The magnetoresistive effect describes the change in electrical resistance of a material when exposed to a magnetic field. This phenomenon is fundamental in developing advanced sensors, data storage devices, and spintronic applications, where precise magnetic field detection is crucial. Discover how this effect enhances Your technology performance by exploring the detailed mechanisms and applications in the rest of the article.

Table of Comparison

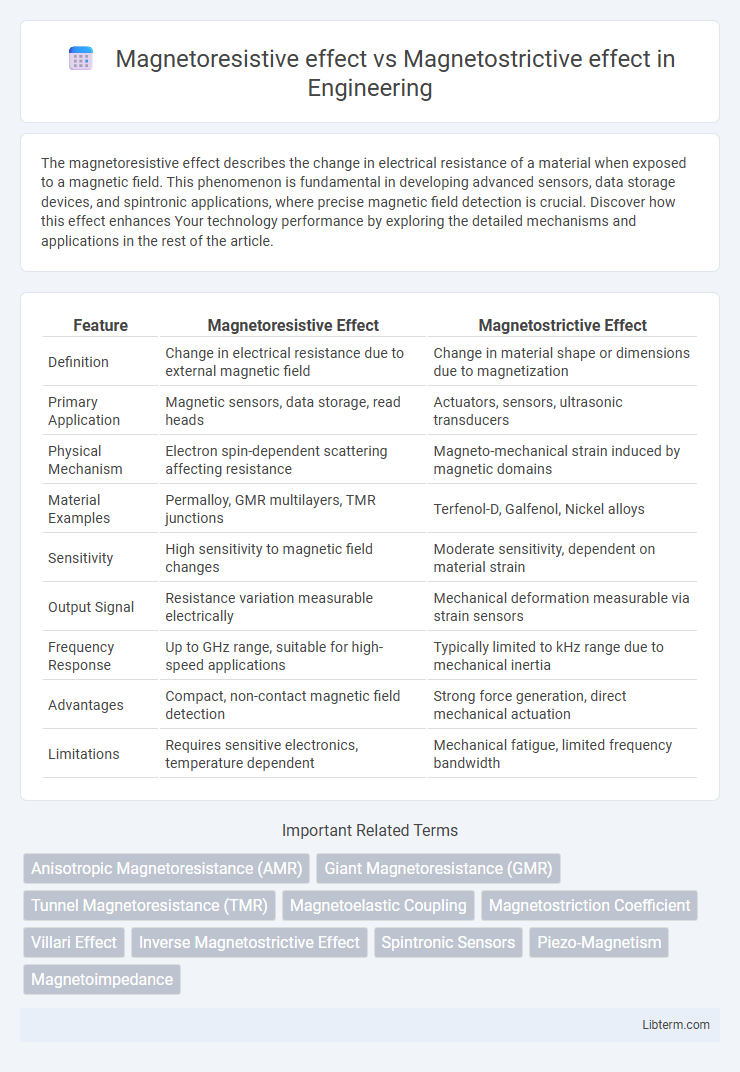

| Feature | Magnetoresistive Effect | Magnetostrictive Effect |

|---|---|---|

| Definition | Change in electrical resistance due to external magnetic field | Change in material shape or dimensions due to magnetization |

| Primary Application | Magnetic sensors, data storage, read heads | Actuators, sensors, ultrasonic transducers |

| Physical Mechanism | Electron spin-dependent scattering affecting resistance | Magneto-mechanical strain induced by magnetic domains |

| Material Examples | Permalloy, GMR multilayers, TMR junctions | Terfenol-D, Galfenol, Nickel alloys |

| Sensitivity | High sensitivity to magnetic field changes | Moderate sensitivity, dependent on material strain |

| Output Signal | Resistance variation measurable electrically | Mechanical deformation measurable via strain sensors |

| Frequency Response | Up to GHz range, suitable for high-speed applications | Typically limited to kHz range due to mechanical inertia |

| Advantages | Compact, non-contact magnetic field detection | Strong force generation, direct mechanical actuation |

| Limitations | Requires sensitive electronics, temperature dependent | Mechanical fatigue, limited frequency bandwidth |

Introduction to Magnetoresistive and Magnetostrictive Effects

The magnetoresistive effect involves the change in electrical resistance of a material when exposed to a magnetic field, utilized in sensors and data storage devices for precise magnetic field detection. The magnetostrictive effect refers to the change in shape or dimensions of a ferromagnetic material under the influence of a magnetic field, applied in actuators, sensors, and energy harvesting technologies. Both effects are fundamental in modern magnetic sensing and actuator systems, with magnetoresistance focusing on electrical property variation and magnetostriction on mechanical deformation.

Fundamental Principles of Magnetoresistive Effect

The fundamental principle of the magnetoresistive effect is the change in electrical resistance of a material when exposed to an external magnetic field, primarily due to the alignment of electron spins affecting electron scattering. This phenomenon is often observed in ferromagnetic materials where the spin-dependent scattering leads to variations in resistance that can be precisely measured. In contrast, the magnetostrictive effect involves a change in the physical dimensions of a material caused by magnetization, highlighting fundamentally different mechanisms between electrical resistance variations and structural deformation.

Fundamentals of Magnetostrictive Effect

The magnetostrictive effect arises from the change in the shape or dimensions of ferromagnetic materials when subjected to a magnetic field, caused by the rotation of magnetic domains aligning with the field. This effect is fundamentally due to the strain generated by the magneto-mechanical coupling within the crystal lattice, resulting in measurable elongation or contraction. In contrast, the magnetoresistive effect involves changes in electrical resistance due to magnetic field variations, focusing on electron transport rather than mechanical deformation.

Microscopic Mechanisms: Resistance vs Deformation

The magnetoresistive effect originates from the spin-dependent scattering of conduction electrons, which alters electrical resistance when exposed to a magnetic field. Conversely, the magnetostrictive effect is driven by the realignment of magnetic domains causing lattice deformation and mechanical strain within the material. These microscopic mechanisms distinguish magnetoresistance as an electronic transport phenomenon, while magnetostriction manifests as a magnetoelastic coupling altering physical dimensions.

Key Materials Exhibiting Magnetoresistive Properties

Key materials exhibiting magnetoresistive properties include transition metal oxides such as manganites (La1-xSrxMnO3) and intermetallic alloys like Heusler compounds (Co2MnSi), which demonstrate colossal magnetoresistance (CMR) and giant magnetoresistance (GMR) effects respectively. Thin-film multilayer structures composed of alternating ferromagnetic and nonmagnetic layers, especially those made from cobalt, iron, and nickel alloys, are widely utilized for GMR-based sensors and data storage devices. Spintronic materials like magnetic tunnel junctions (MTJs) employing MgO barriers exhibit tunneling magnetoresistance (TMR) critical for modern magnetic random-access memory (MRAM) technologies.

Key Materials Exhibiting Magnetostrictive Properties

Key materials exhibiting magnetostrictive properties include Terfenol-D, an alloy of terbium, dysprosium, and iron known for its exceptionally high magnetostriction and wide operating temperature range. Galfenol, composed of iron and gallium, offers moderate magnetostrictive strain with enhanced mechanical strength and corrosion resistance. These materials are essential in sensors, actuators, and energy harvesting devices, where magnetostrictive effects convert magnetic energy into mechanical strain.

Technological Applications of Magnetoresistive Effect

The magnetoresistive effect, which involves changes in electrical resistance under a magnetic field, underpins key technological applications such as magnetic sensors, read heads in hard disk drives, and magnetoresistive random-access memory (MRAM). These applications exploit the giant magnetoresistance (GMR) and tunneling magnetoresistance (TMR) phenomena to achieve high sensitivity and data storage density. In contrast, the magnetostrictive effect, characterized by a material's dimensional change due to magnetization, is primarily used in actuators and sensors but offers different operational principles and performance metrics.

Technological Applications of Magnetostrictive Effect

The magnetostrictive effect causes materials to change shape or dimensions under a magnetic field, enabling precise sensors and actuators in industrial automation and robotics. This effect is fundamental in designing high-performance ultrasonic transducers for medical imaging and nondestructive testing, improving accuracy and sensitivity. Magnetostrictive materials also play a crucial role in developing energy-efficient vibration control systems in automotive and aerospace applications.

Comparative Analysis: Magnetoresistance vs Magnetostriction

Magnetoresistive effect involves the change in electrical resistance of a material under an external magnetic field, widely utilized in magnetic sensors and data storage devices due to its high sensitivity and fast response. Magnetostrictive effect refers to the change in the shape or dimensions of a material when subjected to a magnetic field, primarily exploited in actuators and transducers for mechanical motion control. Compared to magnetoresistance, magnetostriction offers mechanical deformation benefits but generally slower response times, while magnetoresistive materials provide superior electrical signal modulation without mechanical strain.

Future Trends and Innovations in Magnetic Effects

Future trends in magnetic effects emphasize the integration of magnetoresistive sensors into ultra-low power electronics and high-density data storage systems, leveraging advances in spintronics and nanoscale fabrication techniques. Innovations in magnetostrictive materials focus on enhanced mechanical-to-magnetic energy conversion for applications in wireless sensors, energy harvesting, and tunable actuators with increased sensitivity and durability. Research on hybrid devices combining magnetoresistive and magnetostrictive effects aims to achieve multifaceted functionalities, enabling breakthroughs in next-generation wearable technologies and adaptive smart materials.

Magnetoresistive effect Infographic

libterm.com

libterm.com