Precipitation hardening enhances the strength and hardness of metal alloys by forming fine particles within the metal matrix, which hinder dislocation movement. This process involves solution treatment, quenching, and aging to achieve optimal mechanical properties. Explore the full article to learn how precipitation hardening can improve your materials' performance.

Table of Comparison

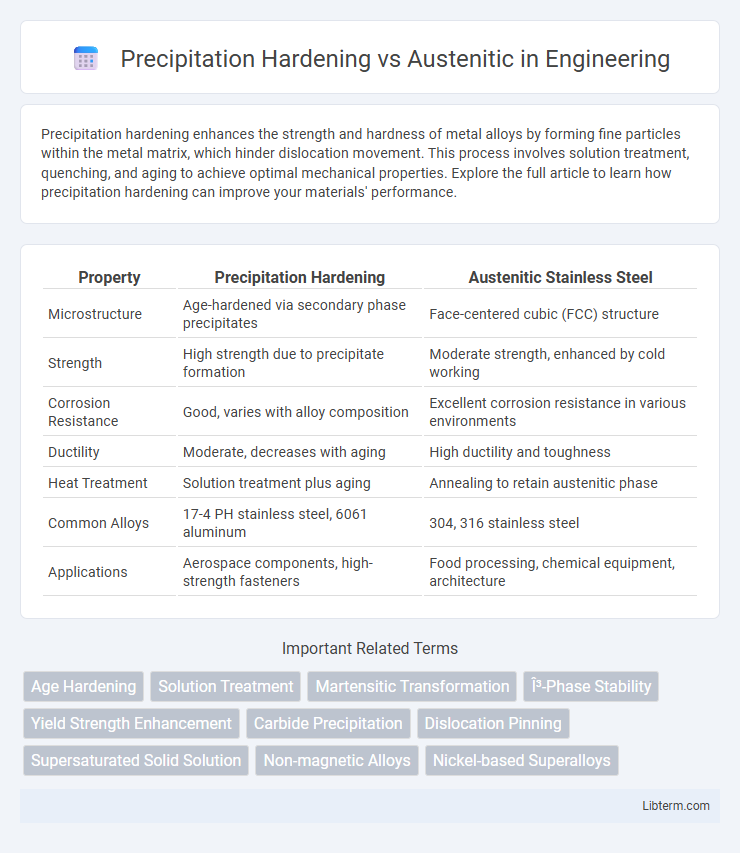

| Property | Precipitation Hardening | Austenitic Stainless Steel |

|---|---|---|

| Microstructure | Age-hardened via secondary phase precipitates | Face-centered cubic (FCC) structure |

| Strength | High strength due to precipitate formation | Moderate strength, enhanced by cold working |

| Corrosion Resistance | Good, varies with alloy composition | Excellent corrosion resistance in various environments |

| Ductility | Moderate, decreases with aging | High ductility and toughness |

| Heat Treatment | Solution treatment plus aging | Annealing to retain austenitic phase |

| Common Alloys | 17-4 PH stainless steel, 6061 aluminum | 304, 316 stainless steel |

| Applications | Aerospace components, high-strength fasteners | Food processing, chemical equipment, architecture |

Introduction to Precipitation Hardening and Austenitic Alloys

Precipitation hardening alloys increase strength through the formation of fine particles that impede dislocation movement, commonly used in aluminum, nickel, and titanium alloys. Austenitic alloys, primarily stainless steels with high chromium and nickel content, exhibit excellent corrosion resistance and toughness due to their face-centered cubic (FCC) crystal structure. Understanding the distinct microstructural mechanisms in precipitation hardening and austenitic alloys is essential for optimizing mechanical properties in aerospace, automotive, and medical applications.

Defining Precipitation Hardening: Mechanism and Applications

Precipitation hardening, also known as age hardening, involves the formation of finely dispersed particles within a metal matrix to enhance strength and hardness through a controlled heat treatment process. This mechanism impedes dislocation movement, making alloys like aluminum, titanium, and nickel-based superalloys ideal for aerospace, automotive, and structural applications. Contrastingly, austenitic steels, primarily composed of iron, chromium, and nickel, rely on a face-centered cubic crystal structure for corrosion resistance and ductility but do not undergo precipitation hardening significantly.

Understanding Austenitic Alloys: Structure and Properties

Austenitic alloys, characterized by a face-centered cubic (FCC) crystal structure, exhibit exceptional corrosion resistance and excellent toughness across a wide temperature range. Their non-magnetic nature and superior ductility make them ideal for applications in chemical processing and cryogenics, contrasting with precipitation hardening alloys that gain strength through controlled aging treatments. The inherent stability of the austenitic phase ensures mechanical consistency without the necessity for heat-induced precipitation, resulting in materials tailored for weldability and formability.

Composition Differences: Precipitation Hardening vs Austenitic

Precipitation hardening stainless steels contain elements like aluminum, titanium, or copper that form fine precipitates to enhance strength, while austenitic stainless steels primarily consist of high chromium and nickel content for corrosion resistance and toughness. Precipitation hardening alloys typically have lower nickel compared to austenitic grades but include aluminum or titanium to facilitate age hardening. Austenitic stainless steels generally lack the precipitation-enhancing elements found in precipitation hardening grades, focusing on a face-centered cubic (FCC) crystal structure stabilized by high nickel and chromium levels.

Mechanical Properties Comparison

Precipitation hardening alloys exhibit superior tensile strength and yield strength compared to austenitic stainless steels, due to the fine distribution of precipitates that hinder dislocation motion. Austenitic steels provide excellent ductility and toughness, making them better suited for applications requiring high formability and impact resistance. Corrosion resistance in austenitic stainless steels is generally higher, while precipitation hardened alloys excel in wear resistance and hardness because of their microstructural strengthening mechanisms.

Corrosion Resistance Analysis

Precipitation hardening stainless steels exhibit superior corrosion resistance due to the formation of finely dispersed precipitates that enhance passivation and prevent localized pitting. Austenitic stainless steels provide excellent overall corrosion resistance in various environments, mainly due to their high chromium and nickel content, which stabilizes the austenitic phase and forms a robust passive oxide layer. Comparative analysis shows precipitation-hardened grades like 17-4 PH perform better in chloride-rich environments, offering improved resistance to stress corrosion cracking compared to conventional austenitic grades such as 304 or 316.

Heat Treatment Processes for Each Alloy Type

Precipitation hardening alloys undergo specialized heat treatment involving solution treatment, quenching, and aging to form fine precipitates that significantly enhance strength and hardness. Austenitic alloys are typically solution treated to dissolve alloying elements, followed by rapid cooling to retain a stable face-centered cubic (FCC) structure, but they generally do not respond to traditional heat treatment for hardening. The heat treatment process for precipitation hardening grades, such as 17-4 PH stainless steel, is critical for optimizing mechanical properties, whereas austenitic grades like 304 and 316 stainless steels rely more on work hardening than thermal processes for strength enhancement.

Common Industrial Applications

Precipitation hardening alloys, such as Maraging steel and Aluminum-copper alloys, are widely used in aerospace, automotive, and medical implant industries for their exceptional strength and corrosion resistance. Austenitic stainless steels, primarily composed of high chromium and nickel content, are favored in chemical processing, food manufacturing, and construction due to their excellent ductility, toughness, and corrosion resistance. Both materials address specific industrial needs, with precipitation hardening alloys preferred for high-strength applications and austenitic steels chosen for environments demanding superior corrosion resistance and formability.

Advantages and Limitations of Each Approach

Precipitation hardening offers superior strength and hardness by introducing fine precipitates that impede dislocation motion, making it ideal for aerospace and automotive applications requiring high performance. Austenitic stainless steels provide excellent corrosion resistance and toughness due to their face-centered cubic structure and high chromium and nickel content, but they have lower strength compared to precipitation-hardened alloys. The limitation of precipitation hardening lies in its sensitivity to heat treatment parameters and reduced corrosion resistance, while austenitic steels can suffer from work hardening and lower yield strength, affecting structural applications under heavy load.

Selecting the Right Alloy: Key Considerations

Selecting the right alloy involves understanding the distinct mechanical properties and applications of precipitation hardening versus austenitic steels. Precipitation hardening alloys offer superior strength and hardness through heat treatment processes, making them ideal for aerospace and high-stress environments, while austenitic stainless steels provide excellent corrosion resistance and ductility suited for chemical processing and food industry applications. Key considerations include operating temperature, corrosion exposure, required strength, and ease of fabrication to ensure optimal performance and longevity.

Precipitation Hardening Infographic

libterm.com

libterm.com