National Pipe Thread (NPT) is a U.S. standard for tapered threads used to join pipes and fittings, ensuring a tight seal through the wedging action of the threads. This threading system is essential for preventing leaks in plumbing, gas, and hydraulic systems by providing reliable, pressure-tight connections. Explore this article to understand how NPT threading can improve the safety and efficiency of your piping projects.

Table of Comparison

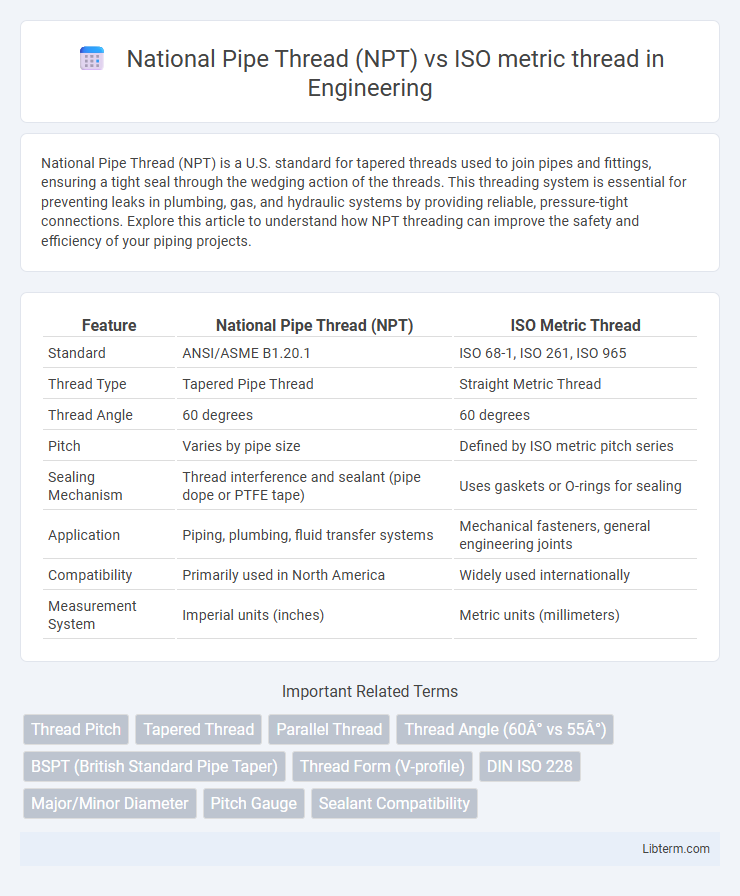

| Feature | National Pipe Thread (NPT) | ISO Metric Thread |

|---|---|---|

| Standard | ANSI/ASME B1.20.1 | ISO 68-1, ISO 261, ISO 965 |

| Thread Type | Tapered Pipe Thread | Straight Metric Thread |

| Thread Angle | 60 degrees | 60 degrees |

| Pitch | Varies by pipe size | Defined by ISO metric pitch series |

| Sealing Mechanism | Thread interference and sealant (pipe dope or PTFE tape) | Uses gaskets or O-rings for sealing |

| Application | Piping, plumbing, fluid transfer systems | Mechanical fasteners, general engineering joints |

| Compatibility | Primarily used in North America | Widely used internationally |

| Measurement System | Imperial units (inches) | Metric units (millimeters) |

Introduction to Thread Standards

National Pipe Thread (NPT) is a U.S. standard for tapered threads used primarily in piping and plumbing to create pressure-tight seals. ISO metric thread, standardized by the International Organization for Standardization, features a consistent profile with a 60-degree angle and is widely used in general mechanical engineering and manufacturing worldwide. Understanding these thread standards is essential for ensuring compatibility and reliability in mechanical assemblies and fluid systems.

What is National Pipe Thread (NPT)?

National Pipe Thread (NPT) is a U.S. standard for tapered threads used primarily on threaded pipes and fittings to create a tight, pressure-resistant seal. Characterized by its specific 60-degree thread angle and taper of 1 degree 47 minutes, NPT threads ensure leak-proof connections in plumbing and industrial applications. Unlike ISO metric threads that are straight and standardized globally, NPT threads rely on their taper to achieve sealing by wedging threads together under torque.

Understanding ISO Metric Threads

ISO metric threads follow international standards defined by ISO 68-1, characterized by a 60-degree thread angle and a symmetrical V-profile, which ensures reliable mechanical fastening and high compatibility across global industries. These threads are specified by their major diameter and pitch in millimeters, enhancing precision in manufacturing and facilitating standardized interchangeability in components such as bolts, nuts, and screws. Unlike NPT threads that are tapered and primarily used for sealing in fluid systems, ISO metric threads are parallel and designed for mechanical fastening without inherent sealing properties.

Key Differences Between NPT and ISO Metric Threads

National Pipe Thread (NPT) features a tapered profile designed for sealing pipes with a 60-degree thread angle, whereas ISO metric threads have a parallel profile with a 60-degree thread angle used primarily in mechanical fasteners. NPT threads rely on the taper to create a tight seal in fluid or gas systems, while ISO metric threads depend on additional sealing methods such as gaskets or O-rings due to their consistent diameter. The pitch and thread forms differ, with NPT threads measured in threads per inch (TPI) and ISO metric threads measured in millimeters, reflecting their distinct applications and standards.

Thread Geometry and Profile Comparison

National Pipe Thread (NPT) features a 60-degree thread angle with tapered profiles designed for sealing in fluid and gas applications, whereas ISO metric threads use a 60-degree thread angle with a constant diameter and a symmetrical, rounded profile optimized for mechanical fasteners. NPT threads have a tapered geometry creating interference fits that enhance sealing capability without additional sealing compounds, while ISO metric threads rely on precise fit and standardized pitch for mechanical strength and ease of assembly. The NPT's thread depth and flank clearance are tailored to prevent leaks under pressure, contrasting with the ISO metric's emphasis on consistent thread form for interchangeable fastening.

Applications of NPT vs ISO Metric Threads

National Pipe Thread (NPT) is primarily used in North American plumbing and piping systems for sealing pipes carrying liquids and gases due to its tapered design ensuring a tight seal. ISO metric threads dominate global manufacturing and automotive industries, providing standardized fasteners for machinery, electronics, and general mechanical assemblies with their cylindrical, parallel thread form. NPT threads excel in pressure-tight applications where fluid sealing is critical, while ISO metric threads are preferred for precision, interchangeability, and structural strength in mechanical joints.

Seal and Leakage Considerations

National Pipe Thread (NPT) utilizes a tapered thread design that creates a seal through the interference fit and thread deformation, often requiring thread sealants like PTFE tape to prevent leakage. ISO metric threads rely on a cylindrical thread profile, sealing primarily with an additional gasket or O-ring rather than the threads themselves. For applications demanding high leak resistance, NPT offers a reliable metal-to-metal seal when properly sealed, while ISO metric threads depend more heavily on secondary sealing elements to maintain leakage control.

Compatibility and Interchangeability Issues

National Pipe Thread (NPT) and ISO metric thread systems differ fundamentally in thread profile, angle, and dimensions, resulting in significant compatibility and interchangeability challenges. NPT uses a tapered thread with a 60-degree angle designed for sealing pipes, while ISO metric threads feature a parallel profile with a 60-degree angle suited for fastening components. Combining NPT with ISO metric threads often leads to leaks, mechanical failure, and compromised performance, necessitating specific adapters or conversion fittings for proper connection.

Installation and Maintenance Best Practices

National Pipe Thread (NPT) requires careful application of thread sealants or tapes during installation to ensure leak-proof joints, as its tapered thread design relies on sealants to fill gaps; regular inspection for wear and corrosion is essential to maintain integrity. ISO metric threads, characterized by their parallel profile and standardized pitch, demand precise torque application to avoid over-tightening or thread stripping during assembly, with maintenance focusing on periodic thread condition checks and lubrication. Selecting the appropriate thread type based on equipment specifications and adhering to proper installation torque and sealing protocols optimizes performance and extends service life.

Choosing the Right Thread Standard for Your Project

Choosing the right thread standard for your project depends on factors like compatibility, application, and regional preferences, with National Pipe Thread (NPT) commonly used for sealing pipes in North America and ISO metric threads favored globally for mechanical fastening. NPT features tapered threads providing a tight seal for fluid or gas systems, while ISO metric threads offer standardized dimensions suitable for precise mechanical assemblies and international interoperability. Assessing your project's requirements for sealing versus fastening and considering existing components ensures optimal performance and compliance with industry standards.

National Pipe Thread (NPT) Infographic

libterm.com

libterm.com