Lead time refers to the period between the initiation and completion of a process, crucial in production and supply chain management for efficient planning and customer satisfaction. Reducing lead time can significantly enhance your operational efficiency, decrease costs, and improve responsiveness to market demands. Explore the rest of this article to understand how optimizing lead time can transform your business outcomes.

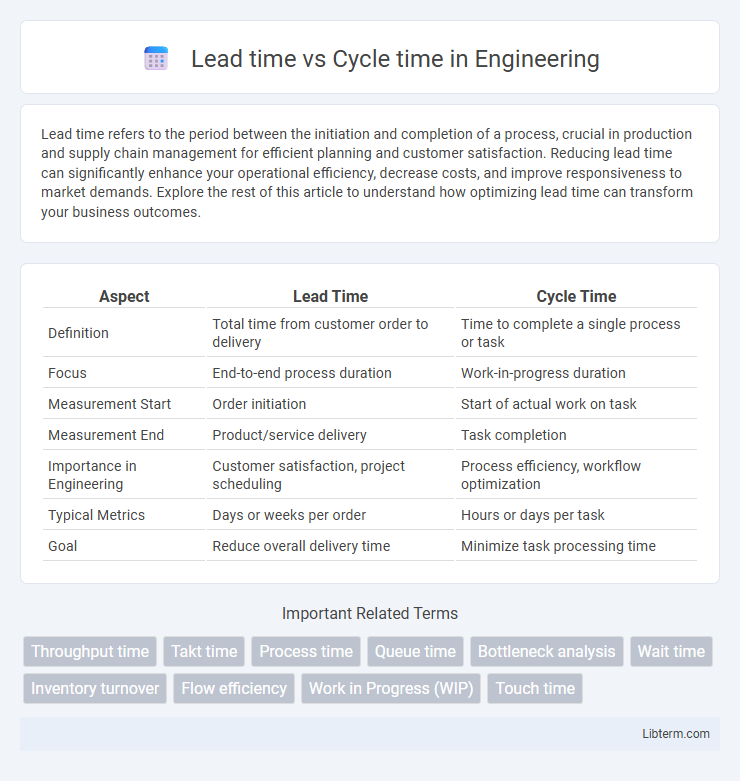

Table of Comparison

| Aspect | Lead Time | Cycle Time |

|---|---|---|

| Definition | Total time from customer order to delivery | Time to complete a single process or task |

| Focus | End-to-end process duration | Work-in-progress duration |

| Measurement Start | Order initiation | Start of actual work on task |

| Measurement End | Product/service delivery | Task completion |

| Importance in Engineering | Customer satisfaction, project scheduling | Process efficiency, workflow optimization |

| Typical Metrics | Days or weeks per order | Hours or days per task |

| Goal | Reduce overall delivery time | Minimize task processing time |

Introduction to Lead Time and Cycle Time

Lead time measures the total duration from the initiation of a request to its completion, encompassing all waiting and processing periods. Cycle time specifically tracks the active working time required to complete a task or production process, excluding delays or idle time. Understanding the distinction between lead time and cycle time helps improve workflow efficiency, optimize project management, and reduce delivery delays in manufacturing and software development.

Defining Lead Time

Lead time is the total duration from the initiation of a process or order to its completion, encompassing all waiting and processing times. It measures how long customers or stakeholders wait for a product or service from the moment a request is made until delivery. Accurately defining lead time helps businesses optimize production schedules, inventory management, and customer satisfaction by reducing delays and improving workflow efficiency.

Defining Cycle Time

Cycle time is the total duration required to complete a specific process or task from start to finish, measured in actual working time. It reflects the efficiency of production by tracking how long a single unit spends in the process, excluding waiting or idle periods. Understanding cycle time helps identify bottlenecks and optimize workflow for faster delivery and resource utilization.

Key Differences Between Lead Time and Cycle Time

Lead time measures the total duration from the initiation of a request to its delivery, capturing the entire process timeline including wait times, while cycle time specifically tracks the active working period required to complete a task or product phase. Lead time emphasizes customer perspectives by encompassing order receipt to fulfillment, whereas cycle time centers on internal efficiency by monitoring actual processing time. Understanding these distinctions aids in optimizing workflows and improving both delivery speed and operational productivity.

Importance in Project Management

Lead time and cycle time are critical metrics in project management that directly impact delivery efficiency and stakeholder satisfaction. Lead time measures the total duration from project initiation to completion, enabling managers to forecast deadlines and allocate resources effectively. Cycle time focuses on the actual work duration for individual tasks, helping identify bottlenecks and optimize workflow for continuous improvement.

Measuring Lead Time and Cycle Time

Measuring lead time involves tracking the total duration from the moment a customer places an order until the product or service is delivered, highlighting customer wait times and process efficiency. Cycle time measurement focuses on the actual working time taken to complete a specific task or process within the production or development cycle, emphasizing team productivity and process speed. Accurate data collection for both lead time and cycle time enables businesses to identify bottlenecks, optimize workflows, and improve overall operational performance.

Factors Affecting Lead Time and Cycle Time

Lead time and cycle time are influenced by factors such as process complexity, resource availability, and task dependencies. Variability in demand and workflow interruptions directly increase lead time, while inefficiencies in specific tasks primarily extend cycle time. Streamlining production stages, optimizing resource allocation, and minimizing delays help reduce both lead time and cycle time effectively.

Best Practices for Reducing Lead Time and Cycle Time

Reducing lead time and cycle time requires implementing lean methodologies such as value stream mapping to identify bottlenecks and eliminate waste in processes. Utilizing continuous integration and automation tools accelerates workflows by minimizing manual tasks and errors. Regular cross-functional collaboration ensures prompt issue resolution, optimizing throughput and enhancing overall efficiency.

Real-World Applications in Industries

Lead time and cycle time are critical metrics in manufacturing and software development, where lead time measures the total duration from order placement to delivery, while cycle time captures the actual time spent on production or processing. In supply chain management, optimizing lead time enhances customer satisfaction by reducing wait times, whereas minimizing cycle time improves operational efficiency and throughput. Industries such as automotive and electronics leverage these metrics to balance inventory levels and accelerate time-to-market for competitive advantage.

Conclusion: Choosing the Right Metric

Choosing the right metric between lead time and cycle time depends on the specific goals of your process analysis. Lead time measures the total duration from request to delivery, ideal for assessing customer experience and end-to-end efficiency. Cycle time focuses on the active working period, providing insight into the internal workflow and opportunities for process improvement.

Lead time Infographic

libterm.com

libterm.com