Compression ratio measures the efficiency of a compression algorithm by comparing the size of the compressed data to the original data size. A higher compression ratio indicates greater data reduction, which can lead to faster transmission and reduced storage requirements. Discover how understanding compression ratio can optimize Your data management and performance by reading the rest of this article.

Table of Comparison

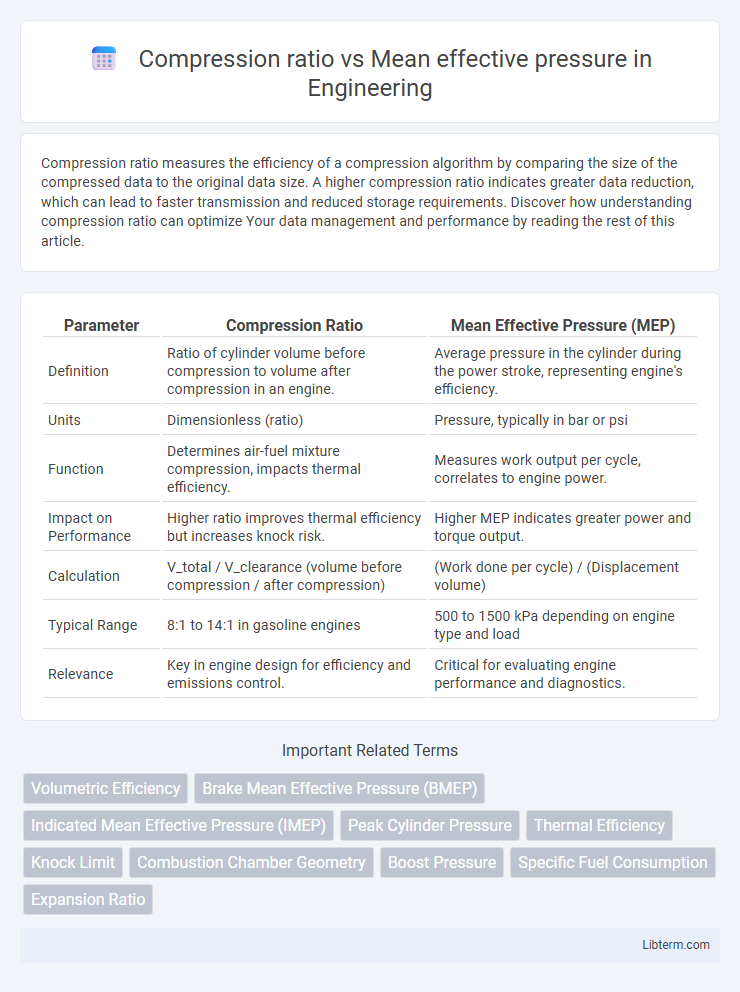

| Parameter | Compression Ratio | Mean Effective Pressure (MEP) |

|---|---|---|

| Definition | Ratio of cylinder volume before compression to volume after compression in an engine. | Average pressure in the cylinder during the power stroke, representing engine's efficiency. |

| Units | Dimensionless (ratio) | Pressure, typically in bar or psi |

| Function | Determines air-fuel mixture compression, impacts thermal efficiency. | Measures work output per cycle, correlates to engine power. |

| Impact on Performance | Higher ratio improves thermal efficiency but increases knock risk. | Higher MEP indicates greater power and torque output. |

| Calculation | V_total / V_clearance (volume before compression / after compression) | (Work done per cycle) / (Displacement volume) |

| Typical Range | 8:1 to 14:1 in gasoline engines | 500 to 1500 kPa depending on engine type and load |

| Relevance | Key in engine design for efficiency and emissions control. | Critical for evaluating engine performance and diagnostics. |

Introduction to Compression Ratio and Mean Effective Pressure

Compression ratio measures the volume difference between the cylinder's total volume and combustion chamber volume at the piston's top dead center, directly impacting engine efficiency and power output. Mean effective pressure (MEP) represents the average pressure in the combustion chamber during the power stroke, serving as a critical indicator of engine performance and work output. Understanding the relationship between compression ratio and mean effective pressure is essential for optimizing internal combustion engine design and fuel combustion efficiency.

Defining Compression Ratio in Internal Combustion Engines

Compression ratio in internal combustion engines is defined as the ratio of the total cylinder volume when the piston is at bottom dead center to the clearance volume when the piston is at top dead center. Higher compression ratios typically lead to increased mean effective pressure, enhancing engine efficiency and power output by improving the thermodynamic cycle. Understanding the impact of compression ratio on mean effective pressure is crucial for optimizing engine performance and fuel combustion.

Understanding Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) represents the average pressure exerted on the piston during the power stroke, serving as a key indicator of engine performance and efficiency. Higher compression ratios typically increase MEP by improving the air-fuel mixture's combustion efficiency, leading to greater power output and thermal efficiency. Understanding the relationship between compression ratio and MEP helps optimize engine design for enhanced fuel economy and reduced emissions.

How Compression Ratio Influences Engine Performance

Higher compression ratios increase mean effective pressure (MEP), boosting engine efficiency and power output by enabling more complete fuel combustion. Elevated compression improves thermal efficiency by maximizing the pressure and temperature in the combustion chamber, leading to better fuel economy. However, excessively high compression ratios may cause engine knocking, which necessitates advanced materials or fuel with higher octane ratings for optimal performance.

Impact of Mean Effective Pressure on Power Output

Mean effective pressure (MEP) directly influences engine power output by representing the average pressure exerted on the piston during the power stroke. Higher MEP values indicate more efficient combustion and greater force applied, leading to increased torque and horsepower, even at a constant compression ratio. Optimizing MEP enhances power output without necessarily altering the compression ratio, making it a critical factor in engine performance tuning and efficiency improvements.

Compression Ratio vs Mean Effective Pressure: Key Differences

Compression ratio directly influences mean effective pressure (MEP) by determining the engine's volumetric efficiency and combustion characteristics, with higher compression ratios generally leading to increased MEP due to improved thermal efficiency. Mean effective pressure represents the average pressure exerted on the piston during the power stroke, serving as a key indicator of engine performance, independent of engine size or speed. Understanding the distinction between compression ratio--an engine design parameter--and MEP--a performance metric--helps optimize combustion processes and engine output.

Factors Affecting Compression Ratio and MEP in Engines

Compression ratio directly influences mean effective pressure (MEP) by determining the extent of air-fuel mixture compression within the cylinder, affecting combustion efficiency and power output. Factors affecting compression ratio include piston design, cylinder volume, and combustion chamber shape, while MEP is impacted by engine load, fuel quality, and valve timing. Optimizing both parameters enhances thermal efficiency and engine performance by balancing compression-induced pressure and combustion characteristics.

Relationship Between Compression Ratio and Mean Effective Pressure

Higher compression ratios generally lead to increased mean effective pressure (MEP) in internal combustion engines, enhancing engine efficiency and power output. As compression ratio rises, the air-fuel mixture compresses more before ignition, resulting in higher combustion pressure and thus greater MEP. However, excessively high compression ratios can cause knocking, which limits the achievable MEP without advanced fuel or engine designs.

Optimizing Engine Efficiency: Balancing Compression Ratio and MEP

Optimizing engine efficiency requires balancing the compression ratio and mean effective pressure (MEP) to maximize power output while minimizing fuel consumption and emissions. Higher compression ratios improve thermal efficiency by increasing the pressure before combustion, but excessively high ratios can lead to engine knocking, limiting the achievable MEP. Engineers must carefully calibrate these parameters to enhance combustion stability and mechanical durability, ensuring optimal performance under varying load conditions.

Conclusion: Choosing the Right Balance for Engine Design

Optimal engine design requires balancing compression ratio and mean effective pressure to maximize efficiency and performance while minimizing engine knock and mechanical stress. Higher compression ratios increase thermal efficiency but raise the risk of knocking, so mean effective pressure must be managed to prevent damage and maintain reliability. Selecting the right combination depends on fuel quality, engine materials, and intended application to achieve the desired balance between power output and engine durability.

Compression ratio Infographic

libterm.com

libterm.com