Forging is a manufacturing process that shapes metal using localized compressive forces, enhancing its strength and structural integrity. It is widely used in industries such as automotive, aerospace, and tool making to create durable components with superior mechanical properties. Discover how forging techniques can improve your products by exploring the details in the rest of this article.

Table of Comparison

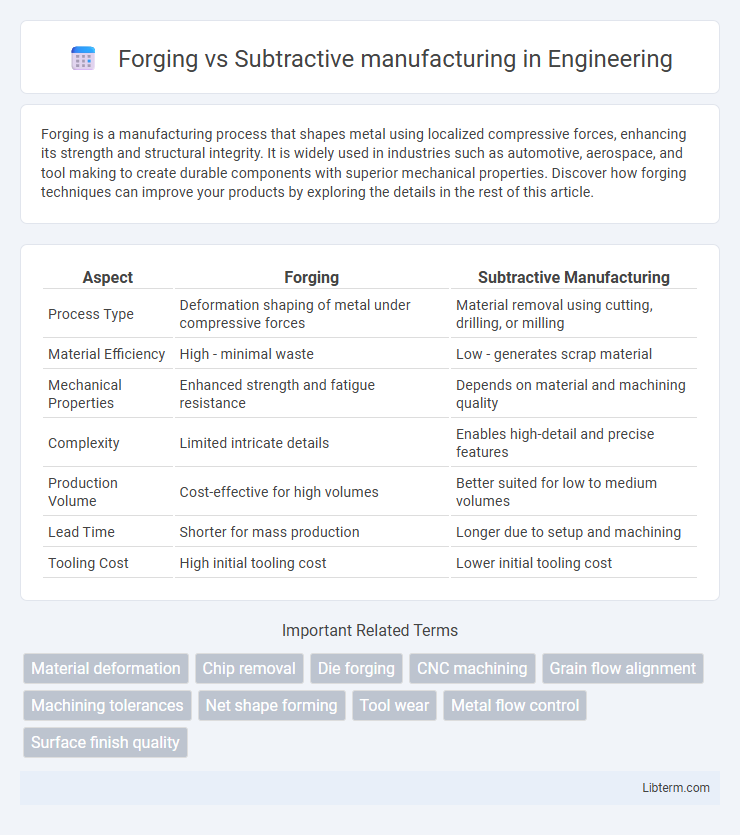

| Aspect | Forging | Subtractive Manufacturing |

|---|---|---|

| Process Type | Deformation shaping of metal under compressive forces | Material removal using cutting, drilling, or milling |

| Material Efficiency | High - minimal waste | Low - generates scrap material |

| Mechanical Properties | Enhanced strength and fatigue resistance | Depends on material and machining quality |

| Complexity | Limited intricate details | Enables high-detail and precise features |

| Production Volume | Cost-effective for high volumes | Better suited for low to medium volumes |

| Lead Time | Shorter for mass production | Longer due to setup and machining |

| Tooling Cost | High initial tooling cost | Lower initial tooling cost |

Introduction to Forging and Subtractive Manufacturing

Forging is a manufacturing process that shapes metal using compressive forces, often resulting in components with enhanced strength and structural integrity due to grain refinement. Subtractive manufacturing involves removing material from a raw workpiece through machining processes such as milling, turning, or drilling to achieve the desired geometry. Both techniques are fundamental in industrial production, with forging excelling in producing durable parts and subtractive methods offering high precision and complex geometries.

Key Differences Between Forging and Subtractive Manufacturing

Forging shapes metal through compressive forces applying heat and pressure, creating strong, dense parts with enhanced mechanical properties, while subtractive manufacturing removes material from a solid block using machining techniques like milling or turning, allowing precise and complex geometries. Forging is ideal for high-strength components in automotive and aerospace industries, offering superior grain structure and fatigue resistance, whereas subtractive manufacturing excels in flexibility and surface finish for prototypes and low-volume production. The key differences lie in material utilization, energy consumption, and resulting mechanical characteristics, with forging being more material-efficient but less versatile in detail compared to subtractive methods.

Process Overview: How Forging Works

Forging is a manufacturing process that shapes metal using localized compressive forces, typically delivered by a hammer or press. The metal is heated to a plastic state to improve malleability and then deformed into the desired shape within a die, resulting in enhanced mechanical properties due to grain refinement. This process contrasts with subtractive manufacturing, which removes material from a solid block, whereas forging forms parts by reshaping the material without material loss.

Process Overview: How Subtractive Manufacturing Works

Subtractive manufacturing operates by removing material from a solid block through processes like milling, turning, or drilling to achieve the desired shape and dimensions. CNC machines use computer-controlled cutting tools to precisely carve out complex geometries from metals, plastics, or composites, ensuring high accuracy and repeatability. This method contrasts with forging, which shapes metal through compressive forces, by focusing on material removal rather than deformation.

Material Suitability and Selection Criteria

Forging excels in processing metals like steel, aluminum, and titanium that benefit from enhanced grain structure and improved mechanical properties, making it ideal for high-strength applications. Subtractive manufacturing suits a wider range of materials, including plastics, composites, and metals such as aluminum and stainless steel, allowing precise dimensional control and complex geometries. Material selection hinges on factors like desired mechanical properties, part complexity, production volume, and cost efficiency, where forging favors durability and strength, while subtractive methods prioritize versatility and precision.

Mechanical Properties and Performance

Forging enhances mechanical properties such as tensile strength, fatigue resistance, and impact toughness by producing a dense, refined grain structure with fewer voids compared to subtractive manufacturing, which relies on cutting away material from a billet. Subtractive manufacturing can introduce stress concentrations and micro-cracks, potentially reducing fatigue life and performance under cyclic loading conditions. Forged components typically exhibit superior structural integrity and load-bearing capacity, making them ideal for high-stress applications like aerospace and automotive components.

Surface Finish and Dimensional Accuracy

Forging produces components with superior surface finish due to plastic deformation that refines grain structure, resulting in smoother surfaces and enhanced mechanical properties. Subtractive manufacturing achieves high dimensional accuracy by precisely removing material according to CAD models, but it may require additional finishing processes to improve surface quality. Combining forging's inherent surface integrity with subtractive machining can optimize both surface finish and dimensional precision in final parts.

Cost Considerations and Production Efficiency

Forging typically offers lower production costs for high-volume runs due to reduced material waste and faster cycle times compared to subtractive manufacturing, which involves significant material removal and longer processing durations. Subtractive manufacturing provides greater flexibility for complex, low-volume parts but incurs higher costs from tooling, material waste, and time-intensive machining processes. Forging enhances production efficiency through high repeatability and strength, while subtractive methods excel in precision and customization despite increased operational expenses.

Environmental Impact and Energy Consumption

Forging generally consumes less energy compared to subtractive manufacturing due to its near-net shape process, which reduces material waste and the need for extensive machining. Subtractive manufacturing involves removing material from a solid block, generating significant scrap and higher energy consumption during cutting and finishing operations. Forging's lower raw material waste and shorter production cycles contribute to a smaller environmental footprint and greater energy efficiency.

Choosing the Right Manufacturing Method for Your Application

Forging offers superior strength and durability by shaping metal through compressive forces, ideal for high-stress applications requiring enhanced mechanical properties. Subtractive manufacturing provides precise material removal from larger stock, suitable for complex geometries and tight tolerances in prototype or low-volume production. Selecting between forging and subtractive methods depends on factors like part complexity, required mechanical performance, production volume, and cost constraints to optimize manufacturing efficiency.

Forging Infographic

libterm.com

libterm.com