Actuator displacement refers to the linear or angular movement produced by an actuator in response to an input signal, playing a crucial role in precision control systems. Understanding actuator displacement helps optimize performance in applications ranging from robotics to industrial automation, ensuring accurate positioning and efficient operation. Explore the rest of this article to gain insights on measuring and improving your actuator displacement for enhanced device functionality.

Table of Comparison

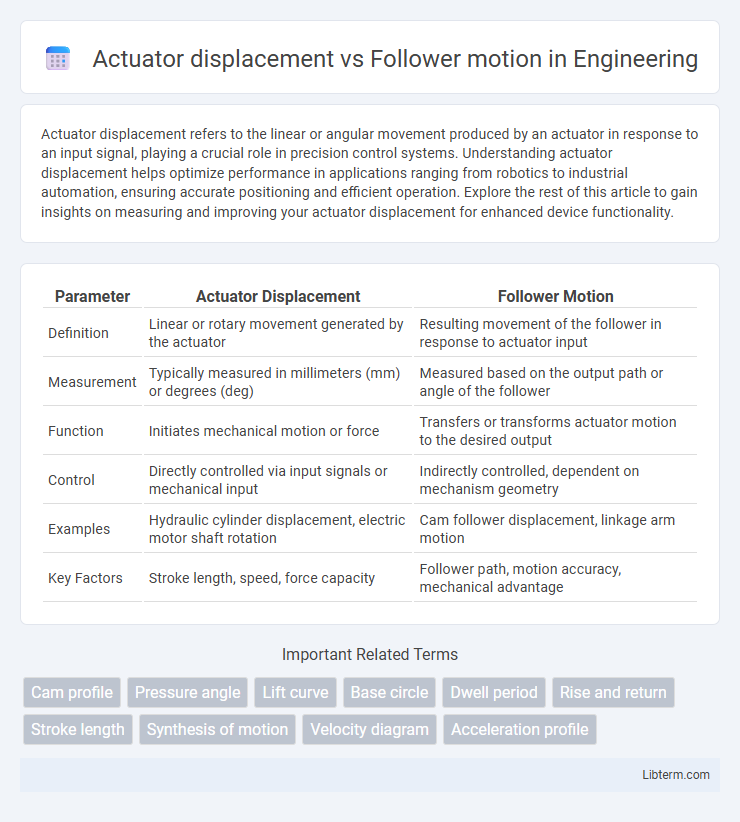

| Parameter | Actuator Displacement | Follower Motion |

|---|---|---|

| Definition | Linear or rotary movement generated by the actuator | Resulting movement of the follower in response to actuator input |

| Measurement | Typically measured in millimeters (mm) or degrees (deg) | Measured based on the output path or angle of the follower |

| Function | Initiates mechanical motion or force | Transfers or transforms actuator motion to the desired output |

| Control | Directly controlled via input signals or mechanical input | Indirectly controlled, dependent on mechanism geometry |

| Examples | Hydraulic cylinder displacement, electric motor shaft rotation | Cam follower displacement, linkage arm motion |

| Key Factors | Stroke length, speed, force capacity | Follower path, motion accuracy, mechanical advantage |

Introduction to Actuators and Followers

Actuator displacement refers to the specific movement or stroke length produced by an actuator when converting energy into mechanical motion. Follower motion describes how this actuator displacement translates into the movement of a follower, which can exhibit different types of motion such as oscillating, reciprocating, or uniform depending on the mechanism design. Understanding the precise relationship between actuator displacement and follower motion is crucial for designing efficient mechanical systems in automation, robotics, and engine valve operations.

Defining Actuator Displacement

Actuator displacement refers to the linear or angular movement produced by an actuator in response to an input signal, often measured in millimeters or degrees. It serves as the primary input controlling the follower motion, which is the resulting movement or position change of a mechanical follower in a system. Precise control of actuator displacement is crucial for accurate prediction and synchronization of follower trajectories in automation and robotics applications.

Understanding Follower Motion

Follower motion in mechanical systems is characterized by the precise response of the follower to the actuator displacement, determining the output motion pattern such as oscillation, uniform motion, or dwell periods. Understanding this relationship involves analyzing parameters like displacement amplitude, velocity profile, and acceleration to evaluate the dynamic behavior of the follower. Accurate modeling of actuator displacement is essential for predicting follower motion in applications like cam-follower mechanisms, robotic arms, and automated machinery.

Key Differences Between Actuator Displacement and Follower Motion

Actuator displacement refers to the linear or angular movement generated by an actuator as it converts energy into mechanical motion, while follower motion describes the trajectory or path traced by the follower element in a mechanism. The primary difference lies in actuator displacement being the input movement provided by a power source, whereas follower motion is the output response influenced by the mechanism's geometry and constraints. Actuator displacement is typically controlled and measurable, whereas follower motion can be complex, including varying velocity profiles and directions dependent on the cam or linkage design.

Relationship Between Actuator Displacement and Follower Response

The relationship between actuator displacement and follower motion is fundamentally defined by the mechanical linkages or cam profiles translating input movement into output response. Actuator displacement directly influences the amplitude and velocity of the follower's motion, determining precision and accuracy in mechanical systems such as engines or automation equipment. Understanding this correlation is critical for optimizing dynamic performance and ensuring the synchronization of motion in control mechanisms.

Types of Actuators and Their Motion Profiles

Actuator displacement and follower motion vary significantly based on actuator type, with linear actuators providing straightforward linear displacement ideal for precise follower movements in automation. Rotary actuators convert input signals into rotational displacement, producing circular follower motion essential in applications like valve control and robotics. Piezoelectric actuators exhibit high-frequency, small-amplitude displacement, enabling ultra-precise follower motion in micro-positioning systems.

Common Follower Mechanisms in Mechanical Systems

Common follower mechanisms in mechanical systems, such as cam-follower, crank-slider, and lever mechanisms, directly translate actuator displacement into precise follower motion. The relationship between actuator displacement and follower movement is critical for achieving desired motion profiles, where cam profiles are designed to convert rotary actuator displacement into linear or oscillatory follower motion. Accurate modeling of these mechanisms ensures efficient energy transfer and predictable dynamic response in applications ranging from automotive engines to automation equipment.

Factors Affecting Follower Motion

Actuator displacement directly influences follower motion by determining the precise position and velocity of the follower in mechanical systems such as cam-follower mechanisms. Factors affecting follower motion include the actuator's design parameters like stroke length, input force, and motion profile, as well as system dynamics such as friction, inertia, and backlash. Material properties and lubrication also play a critical role in minimizing wear and ensuring smooth, accurate follower response to actuator displacement.

Practical Applications: Matching Displacement to Follower Needs

Actuator displacement must precisely align with the required follower motion to ensure efficient energy transfer and optimal mechanical performance in applications such as automotive valve actuation and robotic arms. Selecting actuators with displacement ranges tailored to follower kinematics enhances durability and reduces wear by preventing overextension or insufficient movement. In manufacturing automation, fine-tuning this relationship improves process accuracy, speed, and overall system reliability.

Optimizing System Performance: Design Tips and Best Practices

Optimizing actuator displacement relative to follower motion requires precise calibration to minimize mechanical losses and enhance response accuracy in dynamic systems. Selecting actuators with appropriate stroke lengths and integrating real-time feedback sensors improve motion synchronization, reducing backlash and hysteresis effects. Implementing advanced control algorithms and high-quality materials in mechanical linkages ensures consistent performance and maximizes energy efficiency in precision applications.

Actuator displacement Infographic

libterm.com

libterm.com