Reinforced concrete combines steel reinforcement with concrete to enhance strength and durability in construction projects. Its ability to withstand tensile, compressive, and shear forces makes it a preferred material for buildings, bridges, and infrastructure. Discover more about the benefits, applications, and design techniques in the rest of the article.

Table of Comparison

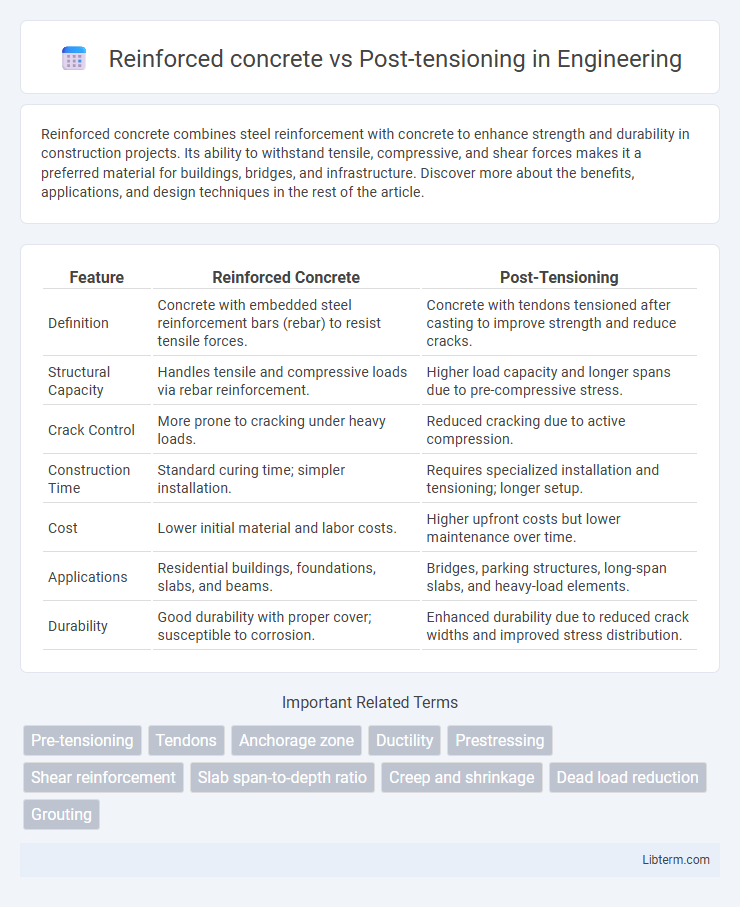

| Feature | Reinforced Concrete | Post-Tensioning |

|---|---|---|

| Definition | Concrete with embedded steel reinforcement bars (rebar) to resist tensile forces. | Concrete with tendons tensioned after casting to improve strength and reduce cracks. |

| Structural Capacity | Handles tensile and compressive loads via rebar reinforcement. | Higher load capacity and longer spans due to pre-compressive stress. |

| Crack Control | More prone to cracking under heavy loads. | Reduced cracking due to active compression. |

| Construction Time | Standard curing time; simpler installation. | Requires specialized installation and tensioning; longer setup. |

| Cost | Lower initial material and labor costs. | Higher upfront costs but lower maintenance over time. |

| Applications | Residential buildings, foundations, slabs, and beams. | Bridges, parking structures, long-span slabs, and heavy-load elements. |

| Durability | Good durability with proper cover; susceptible to corrosion. | Enhanced durability due to reduced crack widths and improved stress distribution. |

Introduction to Reinforced Concrete and Post-Tensioning

Reinforced concrete combines concrete's compressive strength with steel reinforcement's tensile strength, improving structural capacity and durability in construction projects. Post-tensioning enhances this system by applying tension to steel tendons after concrete curing, allowing for longer spans, reduced material usage, and improved crack control. This technique is essential in bridges, slabs, and large-scale buildings where increased load capacity and design flexibility are critical.

Basic Concepts and Definitions

Reinforced concrete incorporates steel bars or mesh within the concrete to enhance tensile strength, enabling it to withstand bending and shear forces. Post-tensioning involves placing high-strength steel tendons inside ducts within the concrete, then tensioning them after the concrete has cured, which introduces compressive stress to counteract tensile forces during service. The primary distinction lies in reinforcement being stationary within the structure, while post-tensioning actively applies tension to improve load-bearing capacity and control deflection.

Material Composition and Structural Elements

Reinforced concrete consists of concrete embedded with steel rebar that improves its tensile strength, while post-tensioning involves tensioning high-strength steel tendons within the concrete after it has hardened, enhancing load-carrying capacity and reducing cracking. Material composition in reinforced concrete typically includes Portland cement, aggregates, water, and carbon steel rebars, whereas post-tensioned concrete incorporates ductile steel strands or cables housed within plastic or steel ducts. Structural elements such as beams, slabs, and columns benefit from post-tensioning by enabling longer spans and thinner profiles compared to conventional reinforced concrete, optimizing material use and structural efficiency.

Design Techniques and Construction Methods

Reinforced concrete employs steel rebars embedded within concrete to enhance tensile strength, relying on passive reinforcement with fixed rebar placement before pouring concrete. Post-tensioning involves tensioning high-strength steel tendons after the concrete has cured, allowing for thinner slabs and longer spans by actively applying compressive forces to counteract tensile stresses. Design techniques for reinforced concrete focus on ensuring rebar placement and concrete cover, while post-tensioning requires careful tendon layout, stressing procedures, and anchorage systems during construction to optimize load distribution and structural efficiency.

Cost Comparison and Budget Considerations

Reinforced concrete typically involves lower initial material costs but can lead to higher labor and formwork expenses due to more extensive rebar placement and curing time. Post-tensioning reduces concrete volume and structural depth, offering cost savings in material usage and enabling longer spans with thinner slabs, which can decrease overall project costs. Budget considerations must include the specialized labor and equipment required for post-tensioning, which may raise upfront expenses but deliver long-term savings through reduced maintenance and improved structural performance.

Strength, Durability, and Performance

Reinforced concrete relies on steel rebar embedded within the concrete to withstand tensile stresses, offering reliable strength and durability for a wide range of structural applications. Post-tensioning enhances concrete performance by actively applying tension to steel tendons after concrete curing, resulting in higher load-bearing capacity, reduced cracking, and improved structural efficiency. This technique provides superior durability in aggressive environments and allows for longer spans and thinner slabs compared to conventional reinforced concrete.

Applications in Modern Construction Projects

Reinforced concrete is extensively used in residential buildings, foundations, and infrastructure due to its cost-effectiveness and strength in compression. Post-tensioning is preferred in long-span bridges, high-rise buildings, and slab foundations where enhanced load-bearing capacity and reduced material thickness are crucial. Modern construction projects leverage post-tensioning to achieve longer spans, minimize cracking, and increase structural efficiency in comparison to traditional reinforced concrete.

Advantages and Limitations of Each System

Reinforced concrete offers durability and simplicity in construction, with steel rebars providing tensile strength that complements concrete's compressive capacity, but it can be prone to cracking and requires larger cross-sections for longer spans. Post-tensioning enhances structural efficiency by applying tension to steel tendons after concrete curing, enabling thinner slabs and longer spans with reduced material usage, though it demands specialized installation procedures and higher initial costs. While reinforced concrete is widely accessible and cost-effective for general applications, post-tensioning delivers superior performance in complex or high-load structures but necessitates meticulous design and maintenance to prevent tendon corrosion and ensure longevity.

Maintenance, Repair, and Longevity Factors

Reinforced concrete typically requires more frequent maintenance due to potential corrosion of steel rebar from exposure to moisture and chloride ions, leading to cracking and spalling. Post-tensioning systems, while more complex, provide enhanced structural performance and durability by minimizing cracks and reducing concrete permeability, thereby extending service life and lowering repair frequency. Proper inspection and timely maintenance of post-tensioned structures, including tendon monitoring and corrosion protection, are crucial for maximizing longevity compared to conventional reinforced concrete.

Choosing the Right System for Your Project

Choosing the right system between reinforced concrete and post-tensioning depends on project requirements such as load capacity, span length, and cost efficiency. Reinforced concrete offers robustness and ease of construction for shorter spans, while post-tensioning provides enhanced strength and reduced structural thickness for longer spans and heavier loads. Evaluating factors like design flexibility, material savings, and maintenance needs ensures optimized structural performance and budget management.

Reinforced concrete Infographic

libterm.com

libterm.com