Surface hardness determines a material's resistance to deformation, wear, and scratching, playing a crucial role in applications ranging from industrial tools to everyday products. High surface hardness enhances durability and performance, making it essential for selecting materials in manufacturing and engineering. Discover how surface hardness impacts your projects and learn about measurement techniques in the rest of this article.

Table of Comparison

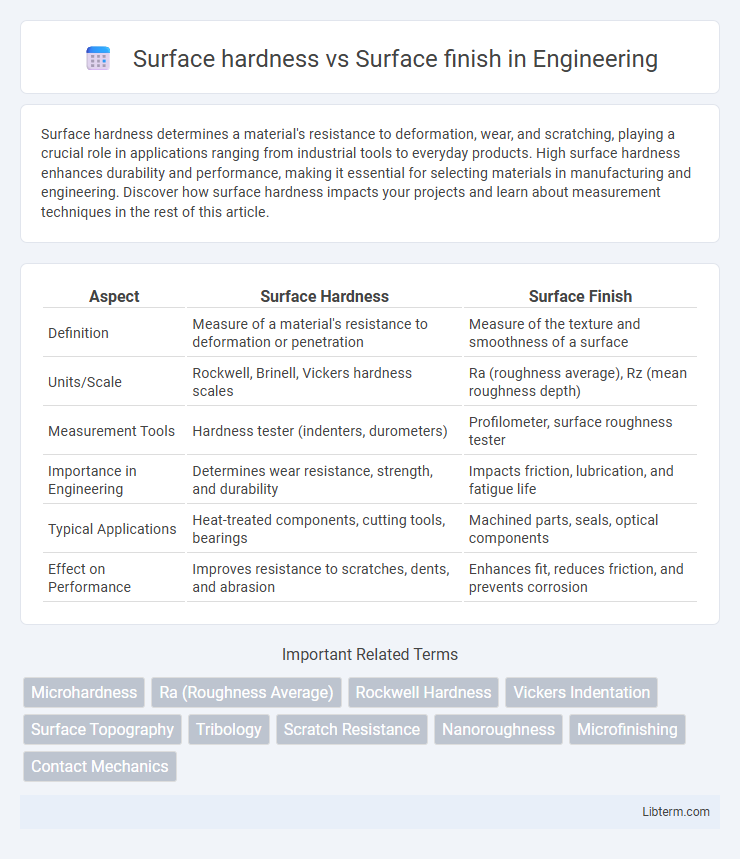

| Aspect | Surface Hardness | Surface Finish |

|---|---|---|

| Definition | Measure of a material's resistance to deformation or penetration | Measure of the texture and smoothness of a surface |

| Units/Scale | Rockwell, Brinell, Vickers hardness scales | Ra (roughness average), Rz (mean roughness depth) |

| Measurement Tools | Hardness tester (indenters, durometers) | Profilometer, surface roughness tester |

| Importance in Engineering | Determines wear resistance, strength, and durability | Impacts friction, lubrication, and fatigue life |

| Typical Applications | Heat-treated components, cutting tools, bearings | Machined parts, seals, optical components |

| Effect on Performance | Improves resistance to scratches, dents, and abrasion | Enhances fit, reduces friction, and prevents corrosion |

Introduction to Surface Hardness and Surface Finish

Surface hardness measures a material's resistance to deformation, impacting wear resistance and durability in manufacturing. Surface finish refers to the texture and smoothness of a material's top layer, influencing friction, appearance, and functionality. Both properties are critical in engineering applications, affecting product performance and lifespan.

Defining Surface Hardness: Key Concepts

Surface hardness refers to the resistance of a material's surface to indentation, scratching, or deformation and is measured using methods such as Rockwell, Brinell, and Vickers tests. It directly impacts wear resistance, fatigue strength, and the longevity of components in industries like aerospace, automotive, and manufacturing. Unlike surface finish, which describes the texture and appearance, surface hardness defines the mechanical properties of the surface layer critical for functional performance.

Understanding Surface Finish: Parameters and Importance

Surface finish, characterized by parameters such as roughness (Ra), waviness, and lay, significantly influences the performance and functionality of machined parts. Precise control of surface finish impacts friction, wear resistance, and aesthetic quality, making it vital in industries like aerospace and automotive manufacturing. Understanding these parameters enables engineers to optimize machining processes for improved durability and efficiency.

Measurement Techniques for Surface Hardness

Surface hardness measurement techniques include Rockwell, Vickers, Brinell, and Knoop tests, each utilizing specific indenters and load applications to quantify resistance to deformation. These methods provide precise hardness values essential for assessing material durability and wear resistance, unlike surface finish, which quantifies texture parameters like roughness using profilometers and optical instruments. Accurate hardness evaluation influences manufacturing quality and component longevity by ensuring that surface treatment processes achieve desired mechanical properties.

Methods for Assessing Surface Finish

Surface finish is typically assessed using methods such as profilometry, which measures surface roughness parameters like Ra, Rz, and Rt to quantify texture. Optical techniques such as interferometry and confocal microscopy provide high-resolution, non-contact surface topography analysis. Tactile methods, including stylus profilometers, physically trace the surface to generate detailed roughness profiles critical for evaluating machining and finishing processes.

Factors Affecting Surface Hardness

Surface hardness is primarily influenced by factors such as material composition, heat treatment, and the presence of alloying elements, which alter the microstructure and increase resistance to deformation. Surface finish, characterized by roughness and texture, impacts surface hardness measurements by affecting the contact area and potential stress concentration points. Machining processes, thermal effects, and surface contamination also play a crucial role in determining the final surface hardness of a material.

Factors Influencing Surface Finish

Surface finish is influenced by factors such as cutting speed, tool geometry, feed rate, and machining vibrations, which directly affect the texture and quality of the machined surface. Material properties, including hardness and ductility, impact the ease of chip formation and surface irregularities during the operation. Proper selection of machining parameters and tool conditions optimizes surface finish, balancing surface hardness requirements for wear resistance and performance.

Relationship Between Surface Hardness and Surface Finish

Surface hardness directly influences the surface finish by affecting the material's resistance to deformation during machining processes. Harder surfaces typically result in smoother finishes due to less material displacement and reduced tool wear. Conversely, softer materials may produce rougher finishes as they tend to deform more easily, impacting the final surface texture and quality.

Industrial Applications: Why Surface Properties Matter

Surface hardness directly influences wear resistance, durability, and load-bearing capacity in industrial applications, ensuring components withstand operational stresses without deforming. Surface finish impacts friction, lubrication retention, and fatigue life, affecting the efficiency and longevity of mechanical parts. Optimizing both properties enhances performance in sectors such as automotive manufacturing, aerospace engineering, and precision machining.

Optimizing Both Surface Hardness and Surface Finish

Optimizing surface hardness and surface finish involves balancing material properties and machining parameters to achieve durability and aesthetic quality simultaneously. Applying techniques such as controlled heat treatment and precision grinding can enhance hardness while maintaining a smooth surface texture. Advanced coatings like PVD or DLC improve hardness without compromising the surface finish, ensuring improved wear resistance and reduced friction.

Surface hardness Infographic

libterm.com

libterm.com