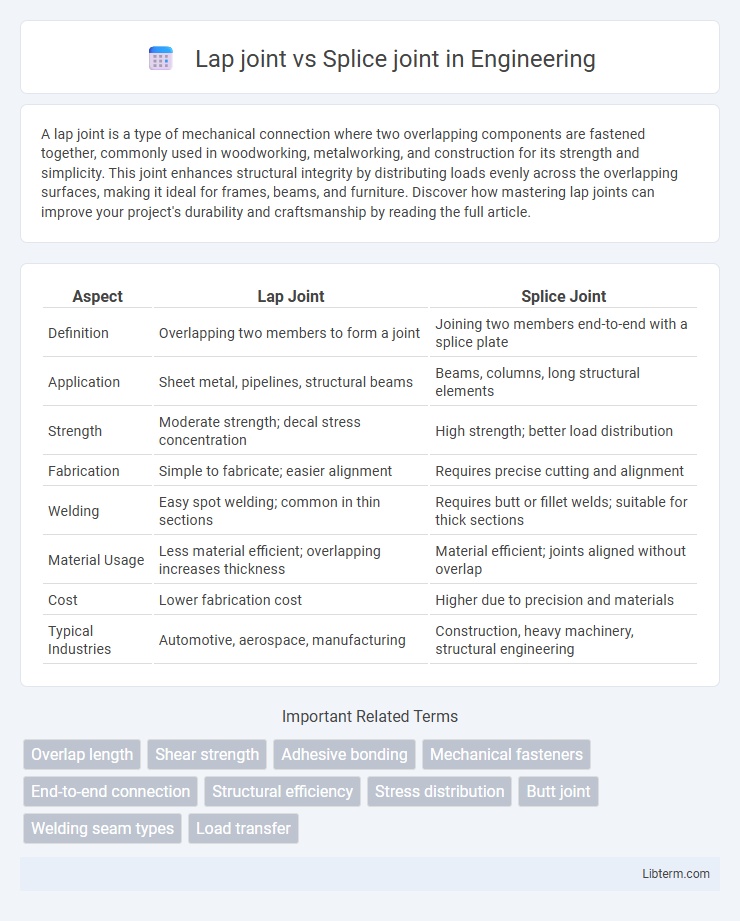

A lap joint is a type of mechanical connection where two overlapping components are fastened together, commonly used in woodworking, metalworking, and construction for its strength and simplicity. This joint enhances structural integrity by distributing loads evenly across the overlapping surfaces, making it ideal for frames, beams, and furniture. Discover how mastering lap joints can improve your project's durability and craftsmanship by reading the full article.

Table of Comparison

| Aspect | Lap Joint | Splice Joint |

|---|---|---|

| Definition | Overlapping two members to form a joint | Joining two members end-to-end with a splice plate |

| Application | Sheet metal, pipelines, structural beams | Beams, columns, long structural elements |

| Strength | Moderate strength; decal stress concentration | High strength; better load distribution |

| Fabrication | Simple to fabricate; easier alignment | Requires precise cutting and alignment |

| Welding | Easy spot welding; common in thin sections | Requires butt or fillet welds; suitable for thick sections |

| Material Usage | Less material efficient; overlapping increases thickness | Material efficient; joints aligned without overlap |

| Cost | Lower fabrication cost | Higher due to precision and materials |

| Typical Industries | Automotive, aerospace, manufacturing | Construction, heavy machinery, structural engineering |

Introduction to Lap Joints and Splice Joints

Lap joints and splice joints are fundamental welding techniques used to join two metal pieces. Lap joints overlap two materials, creating a strong, durable connection ideal for varying thicknesses and load-bearing structures. Splice joints align pieces end-to-end, often reinforced with welding or mechanical fasteners, making them suitable for extending lengths of metal components.

Definition and Key Differences

A lap joint is a type of joint where two pieces of material overlap each other and are fastened together, commonly used in woodworking and metalworking for its simplicity and strength. A splice joint, on the other hand, connects two pieces end-to-end to extend the length of the material, frequently employed in structural applications where continuity is essential. Key differences include the lap joint's overlapping design for increased surface area and load distribution versus the splice joint's end-to-end alignment optimized for linear extension and minimal profile.

Common Applications in Construction

Lap joints are commonly used in steel frame construction, metal roofing, and wooden panel assemblies due to their strength and ease of welding or fastening. Splice joints find frequent application in joining structural steel beams, timber lengths, and concrete elements where extending material length or repairing sections is necessary. Both joint types provide essential functions in building frameworks, with lap joints preferred for overlapping connections and splice joints for end-to-end continuity.

Structural Strength and Load Distribution

Lap joints provide superior structural strength by overlapping materials, creating a larger bonding area that distributes loads more evenly across the joint, reducing stress concentrations. Splice joints rely on end-to-end connections which may introduce localized stress points, potentially compromising load transfer efficiency under heavy or dynamic loads. In applications requiring high load-bearing capacity and enhanced durability, lap joints are typically favored for their ability to maintain integrity under complex load conditions.

Installation Process and Techniques

Lap joints require overlapping two materials and fastening them through welding, bolting, or riveting, allowing easy alignment during installation. Splice joints involve joining two separate material ends, typically using connectors or welding, demanding precise edge preparation and alignment to ensure structural integrity. The installation of lap joints is generally faster due to simpler positioning, while splice joints offer stronger continuity for extended lengths but require more meticulous technique.

Material Compatibility

Lap joints offer excellent material compatibility for joining similar or dissimilar metals due to overlapping surfaces that enhance bonding strength and distribute stress evenly. Splice joints are ideal for extending lengths of the same material, providing uniform strength along the joint but may require precise alignment to prevent weaknesses, especially in heterogeneous material combinations. Selecting the appropriate joint depends on material properties such as thermal expansion, corrosion resistance, and mechanical load requirements to ensure durability and performance.

Cost Comparison and Efficiency

Lap joints generally offer lower manufacturing costs due to simpler alignment and welding processes, making them efficient for quick assembly in sheet metal and structural applications. Splice joints, while potentially more expensive due to additional preparation and precise fitting, provide higher structural integrity and load distribution, increasing long-term efficiency in critical construction and piping systems. Choosing between lap and splice joints depends on balancing upfront cost savings against the need for durability and performance in application-specific contexts.

Durability and Maintenance

Lap joints offer superior durability due to their overlapping design, which distributes stress more evenly and reduces the likelihood of joint failure under load or vibration. Splice joints, while easier to fabricate and align, generally require more frequent maintenance because their end-to-end connection is more susceptible to stress concentration and environmental damage. Proper sealing and regular inspection are critical in splice joints to prevent corrosion and ensure long-term performance.

Pros and Cons of Lap Joints

Lap joints provide strong, durable connections ideal for load-bearing structures and offer excellent resistance to shear forces, making them suitable for metal and woodworking applications. However, they consume more material and can create uneven surfaces, which may require additional finishing or reinforcement. Compared to splice joints, lap joints are easier to fabricate but may not be as efficient in aligning long structural members.

Pros and Cons of Splice Joints

Splice joints provide a reliable method for extending the length of materials, especially in structural applications where continuity is critical. They allow for strong connections while minimizing material overlap compared to lap joints, but require precise alignment and can be more complex to fabricate. The main drawbacks include potential stress concentration at the joint and susceptibility to joint failure if not properly reinforced or manufactured.

Lap joint Infographic

libterm.com

libterm.com