Magnetic particle testing is a nondestructive testing method used to detect surface and near-surface defects in ferromagnetic materials by applying magnetic fields and iron particles. This technique helps ensure the structural integrity of critical components by revealing cracks, seams, and other discontinuities that might compromise performance. Discover how this testing method can enhance your quality control with practical insights in the rest of the article.

Table of Comparison

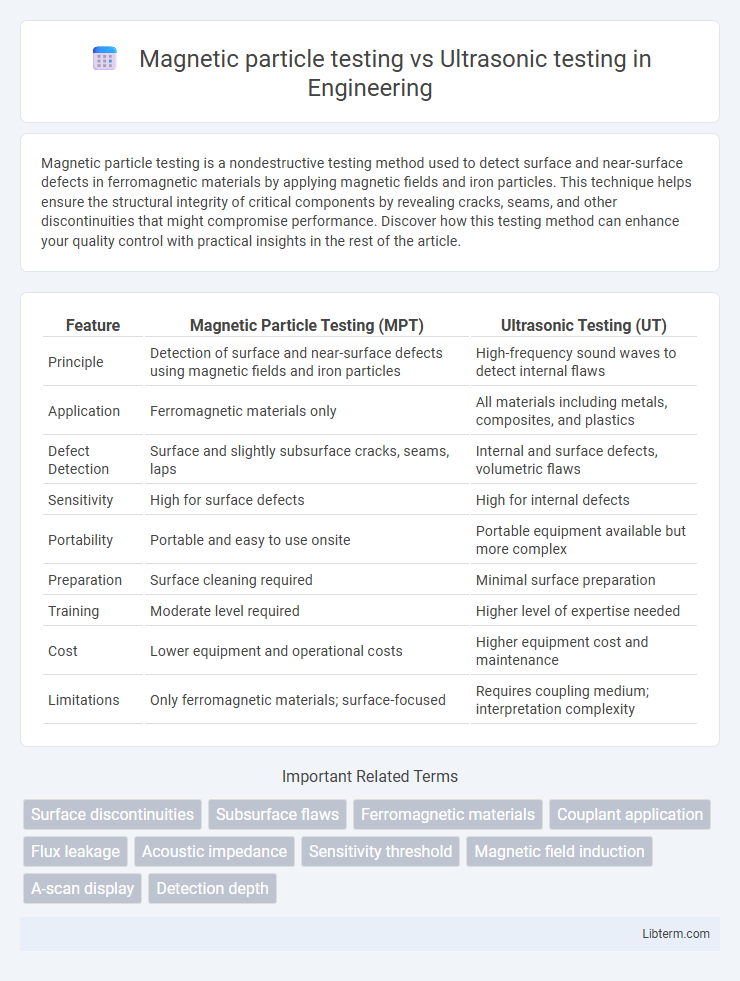

| Feature | Magnetic Particle Testing (MPT) | Ultrasonic Testing (UT) |

|---|---|---|

| Principle | Detection of surface and near-surface defects using magnetic fields and iron particles | High-frequency sound waves to detect internal flaws |

| Application | Ferromagnetic materials only | All materials including metals, composites, and plastics |

| Defect Detection | Surface and slightly subsurface cracks, seams, laps | Internal and surface defects, volumetric flaws |

| Sensitivity | High for surface defects | High for internal defects |

| Portability | Portable and easy to use onsite | Portable equipment available but more complex |

| Preparation | Surface cleaning required | Minimal surface preparation |

| Training | Moderate level required | Higher level of expertise needed |

| Cost | Lower equipment and operational costs | Higher equipment cost and maintenance |

| Limitations | Only ferromagnetic materials; surface-focused | Requires coupling medium; interpretation complexity |

Introduction to Non-Destructive Testing Methods

Magnetic particle testing (MPT) and ultrasonic testing (UT) are critical non-destructive testing (NDT) methods used to detect surface and subsurface defects in materials without causing damage. MPT is particularly effective for identifying surface discontinuities in ferromagnetic materials by applying magnetic fields and ferrous particles to reveal flaws, while UT employs high-frequency sound waves to detect and characterize internal imperfections in a wide range of materials. Both methods are essential in ensuring structural integrity and reliability in industries such as aerospace, manufacturing, and construction by enabling early defect detection and preventing failures.

Overview of Magnetic Particle Testing

Magnetic Particle Testing (MPT) is a non-destructive testing method used to detect surface and near-surface defects in ferromagnetic materials by applying a magnetic field and sprinkling ferrous particles that cluster at discontinuities. It is highly effective for identifying cracks, laps, and inclusions on components such as welds, castings, and forgings. MPT offers rapid inspection, ease of use, and immediate visual results but is limited to ferromagnetic materials, unlike Ultrasonic Testing, which can inspect a wider range of materials and detect deeper internal flaws.

Fundamentals of Ultrasonic Testing

Ultrasonic testing (UT) relies on high-frequency sound waves transmitted into materials to detect internal flaws by analyzing wave reflections or attenuations. Unlike magnetic particle testing, which requires surface magnetization and is limited to ferromagnetic materials, UT can inspect a wide range of metals and composites regardless of surface condition. The fundamental principle involves measuring the time and amplitude of ultrasonic pulses reflected from discontinuities to assess material integrity with high sensitivity and depth penetration.

Key Differences Between Magnetic Particle and Ultrasonic Testing

Magnetic particle testing (MPT) detects surface and near-surface discontinuities in ferromagnetic materials using magnetic fields and iron particles that accumulate at defect sites, offering high sensitivity to surface cracks. Ultrasonic testing (UT) employs high-frequency sound waves that penetrate materials to identify internal flaws, providing depth measurement and thickness gauging capabilities applicable to a wide range of metals and composites. Key differences include MPT's restriction to ferromagnetic materials and surface defect detection, while UT is versatile for both surface and subsurface flaws across various material types with precise defect sizing.

Applications of Magnetic Particle Testing

Magnetic Particle Testing (MPT) is primarily applied to detect surface and near-surface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and their alloys, making it ideal for inspecting welds, castings, and forgings in industries like automotive, aerospace, and petrochemical. It excels in identifying cracks, laps, seams, and corrosion-related faults on components including turbines, gears, and pipelines, where precise surface flaw detection is critical. Unlike Ultrasonic Testing (UT), which can inspect internal flaws in a wider range of materials, MPT offers rapid, cost-effective assessments with clear visual indications, enhancing quality control in routine maintenance and manufacturing processes.

Applications of Ultrasonic Testing

Ultrasonic testing (UT) is extensively applied in the aerospace, automotive, and manufacturing industries for detecting internal flaws such as cracks, voids, and inclusions in metals and composites. It excels in inspecting welds, pipes, and structural components, providing precise thickness measurements and real-time imaging without damaging the material. UT is favored for its ability to inspect complex geometries and deliver accurate results in corrosion monitoring and quality control processes.

Advantages of Magnetic Particle Testing

Magnetic Particle Testing (MPT) offers distinct advantages over Ultrasonic Testing (UT) including higher sensitivity for detecting surface and near-surface cracks in ferromagnetic materials. MPT provides rapid inspection with easily interpretable visible indications, making it ideal for locating fine surface discontinuities in steel components. Its cost-effectiveness and straightforward setup enhance efficiency in quality control and maintenance operations, especially in weld inspection and casting evaluation.

Advantages of Ultrasonic Testing

Ultrasonic testing offers deeper penetration and precise thickness measurements, enabling detection of internal flaws undetectable by magnetic particle testing. It is suitable for a wide range of materials, including non-ferromagnetic metals, providing versatile applications across industries. This method also produces digital data for accurate analysis and record-keeping, enhancing quality control processes.

Limitations and Challenges of Each Method

Magnetic particle testing is limited to detecting surface and near-surface defects in ferromagnetic materials and is ineffective on non-ferromagnetic metals or complex geometries. Ultrasonic testing faces challenges with highly attenuative or coarse-grained materials that cause signal distortion and reduced defect resolution. Both methods require skilled technicians to interpret results accurately, with magnetic particle testing often influenced by surface preparation and ultrasonic testing dependent on proper probe coupling and calibration.

Choosing the Right Testing Method for Your Needs

Magnetic particle testing excels in detecting surface and near-surface defects in ferromagnetic materials, offering rapid inspection and high sensitivity for cracks and discontinuities. Ultrasonic testing provides deeper penetration, making it ideal for volumetric inspection and material thickness measurement in a wide range of metals, including non-ferromagnetic types. Selecting the optimal testing method depends on material properties, defect location, inspection speed, and sensitivity requirements to ensure accurate and reliable results.

Magnetic particle testing Infographic

libterm.com

libterm.com