An intercooler enhances engine performance by cooling the air compressed by the turbocharger or supercharger, resulting in denser air entering the combustion chamber. This process improves combustion efficiency, increases power output, and reduces the risk of engine knocking. Discover how an intercooler can boost your vehicle's performance and why it's essential by reading the full article.

Table of Comparison

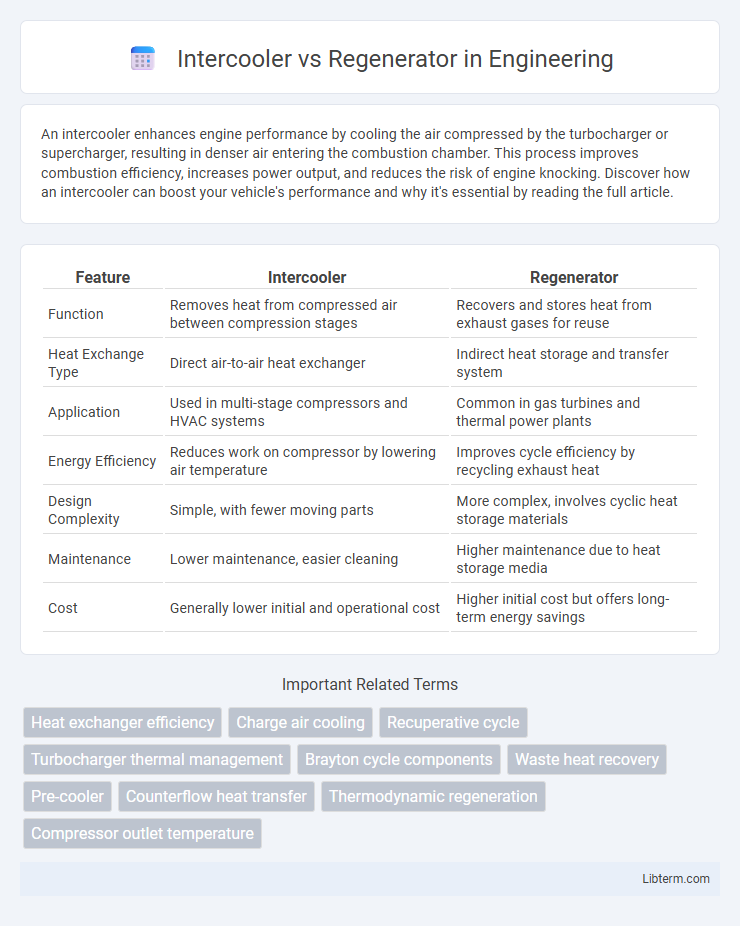

| Feature | Intercooler | Regenerator |

|---|---|---|

| Function | Removes heat from compressed air between compression stages | Recovers and stores heat from exhaust gases for reuse |

| Heat Exchange Type | Direct air-to-air heat exchanger | Indirect heat storage and transfer system |

| Application | Used in multi-stage compressors and HVAC systems | Common in gas turbines and thermal power plants |

| Energy Efficiency | Reduces work on compressor by lowering air temperature | Improves cycle efficiency by recycling exhaust heat |

| Design Complexity | Simple, with fewer moving parts | More complex, involves cyclic heat storage materials |

| Maintenance | Lower maintenance, easier cleaning | Higher maintenance due to heat storage media |

| Cost | Generally lower initial and operational cost | Higher initial cost but offers long-term energy savings |

Introduction to Intercoolers and Regenerators

Intercoolers and regenerators serve distinct functions in thermodynamic systems, primarily focusing on heat exchange efficiency. Intercoolers reduce the temperature of compressed air between compressor stages, enhancing engine performance and preventing overheating. Regenerators recover heat from exhaust gases to preheat incoming air or fuel, improving overall thermal efficiency in gas turbines and other industrial processes.

How Intercoolers Work

Intercoolers work by cooling the compressed air from turbochargers or superchargers before it enters the engine, increasing air density and improving combustion efficiency. They use either air-to-air or air-to-liquid heat exchangers to dissipate heat, reducing the temperature of the intake air and preventing engine knocking. In contrast, regenerators temporarily store heat from exhaust gases to preheat incoming air, aiming to recover and reuse thermal energy rather than directly cooling the compressed air.

How Regenerators Operate

Regenerators operate by cyclically storing heat from hot exhaust gases in a thermal storage medium and then transferring that heat to incoming compressed air during the next cycle, enhancing overall efficiency. This process involves alternating airflow paths through a fixed heat exchange matrix, which minimizes energy loss compared to continuous heat exchangers like intercoolers. The cyclic heat transfer mechanism in regenerators reduces fuel consumption and improves thermal efficiency in gas turbines and other heat engine systems.

Key Differences Between Intercooler and Regenerator

An intercooler cools compressed air between stages of a turbocharger or supercharger to increase engine efficiency, while a regenerator recovers waste heat from exhaust gases to preheat the incoming air or fuel, improving overall thermal efficiency. Intercoolers primarily reduce air temperature and increase density for better combustion, whereas regenerators focus on energy recovery to minimize fuel consumption. The key difference lies in their function: intercoolers act on airflow temperature during compression, whereas regenerators recycle thermal energy from exhaust gases.

Thermal Efficiency Comparison

Intercoolers and regenerators both enhance thermal efficiency in thermodynamic cycles by recovering heat, but they operate differently; intercoolers reduce the temperature of air between compression stages to decrease work input, while regenerators capture waste heat from exhaust gases to preheat incoming air, minimizing fuel consumption. Regenerators typically offer higher thermal efficiency in systems like gas turbines due to greater heat recovery potential, while intercoolers are more effective in multi-stage compressors by lowering compressor work. The choice between them depends on system design, operating conditions, and desired efficiency gains.

Applications in Industrial Systems

Intercoolers and regenerators serve critical roles in industrial systems by enhancing thermal efficiency and reducing energy consumption. Intercoolers are widely applied in gas compression processes to cool gases between compression stages, thereby improving compressor efficiency and protecting downstream equipment. Regenerators are employed in high-temperature industrial processes such as steel manufacturing and gas turbines to recover waste heat and transfer it back to the system, significantly lowering fuel consumption and operational costs.

Impact on Engine Performance

Intercoolers reduce intake air temperature, increasing air density and improving combustion efficiency, which boosts engine power and reduces thermal stress. Regenerators capture and reuse exhaust heat to preheat incoming air, enhancing fuel efficiency and lowering emissions by recovering waste heat. Both systems optimize engine performance by improving thermal management, but intercoolers prioritize power output while regenerators focus on fuel economy.

Cost and Maintenance Considerations

Intercoolers generally have lower upfront costs and simpler maintenance requirements due to their straightforward design and fewer moving parts, making them more cost-effective for many industrial applications. Regenerators involve higher initial investment and more complex upkeep because of their cyclic heat storage mechanisms and components subject to wear, potentially increasing long-term operational expenses. Evaluating the specific process demands and maintenance capabilities is crucial to determining the most economical choice between intercoolers and regenerators.

Advantages and Disadvantages Overview

Intercoolers enhance gas turbine efficiency by cooling compressed air between compressor stages, reducing work input and increasing power output, but they add weight and complexity to the system. Regenerators recover waste heat from exhaust gases to preheat the compressed air before combustion, improving thermal efficiency and fuel savings, though they require larger heat exchanger surfaces and can cause pressure losses. Selecting between intercoolers and regenerators depends on specific performance goals, space constraints, and operational priorities in gas turbine applications.

Which is Best: Intercooler or Regenerator?

Intercoolers and regenerators both improve thermal efficiency in gas turbine systems, but their effectiveness depends on specific operational goals and constraints. Intercoolers reduce the temperature of air between compression stages, leading to lower work required for compression, while regenerators recover waste heat from exhaust gases to preheat compressed air, significantly enhancing fuel efficiency. Choosing the best option involves evaluating factors such as application type, efficiency gains, installation costs, and maintenance requirements, with regenerators often preferred for continuous, high-temperature operations and intercoolers favored in systems prioritizing reduced compression work.

Intercooler Infographic

libterm.com

libterm.com