Injection molding is a highly efficient manufacturing process used to produce complex plastic parts with precision and repeatability. This technique involves injecting molten material into a mold cavity, where it cools and solidifies into the desired shape, making it ideal for mass production. Discover how injection molding can enhance your manufacturing capabilities by reading the full article.

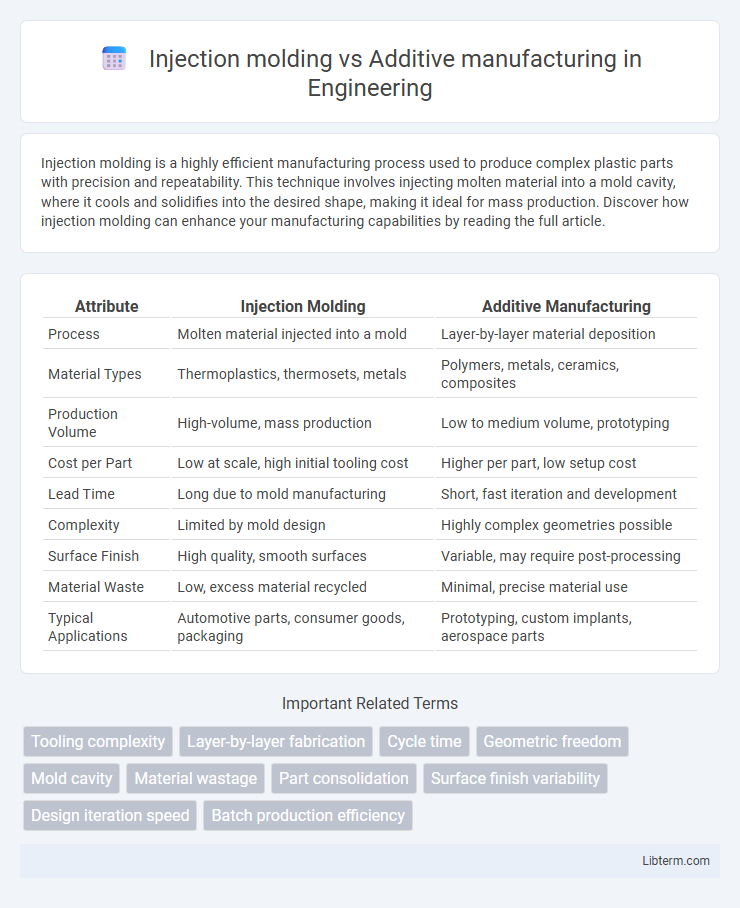

Table of Comparison

| Attribute | Injection Molding | Additive Manufacturing |

|---|---|---|

| Process | Molten material injected into a mold | Layer-by-layer material deposition |

| Material Types | Thermoplastics, thermosets, metals | Polymers, metals, ceramics, composites |

| Production Volume | High-volume, mass production | Low to medium volume, prototyping |

| Cost per Part | Low at scale, high initial tooling cost | Higher per part, low setup cost |

| Lead Time | Long due to mold manufacturing | Short, fast iteration and development |

| Complexity | Limited by mold design | Highly complex geometries possible |

| Surface Finish | High quality, smooth surfaces | Variable, may require post-processing |

| Material Waste | Low, excess material recycled | Minimal, precise material use |

| Typical Applications | Automotive parts, consumer goods, packaging | Prototyping, custom implants, aerospace parts |

Introduction to Injection Molding and Additive Manufacturing

Injection molding is a manufacturing process that forces molten material, typically plastic, into a mold cavity to produce high-precision, repeatable parts in large volumes. Additive manufacturing, or 3D printing, builds objects layer by layer directly from digital models, offering superior flexibility for complex geometries and rapid prototyping. Both methods serve distinct production needs, with injection molding optimized for mass production and additive manufacturing excelling in customization and low-volume runs.

Core Principles and Processes

Injection molding involves injecting molten material, typically thermoplastic or thermosetting polymers, into a metal mold cavity under high pressure to produce precise, repeatable parts with high production rates. Additive manufacturing builds objects layer-by-layer directly from 3D digital models using processes such as fused deposition modeling (FDM), stereolithography (SLA), or selective laser sintering (SLS), allowing for complex geometries and rapid prototyping. While injection molding relies on subtractive mold fabrication and high-volume production, additive manufacturing emphasizes versatility, customization, and minimal tooling requirements.

Material Compatibility and Selection

Injection molding supports a wide range of thermoplastics such as ABS, polypropylene, and polycarbonate, offering consistent material properties and high production volumes. Additive manufacturing excels in processing complex geometries with materials like photopolymers, nylon, and metals including titanium and stainless steel, with enhanced flexibility in custom material blends. Material selection in injection molding prioritizes uniformity and durability for mass production, while additive manufacturing enables rapid prototyping and customized material properties for specialized applications.

Design Flexibility and Complexity

Injection molding excels in high-volume production but is limited by rigid mold designs, restricting the creation of highly intricate or customized parts. Additive manufacturing offers superior design flexibility, enabling the fabrication of complex geometries, internal channels, and custom features without additional tooling costs. This makes additive manufacturing ideal for prototyping and low-volume, highly detailed components that are unattainable with traditional injection molding.

Production Speed and Lead Times

Injection molding offers significantly faster production speeds and shorter lead times for high-volume manufacturing due to its ability to produce thousands of identical parts rapidly after initial mold creation. Additive manufacturing, while slower per part, excels in rapid prototyping and low-volume production by eliminating tooling requirements and reducing design-to-part time. For mass production, injection molding remains optimal, whereas additive manufacturing provides speed advantages in customized or complex components with shorter setup durations.

Cost Analysis: Prototyping and Mass Production

Injection molding offers lower per-unit costs for mass production due to economies of scale, with initial tooling expenses ranging from $10,000 to $100,000, making it cost-efficient for volumes exceeding 10,000 units. Additive manufacturing, with minimal setup costs typically below $1,000, excels in low-volume prototyping and complex geometries but becomes less economical as production volume increases due to higher per-unit costs. Cost analysis reveals injection molding's advantage in large-scale manufacturing, while additive manufacturing provides flexibility and rapid iteration during the prototyping phase.

Surface Finish and Tolerances

Injection molding produces parts with superior surface finish and tight tolerances due to high-pressure metal molds and consistent material flow, achieving smooth, glossy surfaces ideal for mass production. Additive manufacturing offers greater design flexibility but typically results in rougher surfaces and wider tolerance ranges, requiring post-processing to enhance finish and dimensional accuracy. Surface roughness in additive parts can range from 5 to 20 microns, whereas injection-molded parts often achieve below 1 micron for precision applications.

Environmental Impact and Sustainability

Injection molding generates significant plastic waste and consumes large amounts of energy due to high-temperature melting processes and mold production. Additive manufacturing, also known as 3D printing, reduces material waste by building objects layer-by-layer and enables the use of biodegradable or recycled materials, lowering environmental impact. However, the energy consumption varies depending on the technology and materials used, making sustainability dependent on the specific additive process and energy sources.

Typical Industry Applications

Injection molding is predominantly used in mass production of high-volume, precision plastic parts for automotive, consumer electronics, and medical device industries due to its efficiency and low per-unit cost. Additive manufacturing excels in rapid prototyping, custom tooling, and low-volume production runs within aerospace, healthcare, and complex industrial design sectors where intricate geometries and customization are critical. Both technologies complement each other by balancing scalability and design flexibility across manufacturing workflows.

Choosing the Right Manufacturing Method

Injection molding excels in high-volume production with consistent precision, offering low per-unit costs after initial tooling investment. Additive manufacturing provides unmatched design flexibility and rapid prototyping without the need for molds, ideal for complex or customized parts in low to medium volumes. Selecting the appropriate manufacturing method depends on factors such as production volume, part complexity, lead time, and cost-efficiency requirements.

Injection molding Infographic

libterm.com

libterm.com