Corrosion is a natural process causing the gradual destruction of metals through chemical reactions with their environment, often resulting in rust and structural damage. Preventing corrosion involves applying protective coatings, using corrosion-resistant materials, and controlling environmental factors such as humidity and pollutants. Discover effective strategies to safeguard your assets and extend their lifespan by reading the full article.

Table of Comparison

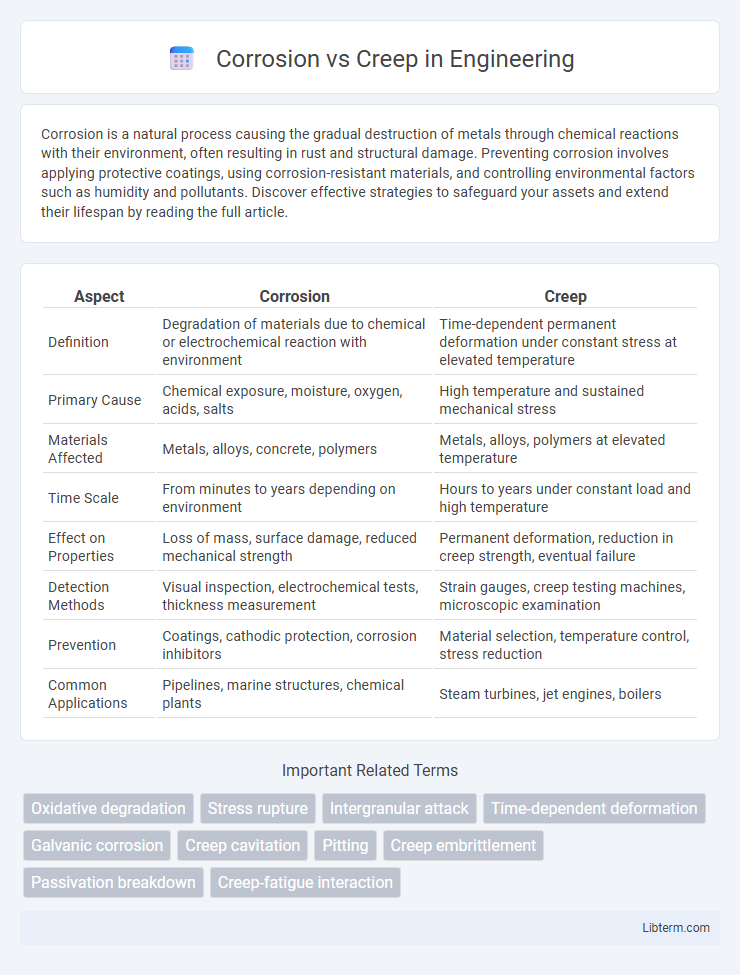

| Aspect | Corrosion | Creep |

|---|---|---|

| Definition | Degradation of materials due to chemical or electrochemical reaction with environment | Time-dependent permanent deformation under constant stress at elevated temperature |

| Primary Cause | Chemical exposure, moisture, oxygen, acids, salts | High temperature and sustained mechanical stress |

| Materials Affected | Metals, alloys, concrete, polymers | Metals, alloys, polymers at elevated temperature |

| Time Scale | From minutes to years depending on environment | Hours to years under constant load and high temperature |

| Effect on Properties | Loss of mass, surface damage, reduced mechanical strength | Permanent deformation, reduction in creep strength, eventual failure |

| Detection Methods | Visual inspection, electrochemical tests, thickness measurement | Strain gauges, creep testing machines, microscopic examination |

| Prevention | Coatings, cathodic protection, corrosion inhibitors | Material selection, temperature control, stress reduction |

| Common Applications | Pipelines, marine structures, chemical plants | Steam turbines, jet engines, boilers |

Understanding Corrosion: Definition and Mechanisms

Corrosion is the electrochemical or chemical degradation of metals caused by environmental interactions, leading to material loss or structural damage. It involves mechanisms such as oxidation-reduction reactions, where metal atoms lose electrons and form oxides or other compounds, often accelerated by factors like moisture, oxygen, and salts. Understanding corrosion requires analyzing the specific environmental conditions and material properties that influence rates and types, including uniform corrosion, pitting, galvanic corrosion, and stress corrosion cracking.

Fundamentals of Creep: What It Is and How It Occurs

Creep is the time-dependent, permanent deformation of materials under constant stress, typically occurring at high temperatures relative to a material's melting point. It involves three stages: primary (decreasing creep rate), secondary (steady-state creep), and tertiary (accelerating creep leading to failure), driven by mechanisms such as dislocation movement and diffusion. Unlike corrosion, which is chemical degradation, creep is a mechanical process influenced by temperature, stress, and microstructure changes in metals and alloys.

Key Differences Between Corrosion and Creep

Corrosion is the chemical or electrochemical reaction between a material, usually metal, and its environment leading to material degradation, while creep is the time-dependent plastic deformation of a material under constant stress, often at high temperature. Corrosion primarily affects the surface by causing material loss or surface damage, whereas creep affects the internal structure, leading to elongation or permanent deformation without immediate material loss. The key difference lies in corrosion being a chemical process dependent on environmental factors, and creep being a mechanical process influenced by stress and temperature.

Causes and Contributing Factors for Corrosion

Corrosion primarily occurs due to electrochemical reactions between a metal and its environment, involving factors such as moisture, oxygen, temperature, and the presence of corrosive agents like salts or acids. The rate of corrosion is influenced by environmental conditions including pH levels, humidity, and the presence of pollutants or microbial activity. Material composition, protective coatings, and exposure to aggressive chemicals also significantly contribute to the onset and progression of corrosion.

Conditions That Lead to Material Creep

Material creep occurs primarily under conditions of high temperature and sustained mechanical stress, often above 0.4 times the melting point of the material in Kelvin. Corrosion accelerates creep by causing surface degradation that acts as stress concentrators, particularly in aggressive environments with moisture, oxygen, or chemical agents. Common industries facing creep-related failures include power plants, aerospace, and petrochemical sectors where elevated temperatures and corrosive atmospheres coexist.

Effects of Corrosion on Material Performance

Corrosion significantly diminishes material performance by accelerating surface degradation, reducing mechanical strength, and increasing brittleness, which compromises structural integrity and lifespan. It promotes localized damage such as pitting and cracking that serves as initiation points for failure under stress. As a result, corrosion enhances vulnerability to creep deformation by weakening the microstructure and facilitating accelerated creep rates under high temperature and stress conditions.

Impact of Creep on Structural Integrity

Creep significantly impacts structural integrity by causing permanent deformation under sustained high stress and temperature, which weakens material strength over time. This progressive deformation can lead to micro-cracking and eventual failure, particularly in metal components used in high-temperature environments such as turbines and boilers. Unlike corrosion, which primarily affects surface material, creep compromises the internal structure, reducing load-bearing capacity and increasing the risk of catastrophic failure.

Detection and Measurement Techniques for Corrosion and Creep

Detection and measurement techniques for corrosion primarily include ultrasonic testing, radiography, and electrochemical methods such as corrosion potential monitoring and linear polarization resistance to quantify metal loss and monitor corrosion rates. In contrast, creep detection relies on deformation measurement techniques like extensometry, strain gauges, and creep testing machines that measure strain over time under constant load and temperature conditions. Advanced methods such as acoustic emission monitoring and digital image correlation provide real-time data for both corrosion-induced damage and creep deformation in critical materials.

Prevention and Control Methods for Corrosion and Creep

Corrosion prevention involves methods such as applying protective coatings, using corrosion-resistant alloys, and implementing cathodic protection systems to inhibit electrochemical reactions. Creep control relies on selecting materials with high creep resistance, optimizing operating temperatures and stresses, and employing heat treatment processes to enhance material strength. Regular inspection and maintenance further ensure early detection and mitigation of both corrosion and creep damage in industrial components.

Real-World Applications: Case Studies Comparing Corrosion and Creep

Corrosion significantly impacts infrastructure in marine environments, as demonstrated by the accelerated degradation of steel offshore platforms, while creep predominantly affects components in high-temperature power plants, leading to deformation and potential failure of turbine blades. Case studies from the oil and gas industry reveal corrosion-induced pipeline leaks causing costly shutdowns, contrasting with aerospace applications where creep-induced deformation in jet engine parts necessitates frequent inspections and material upgrades. These real-world examples highlight the critical need for tailored material selection and maintenance strategies to mitigate the distinct challenges posed by corrosion and creep in various industrial sectors.

Corrosion Infographic

libterm.com

libterm.com