Vibration damping reduces unwanted oscillations in mechanical systems, improving stability and extending equipment lifespan. Effective damping materials and techniques absorb energy, minimizing noise and preventing structural damage. Discover how optimizing vibration damping can enhance Your system's performance throughout the rest of this article.

Table of Comparison

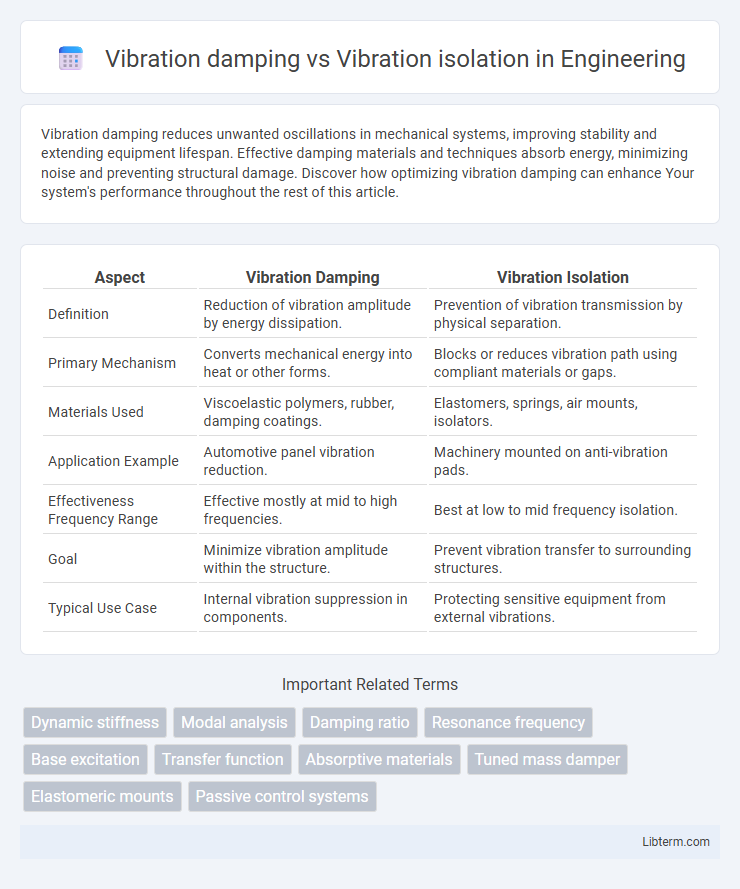

| Aspect | Vibration Damping | Vibration Isolation |

|---|---|---|

| Definition | Reduction of vibration amplitude by energy dissipation. | Prevention of vibration transmission by physical separation. |

| Primary Mechanism | Converts mechanical energy into heat or other forms. | Blocks or reduces vibration path using compliant materials or gaps. |

| Materials Used | Viscoelastic polymers, rubber, damping coatings. | Elastomers, springs, air mounts, isolators. |

| Application Example | Automotive panel vibration reduction. | Machinery mounted on anti-vibration pads. |

| Effectiveness Frequency Range | Effective mostly at mid to high frequencies. | Best at low to mid frequency isolation. |

| Goal | Minimize vibration amplitude within the structure. | Prevent vibration transfer to surrounding structures. |

| Typical Use Case | Internal vibration suppression in components. | Protecting sensitive equipment from external vibrations. |

Introduction to Vibration Damping and Isolation

Vibration damping reduces the amplitude of vibrations by converting kinetic energy into heat or other forms of energy within a material, enhancing the durability and performance of mechanical systems. Vibration isolation, on the other hand, prevents the transmission of vibrations from a source to surrounding structures using devices such as springs, mounts, or pads to minimize impact. Both techniques are essential in engineering to control unwanted vibrations, improve comfort, and protect sensitive equipment in industries ranging from automotive to aerospace.

Defining Vibration Damping

Vibration damping refers to the process of reducing the amplitude of vibrations by converting vibrational energy into heat or other forms of energy, typically through materials like viscoelastic polymers or mechanical dampers. Unlike vibration isolation, which aims to prevent the transmission of vibrations from one structure to another using mounts or pads, vibration damping directly decreases the vibrational energy within a system. Effective vibration damping improves the longevity and performance of machinery by minimizing resonant frequencies and mechanical wear.

Understanding Vibration Isolation

Vibration isolation involves reducing the transmission of vibrations from a source to a sensitive structure by using materials or devices that absorb or deflect vibrational energy, such as isolators, mounts, or pads. It prevents vibrations from propagating and affecting equipment accuracy or structural integrity, making it critical in precision machinery and building foundations. Effective vibration isolation minimizes resonance and noise, enhancing performance and extending the lifespan of mechanical systems.

Key Differences Between Damping and Isolation

Vibration damping reduces the amplitude of vibrations by converting mechanical energy into heat through materials like viscoelastic polymers, while vibration isolation prevents the transmission of vibrations to sensitive equipment by introducing barriers such as springs or rubber mounts. Damping typically occurs within the vibrating system itself to control resonance and oscillations, whereas isolation focuses on decoupling the source of vibration from the protected structure. The key difference lies in damping's energy dissipation versus isolation's energy redirection or blocking to minimize vibrational impact.

Common Applications of Vibration Damping

Vibration damping is widely used in automotive suspensions, industrial machinery, and building structures to reduce resonance and minimize noise by dissipating vibrational energy. Common applications include damping materials in engine mounts, vibration-absorbing pads under heavy equipment, and viscoelastic layers in aerospace components. These damping solutions enhance performance, prolong equipment life, and improve comfort in transportation and manufacturing environments.

Common Uses of Vibration Isolation

Vibration isolation is commonly used in manufacturing equipment, HVAC systems, and building foundations to prevent the transmission of unwanted vibrations, protecting sensitive machinery and enhancing structural integrity. Unlike vibration damping, which reduces vibration energy within a system, vibration isolation physically separates the source of vibration from the affected area, effectively minimizing noise and mechanical wear. Its application in precision instruments, electronic devices, and automotive components ensures improved performance and longevity by reducing vibration-induced disturbances.

Materials and Technologies for Damping

Vibration damping involves the use of viscoelastic materials such as rubber, polyurethane, and specialized damping polymers that convert vibrational energy into heat, reducing amplitude within structures. Vibration isolation employs materials like elastomeric mounts, springs, and air bladders designed to physically separate equipment from vibration sources, minimizing transmission. Advanced technologies in damping incorporate nano-engineered composites and magnetorheological fluids which adapt their properties dynamically to optimize energy dissipation across varying frequencies.

Isolation Devices and Solutions

Vibration isolation devices, such as elastomer mounts, spring isolators, and pneumatic isolators, are designed to reduce the transmission of vibrations from a source to surrounding structures by creating a physical barrier or suspension system. These solutions effectively decouple machinery or equipment from floors and foundations, minimizing noise and structural fatigue. Vibration damping, by contrast, typically involves materials or coatings like viscoelastic polymers that absorb and dissipate vibrational energy within the equipment itself, making isolation devices the preferred choice for preventing vibration propagation and protecting sensitive components.

Selecting the Right Method: Factors to Consider

Selecting the right method between vibration damping and vibration isolation depends on factors like the frequency and amplitude of vibrations, system sensitivity, and environmental conditions. Vibration damping is suitable for reducing amplitude within a system by converting kinetic energy into heat, ideal for high-frequency, low-amplitude vibrations. Vibration isolation excels in preventing vibration transmission to or from equipment, making it essential for low-frequency, high-amplitude disturbances and protecting sensitive machinery.

Summary: Damping vs Isolation in Practice

Vibration damping reduces the amplitude of vibrations by converting mechanical energy into heat, effectively controlling resonance and improving system stability. Vibration isolation prevents vibration transmission by physically decoupling the source from sensitive components using materials or mounts that absorb or block vibrational energy. In practice, damping is used to manage vibrations within structures, while isolation is critical for protecting delicate equipment from external vibration sources.

Vibration damping Infographic

libterm.com

libterm.com