simplicity, and ability to support moderate loads efficiently. Ribbed slabs offer enhanced strength-to-weight ratios, making them suitable for large-span industrial buildings, parking garages, and commercial spaces where reduced dead load and increased structural depth are critical. Selecting between solid and ribbed slabs depends on factors such as load requirements, span length, construction speed, and architectural considerations.

Flexibility in Design and Architectural Implications

Ribbed slabs offer greater flexibility in design by allowing longer spans and customized beam spacing, which supports varied architectural layouts and reduces material usage. Solid slabs, while simpler and more uniform, limit design adaptability due to consistent thickness and higher self-weight, impacting the potential for open floor plans. This structural distinction directly influences architectural creativity and efficient space utilization in building projects.

Thermal and Acoustic Performance

Solid slabs offer superior thermal insulation due to their uniform mass, which helps in maintaining consistent indoor temperatures and reducing energy consumption. Ribbed slabs, with their hollow sections, typically provide better acoustic performance by disrupting sound transmission and reducing noise levels between floors. The choice between solid and ribbed slabs should consider the balance between thermal retention needs and soundproofing requirements in building design.

Maintenance and Durability Insights

Solid slabs offer consistent durability with low maintenance needs due to their uniform thickness and absence of voids, reducing the risk of cracks and water infiltration. Ribbed slabs, while lighter and cost-effective, require regular inspection and upkeep to address potential issues in the ribs and voids that may compromise structural integrity over time. Maintenance efforts for ribbed slabs typically involve monitoring for corrosion in reinforcement and ensuring proper waterproofing to enhance lifespan.

Conclusion: Choosing the Right Slab System

Solid slabs provide uniform strength and simplicity for short spans and heavier loads, making them ideal for residential buildings and small commercial projects. Ribbed slabs offer material efficiency and reduced weight suitable for longer spans and structures requiring flexibility, such as large commercial or industrial buildings. Selecting between solid and ribbed slabs depends on project-specific factors like load requirements, span length, budget constraints, and construction time.

Solid slab Infographic

libterm.com

libterm.com