Thermal balancing ensures that heating and cooling systems distribute temperatures evenly throughout a building, preventing hot or cold spots and maximizing energy efficiency. Proper thermal balance improves comfort, reduces utility costs, and extends the lifespan of HVAC equipment. Explore the rest of the article to discover how thermal balancing can optimize your home's climate control.

Table of Comparison

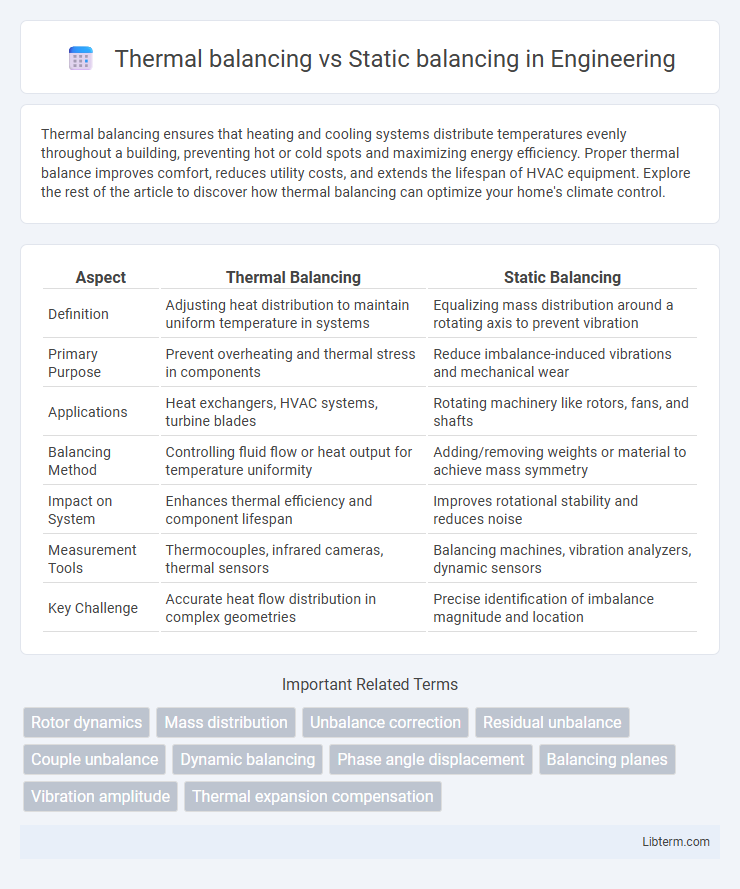

| Aspect | Thermal Balancing | Static Balancing |

|---|---|---|

| Definition | Adjusting heat distribution to maintain uniform temperature in systems | Equalizing mass distribution around a rotating axis to prevent vibration |

| Primary Purpose | Prevent overheating and thermal stress in components | Reduce imbalance-induced vibrations and mechanical wear |

| Applications | Heat exchangers, HVAC systems, turbine blades | Rotating machinery like rotors, fans, and shafts |

| Balancing Method | Controlling fluid flow or heat output for temperature uniformity | Adding/removing weights or material to achieve mass symmetry |

| Impact on System | Enhances thermal efficiency and component lifespan | Improves rotational stability and reduces noise |

| Measurement Tools | Thermocouples, infrared cameras, thermal sensors | Balancing machines, vibration analyzers, dynamic sensors |

| Key Challenge | Accurate heat flow distribution in complex geometries | Precise identification of imbalance magnitude and location |

Introduction to Balancing Methods

Thermal balancing and static balancing are essential techniques used to ensure the stability and efficiency of rotating machinery by minimizing vibrations and uneven load distribution. Thermal balancing involves compensating for temperature-induced material expansion and stress variations, whereas static balancing focuses on correcting mass distribution to prevent unbalanced forces during rotation. Both methods improve machine performance, reduce wear, and extend equipment lifespan through targeted interventions based on operational conditions.

What is Thermal Balancing?

Thermal balancing is the process of equalizing temperature distribution within a rotating component to prevent uneven expansion and reduce stress, enhancing operational stability and longevity. Unlike static balancing, which corrects mass distribution without accounting for temperature effects, thermal balancing specifically addresses thermal-induced imbalances caused by temperature gradients during machine operation. Proper thermal balancing is crucial in high-speed turbines, engines, and industrial fans where temperature variability can lead to vibration and mechanical failure.

What is Static Balancing?

Static balancing refers to the process of correcting uneven weight distribution in a rotating object to prevent it from wobbling when stationary. It involves placing the object on a horizontal plane and adding or removing weight at specific points to ensure its center of gravity aligns with its axis of rotation. Static balancing is crucial in applications like fans, rotors, and turbines to reduce vibration and increase operational stability.

Key Differences Between Thermal and Static Balancing

Thermal balancing addresses temperature-induced distortions in rotating components, ensuring even heat distribution to prevent imbalance caused by thermal expansion. Static balancing focuses on correcting uneven mass distribution by eliminating heavy spots in a stationary rotor to maintain equilibrium around a single axis. Unlike static balancing, thermal balancing is critical in high-speed or high-temperature applications where heat affects component geometry and performance.

Applications of Thermal Balancing

Thermal balancing is essential in applications involving high-speed rotating machinery like turbines, compressors, and electric motors, where uneven temperature distribution causes thermal expansion and distortion affecting performance. This method ensures components heat uniformly, reducing thermal stress and enhancing operational stability and efficiency. Static balancing, primarily used in low-speed rotating components such as fans and propellers, focuses on distributing mass evenly to prevent vibration but does not address heat-induced imbalances.

Applications of Static Balancing

Static balancing is crucial in applications where rotating components, such as fans, turbines, and automotive wheels, require precise weight distribution to prevent vibrations and enhance performance. This method ensures uniform mass distribution around a rotation axis, minimizing noise and wear in machinery like HVAC systems, electric motors, and industrial equipment. By maintaining equilibrium in static conditions, static balancing improves the longevity and efficiency of components operating at low to moderate speeds.

Advantages of Thermal Balancing

Thermal balancing ensures uniform temperature distribution across components, reducing thermal stress and enhancing the lifespan of rotating machinery. Compared to static balancing, it minimizes vibrations caused by uneven heat expansion, leading to smoother operation and improved efficiency. This method is critical in high-speed applications where temperature variations directly affect balance and performance.

Advantages of Static Balancing

Static balancing offers the advantage of simplifying maintenance by enabling easy detection and correction of weight distribution on a rotating object without the need for complex machinery. It improves operational efficiency by minimizing vibration and wear, leading to longer equipment lifespan and reduced downtime. Compared to thermal balancing, static balancing provides a quicker, cost-effective solution for ensuring smooth performance in applications like fans, rotors, and wheels.

Common Challenges in Both Balancing Methods

Thermal balancing and static balancing both face common challenges such as maintaining precise weight distribution to prevent vibration and uneven wear in rotating machinery. Achieving accurate measurements can be difficult due to factors like temperature fluctuations, material inconsistencies, and equipment limitations. These challenges often require advanced diagnostic tools and regular calibration to ensure consistent balancing performance and extended machinery lifespan.

Choosing the Right Balancing Technique

Choosing the right balancing technique depends on the application and operating conditions, with thermal balancing addressing temperature-induced distortions in rotating machinery, while static balancing targets uneven weight distribution at rest. Thermal balancing is crucial for turbines and high-speed rotors where thermal gradients cause shaft bending, ensuring operational stability and extending component life. Static balancing suits applications with simpler rotational speeds or where imbalance is primarily due to ununiform mass distribution, providing cost-effective correction without the need for complex thermal analysis.

Thermal balancing Infographic

libterm.com

libterm.com