Bulk modulus measures a material's resistance to uniform compression, indicating how incompressible it is when subjected to pressure. This property is essential in fields like engineering and materials science to predict how substances behave under mechanical stress. Explore the rest of the article to understand how bulk modulus impacts your applications and design choices.

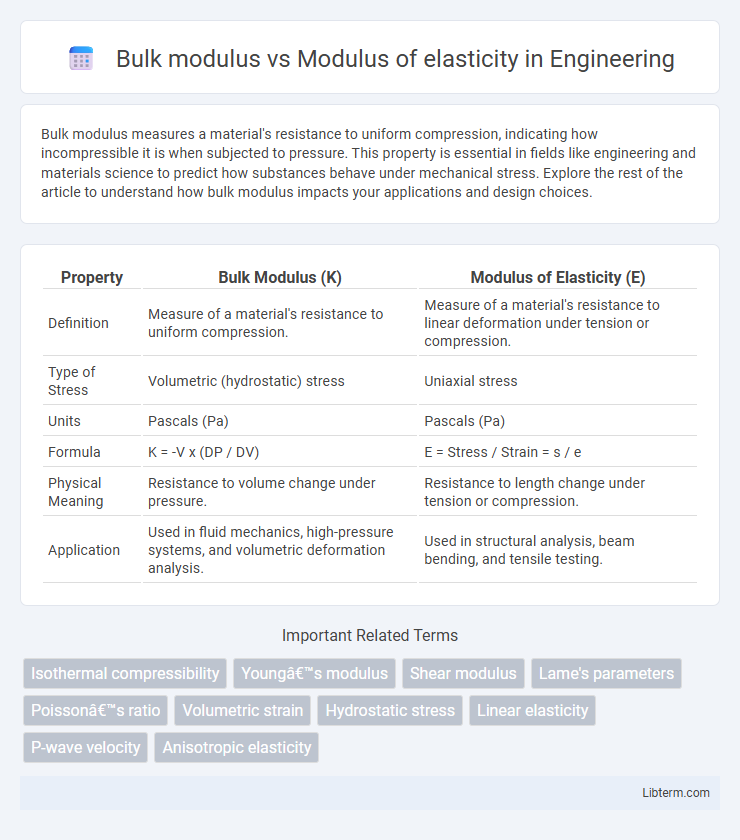

Table of Comparison

| Property | Bulk Modulus (K) | Modulus of Elasticity (E) |

|---|---|---|

| Definition | Measure of a material's resistance to uniform compression. | Measure of a material's resistance to linear deformation under tension or compression. |

| Type of Stress | Volumetric (hydrostatic) stress | Uniaxial stress |

| Units | Pascals (Pa) | Pascals (Pa) |

| Formula | K = -V x (DP / DV) | E = Stress / Strain = s / e |

| Physical Meaning | Resistance to volume change under pressure. | Resistance to length change under tension or compression. |

| Application | Used in fluid mechanics, high-pressure systems, and volumetric deformation analysis. | Used in structural analysis, beam bending, and tensile testing. |

Introduction to Modulus Concepts

Bulk modulus quantifies a material's resistance to uniform compression, measuring volume change under pressure, while modulus of elasticity (Young's modulus) gauges stiffness by assessing tensile or compressive strain along a single axis. Both moduli are fundamental mechanical properties essential for understanding material behavior under different stress conditions, with bulk modulus relevant to volumetric deformation and modulus of elasticity specific to linear deformation. These parameters are critical in engineering design for predicting material responses to applied forces.

Defining Bulk Modulus

Bulk modulus measures a material's resistance to uniform compression, quantifying the pressure required to cause a given relative decrease in volume. It represents the ratio of applied pressure to volumetric strain, distinguishing it from the modulus of elasticity, which quantifies tensile or compressive stress relative to linear strain. Understanding bulk modulus is critical in fields like fluid mechanics and material science where volumetric changes under pressure are analyzed.

Understanding Modulus of Elasticity

Modulus of elasticity, or Young's modulus, measures a material's ability to resist deformation under tensile or compressive stress, indicating stiffness in a specific direction. Bulk modulus quantifies a material's response to uniform pressure, reflecting compressibility by describing volume change under applied pressure. Understanding modulus of elasticity is crucial for designing structures subject to bending or stretching, as it directly impacts material selection for strength and flexibility.

Fundamental Differences: Bulk vs Elastic Modulus

Bulk modulus measures a material's resistance to uniform compression, representing volumetric elasticity, while modulus of elasticity, or Young's modulus, quantifies tensile or compressive stiffness along one dimension. Bulk modulus is calculated as the ratio of volumetric stress to volumetric strain under isotropic pressure, essential for fluids and solids subjected to pressure changes. In contrast, modulus of elasticity is derived from uniaxial stress and strain, crucial for understanding linear deformation in structural materials.

Mathematical Formulations and Units

Bulk modulus (K) quantifies a material's resistance to uniform compression and is mathematically defined as K = -V (DP/DV), where V is volume, DP the change in pressure, and DV the change in volume, with units in pascals (Pa). Modulus of elasticity or Young's modulus (E) measures tensile or compressive stiffness expressed as E = stress/strain = s/e, where stress (s) is force per unit area and strain (e) is the relative deformation, also measured in pascals (Pa). Both moduli relate to material elasticity but differ in application: bulk modulus addresses volumetric changes under pressure, while modulus of elasticity focuses on linear deformation under axial load.

Physical Significance in Materials Science

Bulk modulus measures a material's resistance to uniform compression, reflecting how volume decreases under applied pressure, which is crucial in understanding behaviors in liquids and isotropic solids. Modulus of elasticity, or Young's modulus, quantifies a material's stiffness under uniaxial tensile or compressive stress, indicating its ability to resist shape changes along a single axis. Both moduli provide essential insights into mechanical deformation but differ by addressing volumetric versus directional elasticity in materials science.

Application Areas and Industry Use Cases

Bulk modulus measures a material's resistance to uniform compression, critical in hydraulic systems and underwater engineering where pressure changes are significant. Modulus of elasticity, reflecting tensile stiffness, is essential in structural engineering, aerospace, and automotive industries for designing components subjected to bending and stretching forces. Both moduli guide material selection in manufacturing processes requiring specific deformation behaviors under stress conditions.

Factors Influencing Bulk and Elastic Moduli

Temperature significantly affects both bulk modulus and modulus of elasticity, typically lowering their values as thermal energy increases atomic vibrations and reduces material stiffness. Composition and microstructure, including alloying elements, grain size, and phase distribution, critically influence these moduli by altering atomic bonding and material density. Pressure and loading conditions also modify the bulk and elastic moduli, with increased pressure generally raising the bulk modulus by reducing volume compressibility, while the modulus of elasticity adapts according to the material's elastic deformation behavior under specific stress states.

Measurement Techniques and Standards

Bulk modulus measurement relies on techniques such as ultrasonic pulse velocity and hydrostatic pressure tests, following standards like ASTM D7240 and ISO 6721-10 to determine volumetric compressibility. Modulus of elasticity is typically measured using tensile or flexural testing methods conforming to ASTM E111 and ISO 527, focusing on stress-strain relationships under uniaxial loading. These standardized procedures ensure accurate quantification of material stiffness in volumetric compression for bulk modulus and linear deformation for modulus of elasticity.

Summary Table: Bulk Modulus vs Modulus of Elasticity

The Bulk Modulus quantifies a material's resistance to uniform compression, defined as the ratio of volumetric stress to volumetric strain, while the Modulus of Elasticity (Young's Modulus) measures stiffness in response to uniaxial tensile or compressive stress, expressed as stress over linear strain. Both are fundamental elastic constants but apply to different deformation modes: Bulk Modulus for volumetric changes and Modulus of Elasticity for axial deformation. The summary table highlights key differences in formulas (K = -V*DP/DV for Bulk Modulus, E = s/e for Modulus of Elasticity), typical units (Pascals), and material behaviors under pressure versus tension/compression.

Bulk modulus Infographic

libterm.com

libterm.com