Rolling friction occurs when a round object, like a wheel or ball, rolls over a surface, creating resistance that slows motion. This type of friction is generally much lower than sliding friction, allowing vehicles and machinery to move more efficiently. Discover how rolling friction impacts your daily life and the engineering solutions designed to optimize it in the rest of this article.

Table of Comparison

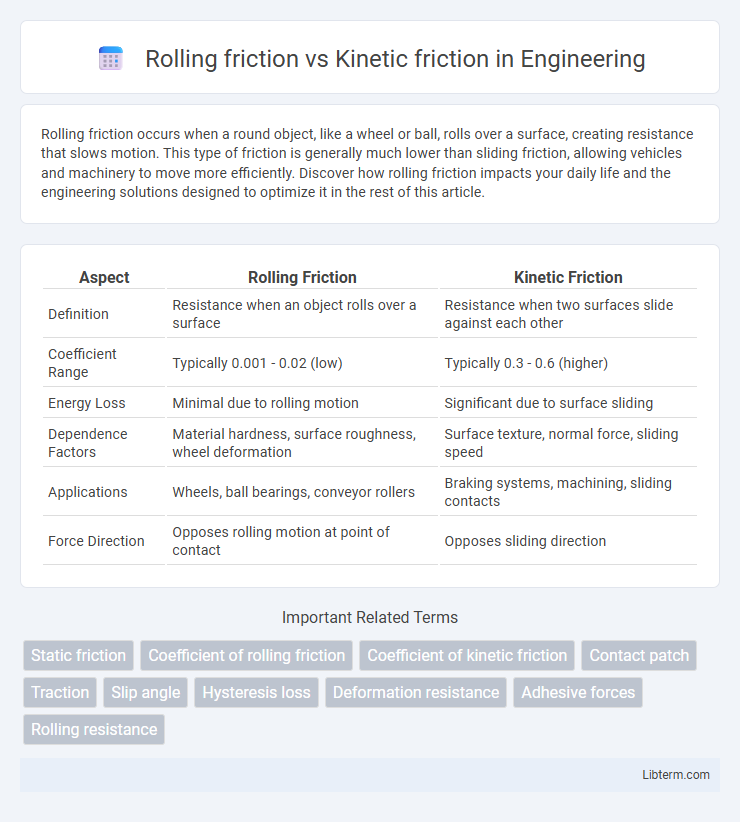

| Aspect | Rolling Friction | Kinetic Friction |

|---|---|---|

| Definition | Resistance when an object rolls over a surface | Resistance when two surfaces slide against each other |

| Coefficient Range | Typically 0.001 - 0.02 (low) | Typically 0.3 - 0.6 (higher) |

| Energy Loss | Minimal due to rolling motion | Significant due to surface sliding |

| Dependence Factors | Material hardness, surface roughness, wheel deformation | Surface texture, normal force, sliding speed |

| Applications | Wheels, ball bearings, conveyor rollers | Braking systems, machining, sliding contacts |

| Force Direction | Opposes rolling motion at point of contact | Opposes sliding direction |

Introduction to Friction: Rolling vs Kinetic

Rolling friction occurs when an object rolls over a surface, resulting in less resistance due to the smaller area of contact compared to kinetic friction, which arises when two surfaces slide against each other and typically involves greater energy loss. The coefficient of rolling friction is significantly lower than that of kinetic friction, making rolling motion more efficient in mechanical systems such as wheels and bearings. Understanding the distinctions between rolling friction and kinetic friction is essential for optimizing energy consumption and wear in engineering applications.

Defining Rolling Friction

Rolling friction refers to the resistive force that opposes the motion of a rolling object over a surface, typically much lower than kinetic friction experienced during sliding. It arises due to deformations at the contact point between the rolling object and the surface, leading to energy loss mainly through hysteresis in materials. Unlike kinetic friction, which occurs when two surfaces slide against each other, rolling friction enables smoother motion with reduced energy dissipation.

Understanding Kinetic Friction

Kinetic friction occurs when two surfaces slide past each other, causing resistance proportional to the normal force and the kinetic friction coefficient. Unlike rolling friction, which is significantly lower due to the deformation and recovery of rolling objects, kinetic friction involves continuous surface contact and molecular adhesion leading to energy dissipation. Understanding kinetic friction is essential for analyzing motion dynamics, energy loss, and wear in mechanical systems involving sliding components.

Key Differences Between Rolling and Kinetic Friction

Rolling friction occurs when an object rolls over a surface, resulting in much lower resistance due to minimal deformation at the contact points, while kinetic friction acts between sliding surfaces and generates higher resistance because of continuous surface contact and microscopic irregularities. Rolling friction depends on factors such as wheel radius, surface texture, and the object's weight, whereas kinetic friction is influenced primarily by the nature of the surfaces and the normal force pressing them together. Unlike kinetic friction, rolling friction produces less heat and energy loss, enabling more efficient motion in vehicles and machinery.

Factors Affecting Rolling Friction

Rolling friction depends significantly on factors such as the material properties of both the rolling object and the surface, the radius of the rolling object, and the load or weight applied. Deformation of the surfaces in contact and the presence of lubrication also influence rolling friction, typically making it lower than kinetic friction. Unlike kinetic friction, which mainly depends on surface roughness and sliding velocity, rolling friction is more sensitive to the elasticity and hardness of the contacting materials.

Factors Influencing Kinetic Friction

Kinetic friction depends on surface roughness, material properties, and the normal force between contacting surfaces, directly affecting the resistance encountered during sliding motion. Unlike rolling friction, which is significantly lower due to the minimal deformation of rolling objects, kinetic friction generates more heat and wear because of continuous surface asperity interactions. Factors such as lubrication, temperature, and velocity further influence the magnitude of kinetic friction, altering energy loss and system efficiency in mechanical applications.

Real-World Examples of Rolling Friction

Rolling friction occurs when an object rolls over a surface, such as car tires on asphalt or bowling balls on a polished lane, resulting in significantly lower resistance compared to kinetic friction, which acts during sliding motion. The reduced energy loss in rolling friction explains why conveyor belts and ball bearings are widely used in industrial machinery to improve efficiency. Real-world examples like bicycle wheels and train wheels demonstrate how rolling friction minimizes wear and tear while enabling smooth movement over long distances.

Practical Applications of Kinetic Friction

Kinetic friction plays a crucial role in practical applications such as vehicle braking systems, where it dissipates energy to slow down motion effectively. It is also essential in machinery involving sliding parts, ensuring controlled movement and preventing slipping. Unlike rolling friction, which minimizes resistance in wheels and bearings, kinetic friction provides the necessary grip and traction for safety and operational efficiency.

Reducing Friction: Strategies and Technologies

Reducing rolling friction involves optimizing wheel and surface materials, such as using lubricated ball bearings and smooth, hard surfaces to minimize deformation and energy loss. In contrast, kinetic friction reduction relies heavily on surface coatings like PTFE and the application of lubricants to decrease direct surface contact and sliding resistance. Advanced technologies such as magnetic levitation and smart adaptive surfaces are revolutionizing friction management by significantly lowering both rolling and kinetic friction in industrial and transportation applications.

Rolling Friction vs Kinetic Friction: Summary and Comparison

Rolling friction occurs when an object rolls over a surface, generally offering lower resistance compared to kinetic friction, which acts between sliding surfaces in relative motion. Rolling friction depends on factors like the deformation of the rolling object and the surface, while kinetic friction primarily depends on the nature of the contacting materials and the normal force. In summary, rolling friction enables easier movement due to minimal energy loss, whereas kinetic friction requires more energy to overcome sliding resistance.

Rolling friction Infographic

libterm.com

libterm.com