Process time refers to the duration required to complete a specific task or operation, often critical in manufacturing, computing, or service industries. Understanding process time helps optimize workflows, reduce delays, and improve overall efficiency in your projects. Explore the rest of the article to learn how to accurately measure and minimize process time for better productivity.

Table of Comparison

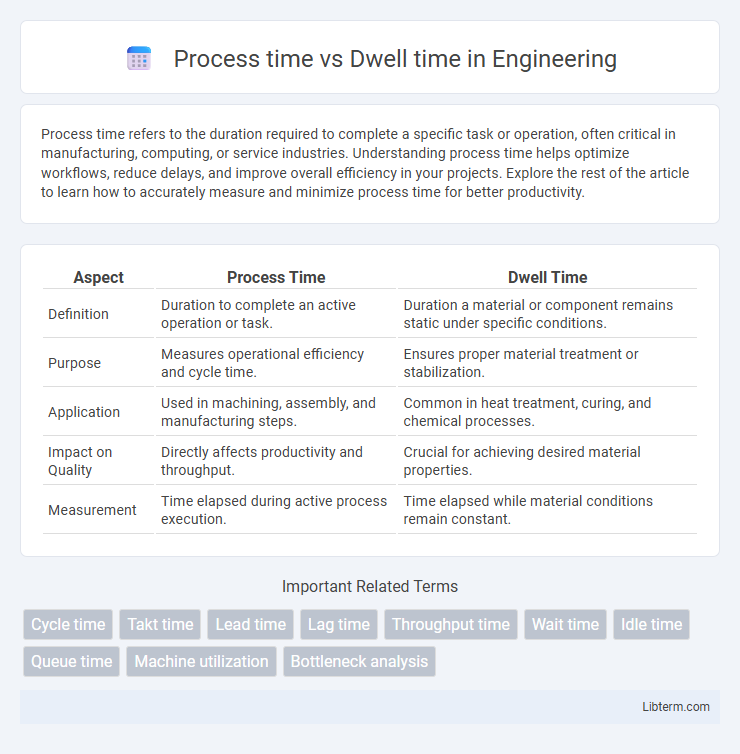

| Aspect | Process Time | Dwell Time |

|---|---|---|

| Definition | Duration to complete an active operation or task. | Duration a material or component remains static under specific conditions. |

| Purpose | Measures operational efficiency and cycle time. | Ensures proper material treatment or stabilization. |

| Application | Used in machining, assembly, and manufacturing steps. | Common in heat treatment, curing, and chemical processes. |

| Impact on Quality | Directly affects productivity and throughput. | Crucial for achieving desired material properties. |

| Measurement | Time elapsed during active process execution. | Time elapsed while material conditions remain constant. |

Understanding Process Time and Dwell Time

Process time refers to the actual duration required for completing a specific task or operation within a manufacturing or service procedure, excluding any waiting periods. Dwell time represents the period during which an item or material remains idle or stationary between process steps, often due to queueing or setup delays. Understanding the distinction between process time and dwell time is crucial for optimizing workflow efficiency and reducing total cycle time in production or service systems.

Key Differences Between Process Time and Dwell Time

Process time refers to the actual duration spent performing a specific task or operation within a manufacturing or service workflow, while dwell time indicates the period an item or component remains idle or waiting between process steps. The key difference lies in process time being active work duration, whereas dwell time represents inactivity or delay impacting overall throughput and efficiency. Optimizing process time reduces cycle duration, but minimizing dwell time enhances flow efficiency and resource utilization in production systems.

Importance of Monitoring Process Time

Monitoring process time is critical for optimizing manufacturing efficiency and reducing production costs. Accurate measurement of process time enables identification of bottlenecks and ensures timely adjustments to maintain product quality and consistency. Dwell time impacts product characteristics, but understanding process time allows for better control over overall cycle time and resource allocation.

Significance of Tracking Dwell Time

Tracking dwell time is crucial for optimizing manufacturing processes, as it directly impacts product quality and operational efficiency. Dwell time measures the duration a material or component remains in a specific process step, allowing precise control over heat treatment, curing, or machining cycles. Monitoring dwell time helps identify bottlenecks, reduce defects, and ensure consistent adherence to process specifications, ultimately enhancing productivity and reducing costs.

Factors Influencing Process Time

Process time is significantly influenced by factors such as machine efficiency, operator skill, and raw material quality, which collectively determine the duration of each production cycle. Dwell time, often considered a subset of process time, depends on specific operational requirements like curing, heating, or setting phases within the manufacturing process. Optimizing process time involves balancing these factors to enhance throughput while maintaining product quality and minimizing idle periods.

Variables Affecting Dwell Time

Dwell time is influenced by variables such as customer engagement, content relevance, and page load speed, while process time primarily depends on operational efficiency and task complexity. Factors like user intent, navigation ease, and multimedia elements prolong dwell time by increasing interaction depth. Monitoring these variables allows optimization of user experience and boosts overall process effectiveness.

Process Time vs Dwell Time in Manufacturing

Process time in manufacturing refers to the actual duration required to perform a specific operation or production step, directly impacting overall efficiency. Dwell time, on the other hand, denotes the period when a product or component remains idle or stationary between process steps, often contributing to delays and reduced throughput. Minimizing dwell time while optimizing process time enhances manufacturing productivity and reduces cycle times in production lines.

Impact on Operational Efficiency

Process time directly affects cycle time and throughput, determining how quickly tasks move through production stages. Dwell time, representing idle or waiting periods between processes, can cause bottlenecks and reduce overall equipment effectiveness (OEE). Minimizing dwell time and optimizing process time enhance operational efficiency by increasing output rates and reducing lead times.

Methods to Reduce Process and Dwell Times

Reducing process and dwell times can be achieved through lean manufacturing techniques such as value stream mapping, which identifies and eliminates non-value-added steps. Implementing automation and real-time monitoring systems accelerates operations and minimizes idle periods. Continuous employee training and standardized workflows further enhance efficiency, decreasing both process duration and dwell intervals.

Best Practices for Process and Dwell Time Optimization

Optimizing process time and dwell time involves identifying bottlenecks and streamlining workflow to maximize productivity and minimize idle periods. Implementing real-time monitoring systems and predictive analytics helps in dynamically adjusting process parameters and reducing unnecessary dwell time. Standardizing procedures and regularly reviewing process performance enable continuous improvement and ensure optimal use of resources.

Process time Infographic

libterm.com

libterm.com