Riveting captures attention through its compelling and intense nature, making any story or presentation unforgettable. Mastering the art of creating riveting content ensures your message resonates deeply with your audience. Explore the rest of the article to discover how to craft truly captivating narratives.

Table of Comparison

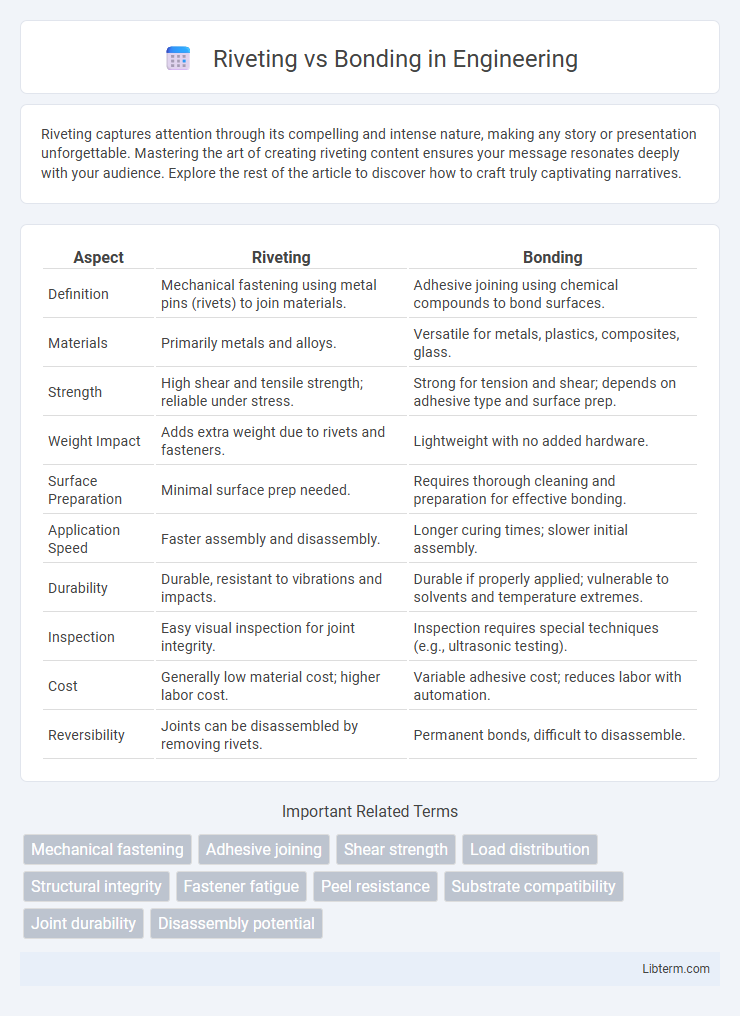

| Aspect | Riveting | Bonding |

|---|---|---|

| Definition | Mechanical fastening using metal pins (rivets) to join materials. | Adhesive joining using chemical compounds to bond surfaces. |

| Materials | Primarily metals and alloys. | Versatile for metals, plastics, composites, glass. |

| Strength | High shear and tensile strength; reliable under stress. | Strong for tension and shear; depends on adhesive type and surface prep. |

| Weight Impact | Adds extra weight due to rivets and fasteners. | Lightweight with no added hardware. |

| Surface Preparation | Minimal surface prep needed. | Requires thorough cleaning and preparation for effective bonding. |

| Application Speed | Faster assembly and disassembly. | Longer curing times; slower initial assembly. |

| Durability | Durable, resistant to vibrations and impacts. | Durable if properly applied; vulnerable to solvents and temperature extremes. |

| Inspection | Easy visual inspection for joint integrity. | Inspection requires special techniques (e.g., ultrasonic testing). |

| Cost | Generally low material cost; higher labor cost. | Variable adhesive cost; reduces labor with automation. |

| Reversibility | Joints can be disassembled by removing rivets. | Permanent bonds, difficult to disassemble. |

Introduction to Riveting and Bonding

Riveting involves mechanically fastening materials using metal pins called rivets, which create strong joints ideal for heavy-duty applications in aerospace and construction. Bonding uses adhesives to join surfaces, offering advantages like uniform stress distribution and the ability to bond dissimilar materials without adding weight. Both techniques provide distinct benefits depending on load requirements, material properties, and assembly conditions.

Understanding Riveting: Definition and Process

Riveting is a mechanical fastening process that involves joining two or more materials by inserting a metal pin called a rivet through pre-drilled holes and deforming its tail to hold the materials together. This technique ensures strong, permanent joints commonly used in industries such as aerospace, construction, and automotive manufacturing. The process provides high shear strength and resistance to vibration, making it ideal for structural applications where durability and reliability are critical.

Exploring Bonding: Definition and Methods

Bonding is a joining process that uses adhesives to create a strong, durable connection between materials by molecular attraction and mechanical interlocking. Common bonding methods include epoxy, polyurethane, acrylic, and cyanoacrylate adhesives, each suited for different substrates and environmental conditions. This method offers advantages like stress distribution, design flexibility, and compatibility with dissimilar materials compared to mechanical fastening techniques like riveting.

Material Compatibility in Riveting vs Bonding

Riveting provides strong mechanical fastening suitable for dissimilar materials such as metal to plastic or composites, ensuring high structural integrity without material degradation. Bonding relies on adhesive compatibility and surface preparation, which can limit its effectiveness with materials having incompatible surface energies or moisture sensitivity. Choosing riveting over bonding is critical when material combinations present challenges for adhesive curing or long-term durability in harsh environments.

Strength and Durability Comparison

Riveting provides mechanical fastening with high shear strength and excellent resistance to vibration, making it ideal for structural applications requiring durability under dynamic loads. Bonding, using adhesives, offers uniform stress distribution and excellent fatigue resistance, but its strength depends heavily on surface preparation and environmental conditions. While riveting ensures consistent mechanical interlocking, bonding excels in creating lightweight, corrosion-resistant joints with high tensile strength.

Installation and Application Differences

Riveting involves mechanical fastening by inserting metal pins through aligned holes in components and deforming the pin ends to secure parts, typically used in heavy-duty, load-bearing structures like aircraft and bridges. Bonding relies on adhesives that create a chemical or physical bond between surfaces, ideal for smooth, clean materials and applications requiring uniform stress distribution without added weight. Installation time for riveting is generally longer due to hole drilling and mechanical deformation, whereas bonding demands surface preparation and curing time, influencing their suitability based on application-specific strength, weight, and assembly speed requirements.

Cost Analysis: Riveting vs Bonding

Riveting typically incurs higher labor costs due to the manual installation process and the need for skilled workers, offset by low material expenses. Bonding, using advanced adhesives, often reduces labor time and associated costs but may require more expensive materials and surface preparation. Total cost analysis favors riveting in low-volume or repair scenarios, while bonding proves cost-effective in high-volume production with automation possibilities.

Pros and Cons of Riveting

Riveting offers strong mechanical fastening with high shear strength and reliability in heavy-duty applications but can add weight and require access to both sides of the materials being joined. It provides durability under vibration and stress but may lead to stress concentration and potential material deformation around the rivet holes. Installation speed and inspection are relatively straightforward, yet riveting lacks the flexibility and aesthetic smoothness provided by bonding methods.

Advantages and Drawbacks of Bonding

Bonding offers advantages such as improved stress distribution, reduced weight, and the ability to join dissimilar materials without causing deformation, making it ideal for complex assemblies and delicate substrates. However, drawbacks include sensitivity to surface preparation, potential decreased strength under environmental exposure like moisture and temperature fluctuations, and limited ability to disassemble joints compared to mechanical fastening methods like riveting. Proper adhesive selection and surface treatment are critical to ensuring durable, reliable bonded joints in industrial applications.

Choosing the Right Technique for Your Project

Selecting between riveting and bonding hinges on factors like material type, load requirements, and environmental conditions. Riveting offers strong mechanical fastening ideal for heavy-duty applications and metals, while bonding excels in distributing stress evenly and is suited for composites and lightweight materials. Understanding project-specific demands ensures optimal structural integrity and longevity by aligning technique capabilities with design goals.

Riveting Infographic

libterm.com

libterm.com