Carbonitriding is a heat treatment process that diffuses both carbon and nitrogen into the surface of steel to enhance hardness, wear resistance, and fatigue strength. This method improves your component's durability by creating a hard, wear-resistant surface layer while maintaining a tough and ductile core. Discover how carbonitriding can optimize your materials by reading the rest of the article.

Table of Comparison

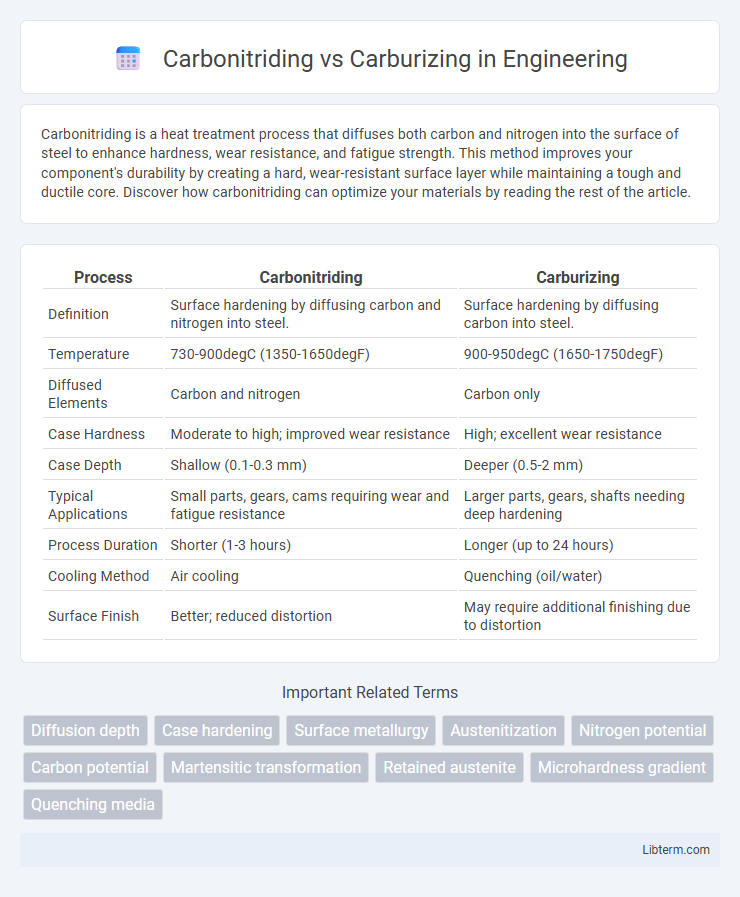

| Process | Carbonitriding | Carburizing |

|---|---|---|

| Definition | Surface hardening by diffusing carbon and nitrogen into steel. | Surface hardening by diffusing carbon into steel. |

| Temperature | 730-900degC (1350-1650degF) | 900-950degC (1650-1750degF) |

| Diffused Elements | Carbon and nitrogen | Carbon only |

| Case Hardness | Moderate to high; improved wear resistance | High; excellent wear resistance |

| Case Depth | Shallow (0.1-0.3 mm) | Deeper (0.5-2 mm) |

| Typical Applications | Small parts, gears, cams requiring wear and fatigue resistance | Larger parts, gears, shafts needing deep hardening |

| Process Duration | Shorter (1-3 hours) | Longer (up to 24 hours) |

| Cooling Method | Air cooling | Quenching (oil/water) |

| Surface Finish | Better; reduced distortion | May require additional finishing due to distortion |

Introduction to Surface Hardening Techniques

Carbonitriding and carburizing are advanced surface hardening techniques used to enhance the wear resistance and fatigue strength of steel components. Carbonitriding introduces both carbon and nitrogen into the steel surface, resulting in a hardened layer with improved corrosion resistance and reduced distortion compared to carburizing, which primarily diffuses carbon to form a hard, wear-resistant case. These processes are critical in automotive and industrial applications where increased surface durability extends component lifespan.

What is Carburizing?

Carburizing is a heat treatment process that introduces carbon into a steel surface by exposing the metal to a carbon-rich environment at high temperatures, typically between 850degC and 950degC. This process enhances surface hardness and wear resistance while maintaining a tougher, ductile core, making it ideal for components subjected to heavy wear and impact. Compared to carbonitriding, carburizing generally results in a deeper carbon diffusion depth, leading to a thicker hardened case suitable for large or heavily stressed parts.

What is Carbonitriding?

Carbonitriding is a heat treatment process that introduces both carbon and nitrogen into the surface layer of steel to enhance wear resistance, fatigue strength, and corrosion resistance. This method typically involves heating the steel in a controlled atmosphere containing ammonia and a carbon-rich gas at temperatures between 700-900degC. Compared to carburizing, carbonitriding produces a harder surface with improved dimensional stability and a thinner case depth, making it ideal for small components requiring enhanced surface properties.

Key Differences Between Carburizing and Carbonitriding

Carburizing involves diffusing carbon into the surface of steel at high temperatures, enhancing hardness and wear resistance primarily through carbon enrichment. Carbonitriding introduces both carbon and nitrogen to the steel surface, resulting in improved wear resistance, fatigue strength, and corrosion resistance due to the combined effects of nitrogen and carbon. The main differences lie in the process temperature, with carburizing typically performed at 900-950degC and carbonitriding at lower temperatures around 700-880degC, and the resulting case hardness and thickness, where carbonitriding produces a thinner, harder case with better fatigue properties.

Process Steps: Carburizing vs Carbonitriding

Carburizing involves heating steel in a carbon-rich environment to diffuse carbon into the surface, typically followed by quenching to form a hard case. Carbonitriding combines this process by introducing both carbon and nitrogen gases during heating, resulting in a thinner, harder case with improved wear resistance and fatigue strength. The nitrogen presence in carbonitriding creates a more uniform hardness profile and reduces distortion compared to carburizing.

Chemical and Microstructural Changes

Carbonitriding introduces both carbon and nitrogen into the steel surface, resulting in a hardened case with improved wear resistance and fatigue strength due to the formation of nitrides and carbonitrides along with austenite transformation. Carburizing primarily enriches the surface with carbon, producing a thick, carbon-saturated austenitic layer that transforms into martensite upon quenching, enhancing hardness and toughness. The simultaneous nitrogen diffusion in carbonitriding modifies the microstructure by refining grain size and precipitating carbonitrides, whereas carburizing mainly creates a carbon gradient without significant nitride formation.

Material Compatibility and Applications

Carbonitriding is suitable for low-carbon steels and alloy steels, enhancing surface hardness and wear resistance through the addition of both carbon and nitrogen, making it ideal for automotive components and small gears. Carburizing works best on low-carbon steel, enriching the surface with carbon to improve hardness and fatigue strength, commonly applied in heavy-duty gears, shafts, and bearings. Material compatibility in carbonitriding allows for faster processing times but requires careful control to prevent brittleness, while carburizing offers deeper case hardening suitable for components subjected to high stress.

Mechanical Properties Achieved

Carbonitriding enhances surface hardness and fatigue resistance by introducing both carbon and nitrogen, resulting in improved wear resistance and surface strength compared to carburizing alone. Carburizing primarily increases surface hardness and tensile strength by diffusing carbon into the steel, creating a hard, wear-resistant case while maintaining a tough core. The presence of nitrogen in carbonitriding also improves corrosion resistance and reduces distortion, making it ideal for components subjected to cyclic stresses and impact loading.

Cost Analysis and Industrial Considerations

Carbonitriding typically incurs lower costs than carburizing due to shorter process times and reduced furnace energy consumption, making it economically advantageous for high-volume production runs. Industrial considerations highlight carbonitriding's ability to achieve improved wear resistance and fatigue strength with minimal distortion, benefiting applications requiring fine, uniform case hardness. Carburizing remains preferred for deeper case depths and complex geometries despite higher costs associated with longer processing and post-treatment requirements.

Choosing the Right Process: Factors to Consider

Choosing between carbonitriding and carburizing depends on factors such as required surface hardness, wear resistance, and component application. Carbonitriding provides enhanced fatigue strength and corrosion resistance by introducing nitrogen alongside carbon, making it suitable for parts subjected to high stress and corrosive environments. Carburizing is preferred for achieving deeper hardening depth and higher case hardness, ideal for heavy-duty components requiring superior toughness.

Carbonitriding Infographic

libterm.com

libterm.com