Operating speed directly impacts the efficiency and performance of machinery, influencing productivity and energy consumption. Understanding how to optimize your operating speed can lead to significant improvements in output quality and equipment longevity. Explore the rest of the article to learn practical strategies for maximizing your operating speed effectively.

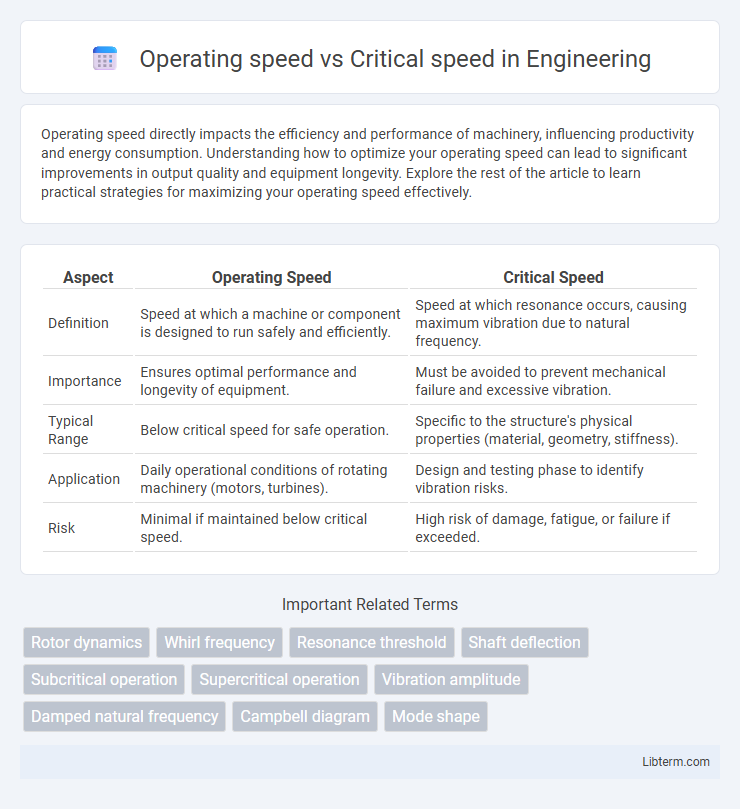

Table of Comparison

| Aspect | Operating Speed | Critical Speed |

|---|---|---|

| Definition | Speed at which a machine or component is designed to run safely and efficiently. | Speed at which resonance occurs, causing maximum vibration due to natural frequency. |

| Importance | Ensures optimal performance and longevity of equipment. | Must be avoided to prevent mechanical failure and excessive vibration. |

| Typical Range | Below critical speed for safe operation. | Specific to the structure's physical properties (material, geometry, stiffness). |

| Application | Daily operational conditions of rotating machinery (motors, turbines). | Design and testing phase to identify vibration risks. |

| Risk | Minimal if maintained below critical speed. | High risk of damage, fatigue, or failure if exceeded. |

Understanding Operating Speed and Critical Speed

Operating speed refers to the actual velocity at which a mechanical system or machine component operates during normal conditions, ensuring efficient performance without causing damage. Critical speed is the rotational speed at which the system's natural frequency coincides with the excitation frequency, leading to resonance and potentially damaging vibrations. Understanding the relationship between operating speed and critical speed is essential for designing machinery that avoids resonance and maintains stability during operation.

Defining Operating Speed in Mechanical Systems

Operating speed in mechanical systems refers to the consistent rotational velocity at which a machine or component functions during normal operation, typically measured in revolutions per minute (RPM). It is carefully selected to optimize performance and avoid mechanical resonances that occur at the critical speed, where the system's natural frequency matches the rotational frequency, causing excessive vibration and potential damage. Maintaining operating speed below the critical speed ensures system stability, reliability, and longevity in applications such as turbines, rotors, and shafts.

What is Critical Speed?

Critical speed refers to the rotational speed at which a rotating shaft or rotor experiences resonance, causing excessive vibration and potential structural failure. It occurs when the operating speed matches the natural frequency of the system, leading to dynamic instability. Understanding the critical speed is essential for designing machinery to ensure operating speeds remain below this threshold to avoid damage.

The Science Behind Rotational Dynamics

Operating speed refers to the rotational velocity at which a machine or rotor normally functions, typically below the critical speed to ensure stability and safety. Critical speed is the specific rotational speed at which the system's natural frequency matches the rotational frequency, causing resonance and potentially destructive vibrations. Understanding the interplay between operating speed and critical speed is essential in rotational dynamics to prevent structural failure and optimize mechanical performance.

Factors Influencing Operating Speed

Operating speed in rotating machinery is influenced by factors such as load conditions, material properties, and the design rigidity, which affect the safe and efficient performance of the equipment. Critical speed, defined as the rotational speed at which resonance occurs, depends primarily on shaft geometry, stiffness, and mass distribution. Optimizing operating speed below the critical speed threshold prevents excessive vibration and potential mechanical failure.

Determining Critical Speed in Machinery

Determining critical speed in machinery involves calculating the rotational speed at which the system's natural frequency matches the excitation frequency, causing resonance and excessive vibration. This speed depends on factors such as shaft stiffness, mass distribution, and bearing support, requiring precise modeling and analysis to ensure safe operation. Accurate critical speed determination prevents mechanical failure by guiding the design and operational limits below or above this threshold.

Risks of Operating Near Critical Speed

Operating near the critical speed of rotating machinery increases the risk of excessive vibrations that can lead to mechanical failure and reduced component lifespan. Resonance at critical speed intensifies stress on bearings, shafts, and mounts, potentially causing fatigue cracks and catastrophic breakdowns. Precise monitoring and control are essential to avoid operating conditions that approach or match critical speed, ensuring safety and equipment reliability.

Methods to Calculate Critical Speed

Critical speed is calculated using methods such as the Dunkerley's equation, which combines individual natural frequencies of shaft segments, and the Rayleigh-Ritz method, employing energy principles for approximate values. Finite Element Analysis (FEA) offers a numerical approach to accurately determine critical speed by modeling shaft dynamics under various boundary conditions. Operating speed must remain below critical speed to avoid resonance and ensure stable performance in rotating machinery.

Strategies to Avoid Critical Speed Failures

Operating speed must be carefully managed to remain below the critical speed, where resonance vibrations can cause system failure. Strategies to avoid critical speed failures include increasing shaft stiffness, reducing rotating mass, and implementing damping mechanisms to minimize vibration amplitude near resonance. Advanced predictive maintenance and finite element analysis enable accurate identification of critical speeds and timely adjustments to operating parameters.

Best Practices for Safe Operating Speed Management

Maintaining operating speed below the critical speed of rotating equipment is essential to prevent resonant vibrations and mechanical failures. Employ vibration analysis and real-time monitoring systems to detect early signs of imbalance or resonance near critical speeds. Implement regular maintenance schedules and engineer speed limits based on manufacturer specifications and dynamic balancing results to ensure safe and efficient operation.

Operating speed Infographic

libterm.com

libterm.com