Cavitation peening enhances metal durability by using high-energy shock waves created from collapsing bubbles to relieve surface stress and improve fatigue resistance. This process effectively reduces cracks and extends the lifespan of components without causing thermal damage. Discover how cavitation peening can transform Your manufacturing and maintenance strategies in the full article.

Table of Comparison

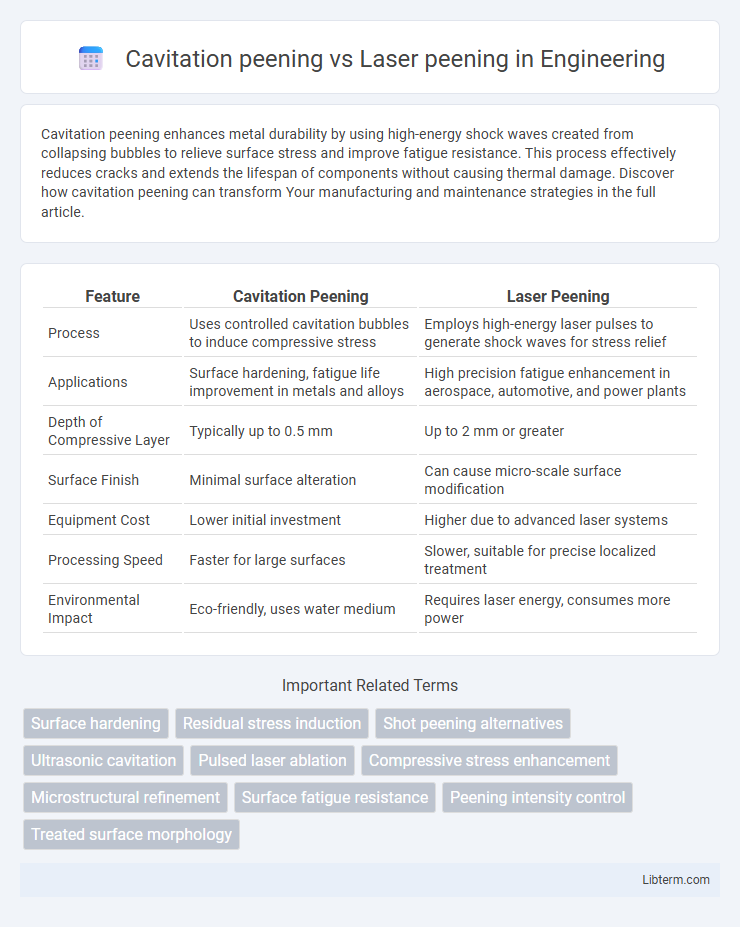

| Feature | Cavitation Peening | Laser Peening |

|---|---|---|

| Process | Uses controlled cavitation bubbles to induce compressive stress | Employs high-energy laser pulses to generate shock waves for stress relief |

| Applications | Surface hardening, fatigue life improvement in metals and alloys | High precision fatigue enhancement in aerospace, automotive, and power plants |

| Depth of Compressive Layer | Typically up to 0.5 mm | Up to 2 mm or greater |

| Surface Finish | Minimal surface alteration | Can cause micro-scale surface modification |

| Equipment Cost | Lower initial investment | Higher due to advanced laser systems |

| Processing Speed | Faster for large surfaces | Slower, suitable for precise localized treatment |

| Environmental Impact | Eco-friendly, uses water medium | Requires laser energy, consumes more power |

Introduction to Cavitation Peening and Laser Peening

Cavitation peening utilizes high-pressure shockwaves from imploding bubbles to induce plastic deformation and improve surface hardness, making it effective for reducing residual tensile stresses and enhancing fatigue life. Laser peening employs high-energy laser pulses to generate shockwaves in metal surfaces, producing deep compressive residual stresses and superior resistance to crack initiation and propagation. Both techniques are advanced surface treatment methods used to extend component lifespan in aerospace, automotive, and power generation industries.

Fundamental Principles of Cavitation Peening

Cavitation peening relies on the generation and collapse of vapor bubbles in a liquid medium, producing high-pressure shock waves that induce plastic deformation and residual compressive stress on metal surfaces. This process enhances fatigue strength, corrosion resistance, and surface hardness by modifying the microstructure through localized mechanical impacts. Unlike laser peening, which uses high-energy laser pulses to create shock waves, cavitation peening employs hydrodynamic phenomena, making it suitable for complex geometries and sensitive materials.

Understanding the Laser Peening Process

Laser peening uses high-energy laser pulses to generate shock waves on the material surface, inducing deep compressive residual stresses that improve fatigue life and resistance to stress corrosion cracking. Unlike cavitation peening, which relies on collapsing bubbles to create surface impacts, laser peening offers precise control over stress depth and intensity, enabling tailored surface enhancements. This process is widely applied in aerospace and automotive industries for critical components requiring enhanced durability and performance.

Key Differences Between Cavitation and Laser Peening

Cavitation peening utilizes high-pressure water jets to induce cavitation bubbles that implode and create compressive stresses on the material surface, enhancing fatigue resistance and corrosion resistance. Laser peening employs high-energy laser pulses to generate shock waves, resulting in deeper and more uniform residual compressive stresses that improve crack propagation resistance and mechanical strength. Key differences include energy source types, depth of compressive stress layers, and suitability for complex geometries, with laser peening offering greater precision and penetration but higher operational costs compared to cavitation peening.

Comparative Surface Modification Effects

Cavitation peening generates compressive residual stresses by inducing microjet impacts and shockwaves from collapsing bubbles, effectively improving surface hardness and fatigue resistance in metals. Laser peening, using high-energy laser pulses, produces deeper compressive stress layers and enhances surface integrity with minimal thermal effects, making it preferable for critical aerospace and automotive components. Compared to cavitation peening, laser peening achieves superior depth of modification and increased resistance to stress corrosion cracking while cavitation peening offers cost-effective treatment for complex geometries.

Applications in Aerospace and Automotive Industries

Cavitation peening enhances fatigue resistance and stress corrosion cracking prevention in aerospace components like turbine blades and aircraft frames by utilizing bubble collapse-induced shock waves. Laser peening offers deeper residual stress penetration ideal for automotive engine parts and structural aerospace elements, improving crack initiation delay and extending service life under cyclic loading. Both techniques optimize surface durability and performance, with cavitation peening favored for complex geometries and laser peening suited for precision-treated critical components.

Advantages of Cavitation Peening

Cavitation peening offers significant advantages over laser peening by providing a more cost-effective and environmentally friendly surface treatment process with lower equipment and operational expenses. This technique induces compressive residual stresses through controlled bubble collapses, enhancing fatigue strength and corrosion resistance without the high thermal impact associated with laser peening. Its ability to uniformly treat complex geometries and inaccessible areas makes cavitation peening highly versatile for improving material durability in automotive, aerospace, and marine industries.

Benefits of Laser Peening

Laser peening offers superior surface strengthening by inducing deep compressive residual stresses, significantly enhancing fatigue life and resistance to stress corrosion cracking compared to cavitation peening. This method provides precise control over the treatment area and depth, resulting in uniform and reproducible mechanical improvements on complex geometries. Furthermore, laser peening's non-contact process minimizes surface contamination and damage, making it ideal for high-performance aerospace and automotive components.

Challenges and Limitations of Each Technique

Cavitation peening faces challenges such as limited control over intensity and depth due to the random nature of bubble collapse, leading to inconsistent surface enhancement and potential surface damage. Laser peening is limited by high equipment costs and complex setup requirements, alongside challenges in treating complex geometries and potential thermal effects on the material. Both techniques require careful process optimization to avoid adverse effects like residual stress imbalance or surface cracking.

Future Trends in Peening Technologies

Cavitation peening and laser peening represent cutting-edge surface enhancement techniques, with future trends emphasizing increased automation and integration with Industry 4.0 technologies for real-time monitoring and control. Advancements in laser peening focus on higher precision and energy efficiency, while cavitation peening is evolving towards scalable, eco-friendly processes using ultrasonic and hydrodynamic methods. Both technologies are expected to benefit from AI-driven optimization to enhance fatigue resistance and extend component lifespans in aerospace and automotive industries.

Cavitation peening Infographic

libterm.com

libterm.com