Structural dynamics examines how structures respond to loads that vary with time, such as wind, earthquakes, and traffic. Understanding this field helps ensure safety and performance by predicting vibrations, stress, and potential failures. Explore the rest of the article to discover key concepts and practical applications that can enhance your knowledge of structural dynamics.

Table of Comparison

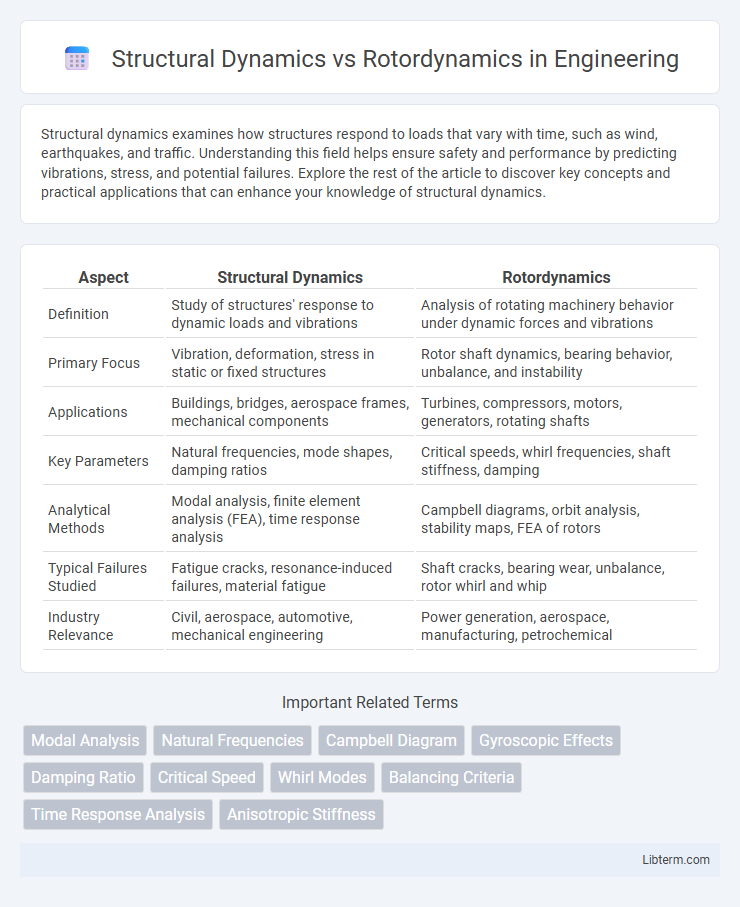

| Aspect | Structural Dynamics | Rotordynamics |

|---|---|---|

| Definition | Study of structures' response to dynamic loads and vibrations | Analysis of rotating machinery behavior under dynamic forces and vibrations |

| Primary Focus | Vibration, deformation, stress in static or fixed structures | Rotor shaft dynamics, bearing behavior, unbalance, and instability |

| Applications | Buildings, bridges, aerospace frames, mechanical components | Turbines, compressors, motors, generators, rotating shafts |

| Key Parameters | Natural frequencies, mode shapes, damping ratios | Critical speeds, whirl frequencies, shaft stiffness, damping |

| Analytical Methods | Modal analysis, finite element analysis (FEA), time response analysis | Campbell diagrams, orbit analysis, stability maps, FEA of rotors |

| Typical Failures Studied | Fatigue cracks, resonance-induced failures, material fatigue | Shaft cracks, bearing wear, unbalance, rotor whirl and whip |

| Industry Relevance | Civil, aerospace, automotive, mechanical engineering | Power generation, aerospace, manufacturing, petrochemical |

Introduction to Structural Dynamics and Rotordynamics

Structural dynamics studies the behavior of structures subjected to dynamic loads, analyzing vibrations, natural frequencies, and mode shapes to predict responses under time-dependent forces such as earthquakes or wind. Rotordynamics focuses specifically on the dynamic behavior of rotating machinery components, including shafts, rotors, and bearings, emphasizing phenomena like unbalance, gyroscopic effects, and critical speeds. Both fields utilize principles of vibration analysis and modal testing, but rotordynamics requires specialized attention to rotational effects and stability to prevent failures in turbines, compressors, and engines.

Fundamental Concepts in Structural Dynamics

Structural dynamics studies the behavior of structures subjected to dynamic loads, emphasizing the analysis of vibrations, natural frequencies, and damping characteristics to predict responses to time-varying forces. It focuses on modeling structures as continuous or discrete systems using methods like modal analysis and finite element analysis to evaluate stress, strain, and deformation under dynamic excitation. Rotordynamics, by contrast, specializes in the dynamic behavior of rotating machinery components, analyzing unbalance, gyroscopic effects, and bearing interactions to prevent vibrations that could lead to mechanical failure.

Essential Principles of Rotordynamics

Rotordynamics is a specialized field within structural dynamics that focuses on the behavior of rotating shafts and their components under dynamic loads. Essential principles of rotordynamics include understanding critical speeds, whirling motion, and vibration modes, which are crucial for predicting rotor stability and preventing resonant failures. Emphasizing the study of gyroscopic effects and bearing stiffness allows engineers to optimize rotor performance and extend the lifespan of rotating machinery.

Key Differences Between Structural Dynamics and Rotordynamics

Structural dynamics analyzes the behavior of structures subjected to dynamic loads, focusing on vibrations, deformation, and stress distribution within stationary components. Rotordynamics specifically examines the dynamic behavior of rotating shafts and components, emphasizing critical speeds, imbalance, gyroscopic effects, and stability of rotating machinery. Key differences include the rotating nature of rotordynamics systems versus stationary elements in structural dynamics, and the specialized focus on phenomena like rotor unbalance and whirl in rotordynamics.

Applications of Structural Dynamics in Engineering

Structural dynamics addresses the behavior of structures subjected to dynamic loads such as earthquakes, wind, and machinery vibrations, playing a crucial role in the design of buildings, bridges, and aerospace components to ensure safety and performance. Applications include seismic analysis for earthquake-resistant structures, vibration control in mechanical systems, and dynamic response assessment in civil infrastructure. While rotordynamics focuses specifically on the behavior of rotating machinery components like turbines and compressors, structural dynamics encompasses a broader range of engineering fields concerned with time-dependent structural responses.

Applications of Rotordynamics in Industry

Rotordynamics plays a critical role in optimizing the performance and reliability of rotating machinery such as turbines, compressors, and pumps used in aerospace, power generation, and manufacturing industries. By analyzing vibration, imbalance, and stability issues, rotordynamics helps prevent catastrophic failures and extends equipment lifespan. In contrast, structural dynamics addresses the broader response of structures to dynamic loads, but rotordynamics specializes in the behavior of rotating components under operational conditions.

Analysis Methods: Structural Dynamics vs. Rotordynamics

Structural dynamics analysis employs finite element methods (FEM) to model vibrations, transient responses, and modal characteristics of structures under dynamic loads. Rotordynamics focuses on specialized techniques such as Campbell diagrams, whirl frequency analysis, and critical speed calculations to examine rotating machinery behavior and rotor-bearing interactions. Both methodologies require time-domain simulations and frequency-domain analyses but differ in governing equations, with rotordynamics emphasizing gyroscopic effects and unbalance forces.

Common Challenges in Each Discipline

Structural dynamics faces challenges in accurately predicting natural frequencies and mode shapes under varying load conditions, which are critical for ensuring the integrity of buildings and bridges. Rotordynamics struggles with complex issues such as unbalance response, critical speed analysis, and stability of rotating shafts in turbines and compressors. Both disciplines require advanced modeling techniques and precise measurement data to mitigate vibrations and prevent mechanical failures in their respective systems.

Advances in Simulation and Modeling Techniques

Advances in simulation and modeling techniques have significantly enhanced the understanding of structural dynamics and rotordynamics by enabling more accurate predictions of vibrational behavior and fault diagnosis in rotating machinery. High-fidelity finite element models combined with multi-physics simulations allow engineers to capture complex interactions between structural components and rotating elements under various operational conditions. Machine learning algorithms and real-time data integration further optimize predictive maintenance strategies by identifying early signs of imbalance, misalignment, and rotor-stator interactions.

Future Trends in Dynamics Research

Future trends in dynamics research emphasize integrating advanced sensor technologies and AI-driven analytics within structural dynamics and rotordynamics to enhance real-time monitoring and predictive maintenance. Innovations in material science, such as lightweight composites with adaptive damping properties, are driving improved vibration control and system longevity. Emphasis on multiscale modeling and digital twins facilitates precise simulation of coupled structural and rotordynamic behaviors under complex operational conditions, promoting safer and more efficient design strategies.

Structural Dynamics Infographic

libterm.com

libterm.com