Surface finish impacts the functionality and appearance of manufactured parts by affecting friction, wear resistance, and corrosion protection. Achieving the right surface finish enhances your product's performance and durability while also improving aesthetic appeal. Explore the rest of the article to learn how to optimize surface finish for your specific applications.

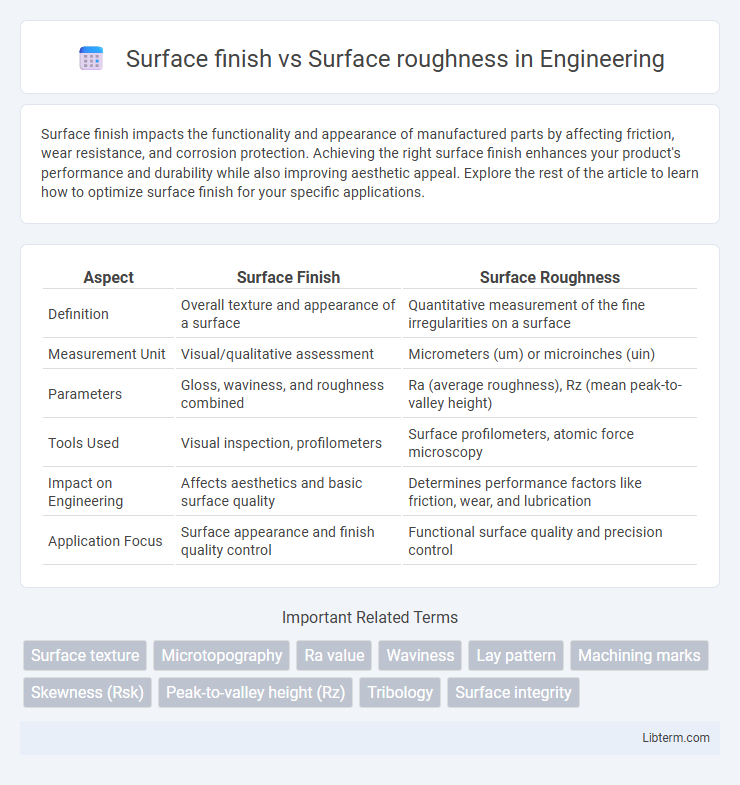

Table of Comparison

| Aspect | Surface Finish | Surface Roughness |

|---|---|---|

| Definition | Overall texture and appearance of a surface | Quantitative measurement of the fine irregularities on a surface |

| Measurement Unit | Visual/qualitative assessment | Micrometers (um) or microinches (uin) |

| Parameters | Gloss, waviness, and roughness combined | Ra (average roughness), Rz (mean peak-to-valley height) |

| Tools Used | Visual inspection, profilometers | Surface profilometers, atomic force microscopy |

| Impact on Engineering | Affects aesthetics and basic surface quality | Determines performance factors like friction, wear, and lubrication |

| Application Focus | Surface appearance and finish quality control | Functional surface quality and precision control |

Introduction to Surface Finish and Surface Roughness

Surface finish refers to the overall texture and quality of a machined or manufactured surface, encompassing characteristics such as waviness, roughness, and lay patterns. Surface roughness specifically quantifies the fine irregularities and deviations on the surface, often measured using parameters like Ra (average roughness) and Rz (maximum height). Understanding the distinctions between surface finish and surface roughness is critical for optimizing product performance, wear resistance, and aesthetic appeal in engineering and manufacturing processes.

Defining Surface Finish: Key Concepts

Surface finish defines the overall texture quality of a material's surface, encompassing factors such as lay, waviness, and surface roughness. Surface roughness specifically measures the fine irregularities and deviations from the nominal surface, typically quantified by parameters like Ra (average roughness) and Rz (average peak-to-valley height). Understanding the distinction between surface finish and surface roughness is critical for applications requiring precise control of friction, wear, and aesthetic appearance in manufacturing and material engineering.

Understanding Surface Roughness: Parameters and Measurements

Surface roughness represents the quantitative measurement of surface texture, typically defined by parameters such as Ra (average roughness), Rz (mean peak-to-valley height), and Rq (root mean square roughness). These parameters are measured using profilometers or atomic force microscopes, which provide detailed information about surface deviations at micro and nano scales. Understanding surface roughness is crucial for predicting material performance in applications where contact, friction, and wear are factors, differentiating it from surface finish, which broadly refers to the overall appearance and quality of the surface.

Differences Between Surface Finish and Surface Roughness

Surface finish refers to the overall texture and visual appearance of a surface, encompassing factors like waviness, lay, and roughness, while surface roughness specifically measures the fine irregularities on the surface at a microscopic level. Surface finish is a broader term that includes surface roughness as one of its components, representing the surface quality perceived visually and tactilely. Measurements of surface roughness are typically quantified using parameters such as Ra (average roughness) or Rz (mean peak-to-valley height), whereas surface finish assessment involves qualitative evaluation and may incorporate both roughness and waviness characteristics.

Importance of Surface Texture in Manufacturing

Surface finish and surface roughness critically influence the performance and longevity of manufactured components by affecting friction, wear resistance, and fatigue strength. Precise control over surface texture ensures optimal fit, sealing, and aesthetic quality, directly impacting product reliability and cost efficiency. Advanced manufacturing processes utilize surface finish measurements to maintain stringent quality standards and enhance overall functionality.

Common Methods for Measuring Surface Finish

Common methods for measuring surface finish include contact profilometry, using a stylus to trace surface texture and quantify roughness parameters such as Ra and Rz. Non-contact techniques like laser scanning and white light interferometry provide high-resolution 3D surface characterization without damaging delicate materials. Optical microscopy and atomic force microscopy (AFM) offer detailed surface topography analysis, essential for industries requiring precise surface quality control.

Factors Affecting Surface Roughness in Machining

Surface roughness in machining is influenced by cutting parameters such as feed rate, cutting speed, and depth of cut, where higher feed rates typically increase roughness. Tool geometry, including the tool nose radius and wear condition, plays a critical role in determining surface texture quality. Material properties and machine tool vibrations also significantly affect the final surface roughness, distinguishing it from the general concept of surface finish.

Impacts of Surface Quality on Product Performance

Surface finish and surface roughness critically influence product performance by affecting friction, wear resistance, and fatigue life. A smoother surface finish typically reduces friction and enhances corrosion resistance, leading to longer-lasting components in aerospace and automotive industries. Precise control of surface roughness ensures reliable sealing interfaces and improves the efficiency of mechanical systems by minimizing energy loss and preventing premature failures.

Applications Requiring Precise Surface Specifications

Surface finish and surface roughness are critical parameters in applications requiring precise surface specifications, such as aerospace, automotive, and medical device manufacturing. Surface finish encompasses the overall texture, including lay, waviness, and roughness, while surface roughness specifically quantifies small-scale irregularities using measurements like Ra (average roughness) and Rz (mean peak-to-valley height). Precise control of surface roughness directly impacts component performance, wear resistance, and sealing capabilities, making it essential for high-precision engineering and quality assurance in advanced manufacturing processes.

Best Practices for Achieving Desired Surface Characteristics

Surface finish and surface roughness are critical parameters in manufacturing that influence product performance and aesthetics. Best practices for achieving desired surface characteristics include selecting appropriate machining processes, utilizing precision tooling, and implementing controlled cutting conditions to minimize irregularities. Consistent measurement using profilometers and adhering to industry standards such as ISO 4287 ensure repeatability and optimal surface quality.

Surface finish Infographic

libterm.com

libterm.com