Ductility refers to a material's ability to undergo significant plastic deformation before rupture, a critical factor in engineering and construction applications. Materials with high ductility, such as metals like copper and aluminum, can absorb energy and withstand stress without fracturing, ensuring structural integrity and safety. Explore the rest of this article to learn how ductility impacts material selection and performance in your projects.

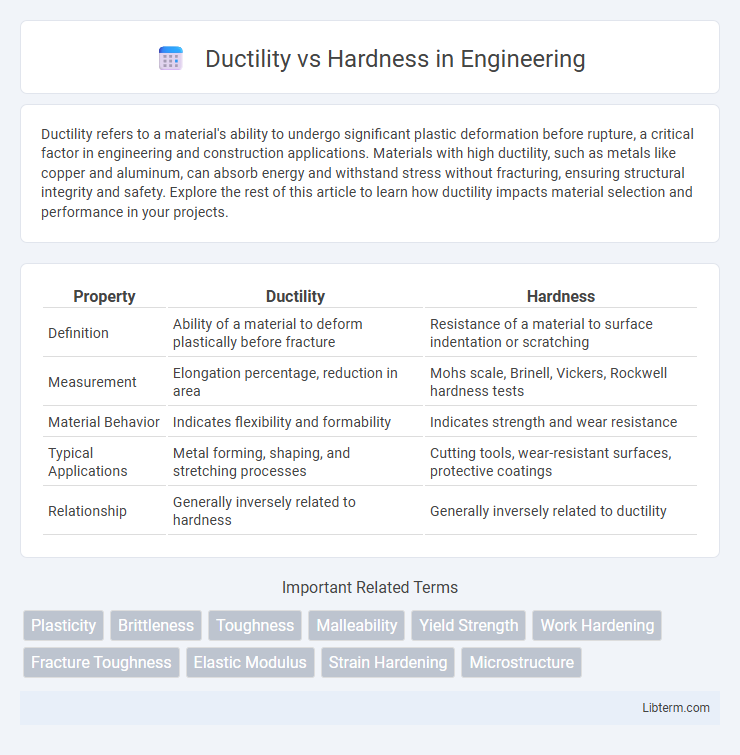

Table of Comparison

| Property | Ductility | Hardness |

|---|---|---|

| Definition | Ability of a material to deform plastically before fracture | Resistance of a material to surface indentation or scratching |

| Measurement | Elongation percentage, reduction in area | Mohs scale, Brinell, Vickers, Rockwell hardness tests |

| Material Behavior | Indicates flexibility and formability | Indicates strength and wear resistance |

| Typical Applications | Metal forming, shaping, and stretching processes | Cutting tools, wear-resistant surfaces, protective coatings |

| Relationship | Generally inversely related to hardness | Generally inversely related to ductility |

Understanding Ductility: Definition and Significance

Ductility is the ability of a material to undergo significant plastic deformation before fracture, measured by its elongation or reduction in area during a tensile test. This property is crucial for applications requiring materials to absorb energy and deform without breaking, such as in metal forming and structural components. Understanding ductility helps engineers select materials that balance flexibility and strength, optimizing performance and safety in construction and manufacturing.

What is Hardness? Key Concepts Explained

Hardness refers to a material's resistance to deformation, particularly permanent indentation, scratching, or abrasion, measured by tests such as Mohs, Brinell, or Rockwell scales. It indicates how well a material can withstand surface wear and is crucial for applications requiring durability and resistance to mechanical damage. While hardness emphasizes surface strength, it often inversely correlates with ductility, which describes a material's ability to deform plastically without breaking.

The Science Behind Ductility and Hardness

Ductility measures a material's ability to undergo plastic deformation without fracture, reflecting its capacity to stretch or bend under tensile stress. Hardness quantifies resistance to surface indentation or abrasion, indicating the material's strength against localized plastic deformation. The atomic structure and bonding influence both properties, where ductile metals have a more malleable crystal lattice allowing dislocation movement, while hardness increases with stronger bonds and reduced dislocation mobility.

Factors Affecting Ductility in Materials

Ductility in materials is influenced primarily by factors such as temperature, strain rate, and material composition, where higher temperatures generally enhance ductility by enabling atomic mobility. The presence of impurities and alloying elements can restrict dislocation movement, thus reducing ductility while increasing hardness. Microstructural features like grain size also play a crucial role; finer grains tend to increase strength and hardness but may decrease ductility due to limited slip systems.

Factors Influencing Hardness in Materials

Hardness in materials is primarily influenced by factors such as composition, microstructure, and heat treatment processes. Alloying elements like carbon in steel increase hardness by forming harder phases and impeding dislocation motion. Grain size refinement and work hardening through mechanical deformation also significantly enhance material hardness by restricting plastic deformation.

Ductility vs Hardness: Key Differences

Ductility measures a material's ability to deform plastically without breaking, while hardness indicates resistance to surface indentation or abrasion. Higher ductility often correlates with lower hardness, as materials that deform easily tend to be less resistant to surface wear. Understanding the trade-off between ductility and hardness is crucial for selecting materials in applications requiring flexibility versus those needing durability and wear resistance.

Testing Methods for Measuring Ductility

Ductility is commonly measured using tensile tests that record elongation and reduction in area as key indicators of a material's ability to deform plastically before fracture. Bend tests and hardness tests, while primarily assessing strength and resistance to deformation, can provide indirect insights into ductility by evaluating material behavior under stress. Charpy impact tests also contribute valuable data by showing how materials absorb energy during fracture, correlating with ductility in various conditions.

Techniques for Assessing Hardness

Techniques for assessing hardness include the Rockwell, Vickers, and Brinell tests, each measuring resistance to indentation under specific loads and indenter shapes. Rockwell hardness testing provides rapid results by determining the depth of penetration, while Vickers hardness uses a diamond pyramid indenter to assess small and thin materials with high precision. Brinell hardness testing applies a hardened steel or carbide ball to evaluate coarse materials and castings, offering insights into material resistance to deformation versus ductility.

Industrial Applications: When to Prioritize Ductility or Hardness

Industrial applications requiring metal forming, shaping, or bending prioritize ductility to avoid material failure and ensure flexibility during processes such as deep drawing and extrusion. Hardness becomes critical in wear-resistant environments like cutting tools, bearings, and surface coatings, where resistance to abrasion and deformation is essential. Selecting materials involves balancing ductility for impact absorption and hardness for durability, depending on operational demands and mechanical stresses.

Choosing the Right Material: Ductility and Hardness Balancing

Choosing the right material involves balancing ductility and hardness to meet specific application requirements. Materials with high ductility, such as pure metals like copper and aluminum, offer excellent deformation capabilities without fracturing, ideal for applications needing flexibility and toughness. In contrast, materials with high hardness, such as hardened steel or ceramics, provide superior wear resistance and strength but are more brittle, so engineers must carefully assess the trade-off between flexibility and brittleness to optimize performance in structural or mechanical components.

Ductility Infographic

libterm.com

libterm.com