Maximizing production efficiency requires streamlined processes and continuous improvement to reduce costs and increase output quality. Leveraging advanced technologies and skilled labor ensures your manufacturing aligns with market demands and sustainability goals. Explore the following insights to transform your production strategy effectively.

Table of Comparison

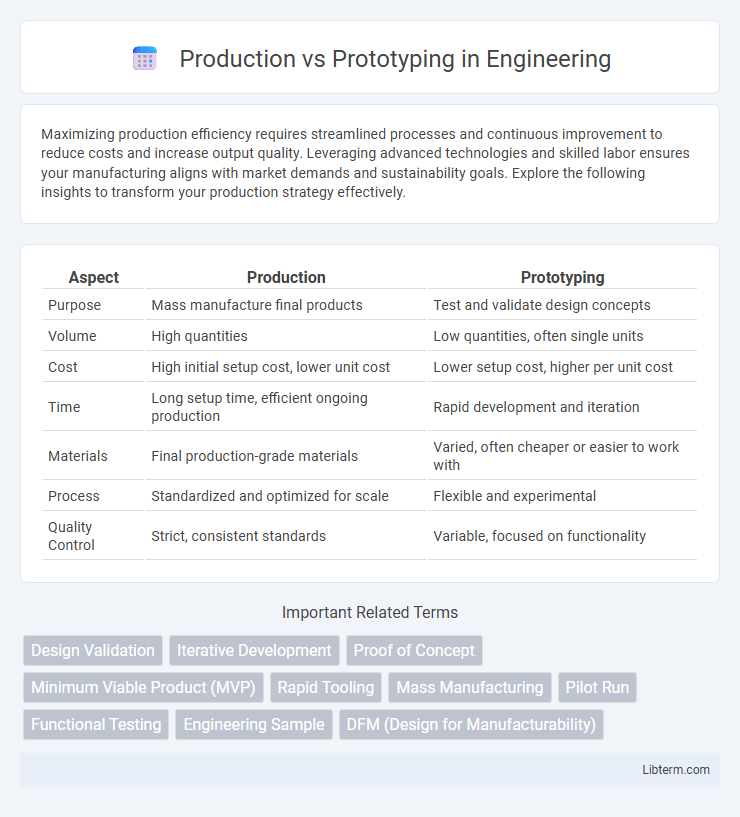

| Aspect | Production | Prototyping |

|---|---|---|

| Purpose | Mass manufacture final products | Test and validate design concepts |

| Volume | High quantities | Low quantities, often single units |

| Cost | High initial setup cost, lower unit cost | Lower setup cost, higher per unit cost |

| Time | Long setup time, efficient ongoing production | Rapid development and iteration |

| Materials | Final production-grade materials | Varied, often cheaper or easier to work with |

| Process | Standardized and optimized for scale | Flexible and experimental |

| Quality Control | Strict, consistent standards | Variable, focused on functionality |

Understanding Production vs Prototyping

Production involves manufacturing final products at scale, focusing on consistency, quality control, and cost efficiency to meet market demand. Prototyping is the iterative process of creating preliminary models to test design concepts, functionality, and usability before mass production. Understanding production vs prototyping is essential for optimizing product development timelines and ensuring successful market launches.

Key Objectives of Prototyping

Prototyping aims to validate design concepts and functionality quickly, enabling early detection of issues before full-scale production begins. It focuses on testing usability, identifying design flaws, and gathering user feedback to refine the product iteratively. Key objectives include reducing development risks, enhancing communication among stakeholders, and optimizing design efficiency prior to final manufacturing.

Main Goals of Production Processes

Production processes prioritize consistent quality, scalability, and cost efficiency to meet market demand. The main goals include maximizing output, minimizing waste, and ensuring repeatability of product specifications. Achieving high reliability and compliance with industry standards is crucial for maintaining customer satisfaction and competitive advantage.

Differences in Materials and Resources

Production uses durable, cost-efficient materials like steel, aluminum, and injection-molded plastics optimized for large-scale manufacturing, while prototyping often employs flexible, low-cost materials such as 3D-printed polymers, foam, or resin to quickly iterate designs. Resource allocation differs significantly; production demands extensive tooling, machinery, and supply chain management, whereas prototyping relies on minimal resources and rapid fabrication techniques to reduce development time. Material choices in production ensure product longevity and consistency, whereas prototyping materials prioritize ease of modification and speed over long-term durability.

Speed and Flexibility: Prototyping vs Production

Prototyping enables rapid iteration and design flexibility, allowing for quick adjustments and testing of ideas before finalizing the product. Production prioritizes speed in mass manufacturing, optimizing processes for consistent output while sacrificing some adaptability. Balancing prototyping's agility with production's efficiency is essential for innovative and scalable product development.

Cost Implications in Each Phase

Production incurs higher initial capital expenditure due to tooling, machinery, and large batch manufacturing requirements, but benefits from economies of scale that significantly reduce per-unit costs. Prototyping involves lower upfront costs by utilizing flexible techniques such as 3D printing and small-batch fabrication, yet its per-unit cost remains substantially higher due to limited quantities and iterative design changes. Efficient cost management requires balancing these phases by minimizing prototype iterations and optimizing production volume to achieve favorable cost-per-unit metrics.

Quality Assurance and Testing

Production environments demand rigorous quality assurance protocols to ensure consistent product reliability, scalability, and compliance with industry standards, while prototyping primarily focuses on iterative testing to validate design concepts and functionality. Testing during production involves comprehensive validation across performance, security, and user experience metrics, contrasting with the exploratory and adaptive testing methods used in prototyping to identify flaws early in development. Emphasizing automated testing frameworks and real-time monitoring enhances quality assurance in production, whereas prototyping benefits from rapid feedback cycles and flexible test scenarios to refine features before mass production.

Scaling Up: From Prototype to Production

Scaling up from prototype to production involves transitioning from small-scale, experimental models to large-scale manufacturing with consistent quality and efficiency. This process requires refining design specifications, optimizing production workflows, ensuring supply chain reliability, and implementing rigorous quality control measures to meet market demands. Effective scaling minimizes costs, reduces time-to-market, and supports sustainable growth while maintaining product integrity.

Challenges in Transitioning

Transitioning from prototyping to production presents significant challenges, including scaling manufacturing processes to meet volume demands without compromising quality or design integrity. Ensuring supply chain reliability and managing cost efficiency are critical as materials and components must be sourced consistently for mass production. Engineers also face difficulties in adapting prototype materials and assembly techniques to production-grade standards, requiring rigorous testing and process optimization.

Best Practices for Efficient Development

Efficient development hinges on distinguishing production from prototyping, where prototyping emphasizes rapid iteration and testing of design concepts while production focuses on scalable, high-quality output. Best practices include using modular design in prototyping to expedite changes, implementing continuous integration for seamless transitions, and establishing clear documentation standards to ensure reproducibility in production. Leveraging automation tools and maintaining close collaboration between design and engineering teams optimizes both phases, enhancing overall development speed and product reliability.

Production Infographic

libterm.com

libterm.com