Elastic modulus quantifies a material's ability to resist deformation under stress, serving as a critical indicator of stiffness and mechanical performance. Understanding this property helps engineers and designers select suitable materials for applications requiring specific strength and flexibility levels. Explore the article to discover how elastic modulus impacts your material choices and design outcomes.

Table of Comparison

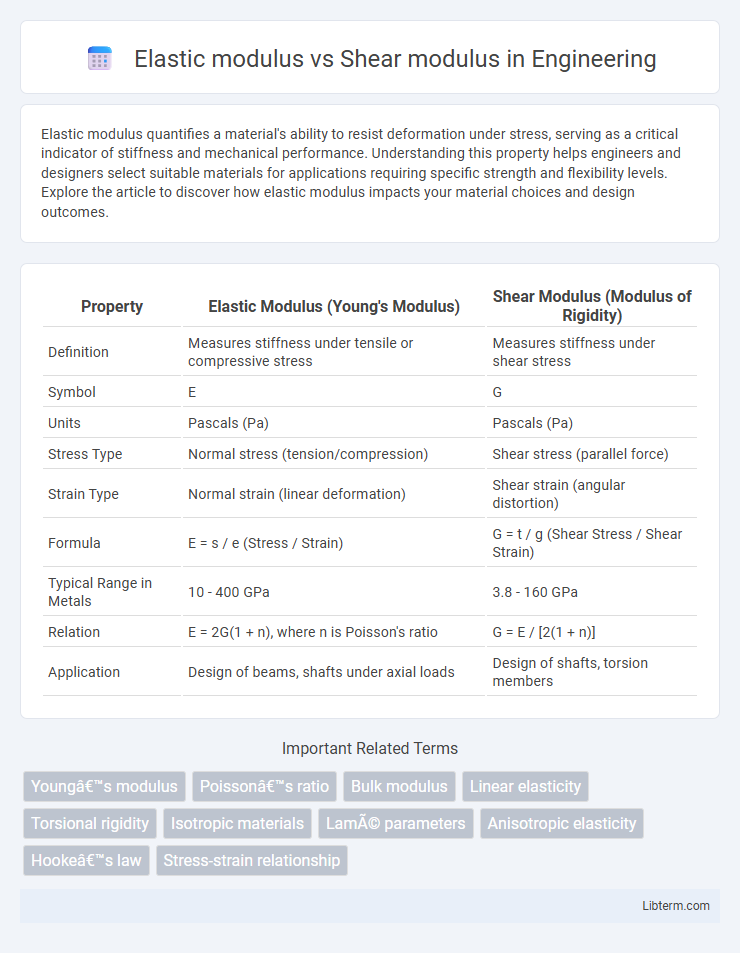

| Property | Elastic Modulus (Young's Modulus) | Shear Modulus (Modulus of Rigidity) |

|---|---|---|

| Definition | Measures stiffness under tensile or compressive stress | Measures stiffness under shear stress |

| Symbol | E | G |

| Units | Pascals (Pa) | Pascals (Pa) |

| Stress Type | Normal stress (tension/compression) | Shear stress (parallel force) |

| Strain Type | Normal strain (linear deformation) | Shear strain (angular distortion) |

| Formula | E = s / e (Stress / Strain) | G = t / g (Shear Stress / Shear Strain) |

| Typical Range in Metals | 10 - 400 GPa | 3.8 - 160 GPa |

| Relation | E = 2G(1 + n), where n is Poisson's ratio | G = E / [2(1 + n)] |

| Application | Design of beams, shafts under axial loads | Design of shafts, torsion members |

Introduction to Elastic Modulus and Shear Modulus

Elastic modulus, also known as Young's modulus, measures a material's ability to resist deformation under tensile or compressive stress, quantifying stiffness along the axis of applied force. Shear modulus, or modulus of rigidity, defines a material's response to shear stress, indicating how it deforms when subjected to forces causing adjacent layers to slide past each other. Both moduli are fundamental mechanical properties that characterize elastic behavior, with elastic modulus relating to longitudinal deformation and shear modulus addressing angular deformation.

Defining Elastic Modulus: Meaning and Importance

Elastic modulus, also known as Young's modulus, measures a material's ability to resist deformation under tensile or compressive stress, quantifying stiffness along a specific axis. It plays a crucial role in engineering applications by predicting how much a material will stretch or compress under load, which is essential for structural integrity. Unlike shear modulus, which describes resistance to shape changes under tangential forces, elastic modulus focuses on linear elasticity and material elongation behavior.

Understanding Shear Modulus: Key Concepts

Shear modulus, also known as the modulus of rigidity, measures a material's resistance to shear deformation and is defined as the ratio of shear stress to shear strain. Unlike the elastic modulus, which quantifies tensile or compressive stiffness, shear modulus specifically relates to shape changes without volume alteration. Understanding shear modulus is crucial in fields like materials science and mechanical engineering for predicting how materials behave under torsional forces.

Fundamental Differences: Elastic Modulus vs Shear Modulus

Elastic modulus measures a material's resistance to uniaxial tensile or compressive deformation, quantifying stiffness in stretching or compressing along one axis. Shear modulus, also known as the modulus of rigidity, quantifies resistance to shape changes under shear stress, reflecting stiffness in response to tangential forces. Fundamental differences lie in the modes of deformation each modulus characterizes: elastic modulus applies to linear extension or compression, while shear modulus applies to angular distortion.

Mathematical Expressions and Units

Elastic modulus (E) quantifies a material's stiffness under tensile or compressive stress, mathematically expressed as E = s / e, where s is normal stress (Pa) and e is strain (dimensionless). Shear modulus (G), also known as the modulus of rigidity, measures resistance to shear deformation, defined by G = t / g, with t representing shear stress (Pa) and g the shear strain (dimensionless). Both moduli share the same SI unit, pascal (Pa), indicating their role in characterizing different aspects of a material's elastic behavior.

Relationship Between Elastic Modulus and Shear Modulus

The relationship between elastic modulus (Young's modulus) and shear modulus is defined by the material's Poisson's ratio, which connects these two fundamental mechanical properties through the formula \( G = \frac{E}{2(1+\nu)} \). Elastic modulus measures the stiffness of a material under tensile or compressive loads, while shear modulus quantifies its response to shear stress. This intrinsic link enables engineers to predict material behavior under different loading conditions using one modulus if the other and Poisson's ratio are known.

Factors Affecting Elastic and Shear Moduli

Temperature fluctuations significantly impact both elastic modulus and shear modulus by altering atomic bonding forces within materials, leading to variations in stiffness and resistance to shear deformation. Material composition, including grain size, phase distribution, and impurity content, directly influences moduli by affecting crystallographic structure and dislocation movement. Furthermore, microstructural features such as defects, porosity, and processing history modify the elastic and shear moduli by changing the material's ability to store and dissipate mechanical energy.

Practical Applications in Engineering and Materials Science

Elastic modulus, also known as Young's modulus, measures a material's ability to resist deformation under tensile or compressive stress and is crucial for designing structural components like beams and columns in civil and mechanical engineering. Shear modulus quantifies a material's response to shear stress, essential for analyzing torsional behavior in shafts and mechanical fasteners, as well as predicting material performance in applications involving shear forces such as gears and riveted joints. Understanding the relationship between elastic and shear moduli enables engineers to select appropriate materials and design structures that optimize stiffness, strength, and durability in aerospace, automotive, and construction industries.

Measurement Methods and Testing Techniques

Elastic modulus is commonly measured through tensile testing, where a specimen is subjected to uniaxial stress and the resulting strain is recorded to determine stiffness. Shear modulus is typically evaluated using torsion tests, applying a twisting force to cylindrical samples to assess resistance to shear deformation. Ultrasonic testing methods also provide indirect measurements by analyzing wave propagation speeds related to both moduli in materials.

Summary Table: Elastic Modulus vs Shear Modulus

Elastic modulus (Young's modulus) measures a material's resistance to axial deformation under tensile or compressive stress, typically expressed in pascals (Pa), while shear modulus quantifies resistance to shape changes under shear stress. Elastic modulus relates normal stress to normal strain along the axis of loading, whereas shear modulus relates shear stress to shear strain, both critical in defining material stiffness. Key materials data show elastic modulus values are generally higher than shear modulus, with typical ratios around 2 to 3 for isotropic materials, reflecting different deformation mechanisms.

Elastic modulus Infographic

libterm.com

libterm.com