Fracture toughness measures a material's ability to resist crack propagation, playing a critical role in determining its durability and safety under stress. Understanding this property is essential for selecting appropriate materials in engineering, construction, and manufacturing applications where failure prevention is crucial. Explore the rest of the article to discover how fracture toughness influences material performance and application.

Table of Comparison

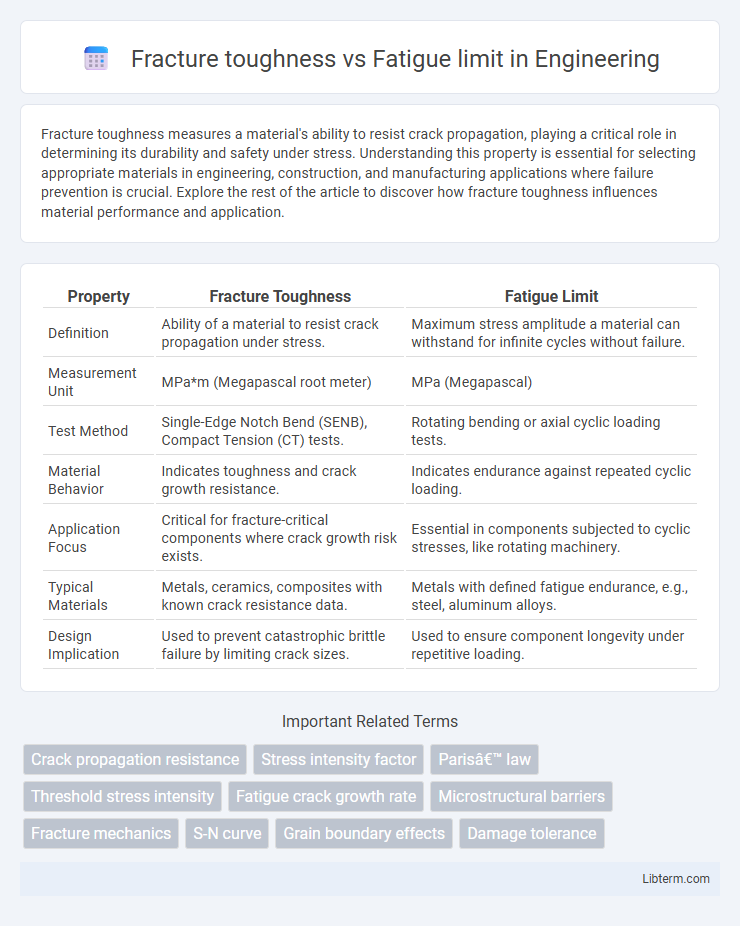

| Property | Fracture Toughness | Fatigue Limit |

|---|---|---|

| Definition | Ability of a material to resist crack propagation under stress. | Maximum stress amplitude a material can withstand for infinite cycles without failure. |

| Measurement Unit | MPa*m (Megapascal root meter) | MPa (Megapascal) |

| Test Method | Single-Edge Notch Bend (SENB), Compact Tension (CT) tests. | Rotating bending or axial cyclic loading tests. |

| Material Behavior | Indicates toughness and crack growth resistance. | Indicates endurance against repeated cyclic loading. |

| Application Focus | Critical for fracture-critical components where crack growth risk exists. | Essential in components subjected to cyclic stresses, like rotating machinery. |

| Typical Materials | Metals, ceramics, composites with known crack resistance data. | Metals with defined fatigue endurance, e.g., steel, aluminum alloys. |

| Design Implication | Used to prevent catastrophic brittle failure by limiting crack sizes. | Used to ensure component longevity under repetitive loading. |

Introduction to Fracture Toughness and Fatigue Limit

Fracture toughness measures a material's ability to resist crack propagation under stress, crucial for assessing structural integrity in brittle materials. Fatigue limit defines the maximum cyclic stress a material can endure indefinitely without failure, essential for predicting lifespan in components subjected to repetitive loading. Understanding both properties allows engineers to design materials that optimize resistance to sudden fracture and cyclic fatigue, enhancing safety and durability.

Defining Fracture Toughness: Key Concepts

Fracture toughness measures a material's ability to resist crack propagation under stress, quantified by the critical stress intensity factor (K_IC). It is a fundamental property in fracture mechanics, emphasizing the resistance to crack growth in presence of flaws. Unlike fatigue limit, which defines the maximum stress a material endures under cyclic loading without failure, fracture toughness focuses on predicting catastrophic failure from existing cracks.

Understanding Fatigue Limit: An Overview

Fatigue limit refers to the maximum stress amplitude a material can endure for an infinite number of cycles without failure, crucial in designing components subjected to repetitive loading. Fracture toughness measures a material's resistance to crack propagation, defining its ability to withstand critical crack growth under stress. Understanding fatigue limit helps engineers predict the lifespan of materials under cyclic stress, while fracture toughness informs safety margins against sudden fracture.

Material Properties Influencing Fracture Toughness

Fracture toughness measures a material's ability to resist crack propagation under stress, significantly influenced by microstructure, grain size, and alloy composition. Fatigue limit defines the maximum stress a material can endure for infinite cycles without failure, primarily affected by surface finish, residual stress, and environmental conditions. Material properties such as crack tip plasticity, phase distribution, and toughness-enhancing precipitates play critical roles in enhancing fracture toughness.

Factors Affecting Fatigue Limit in Materials

Fatigue limit in materials is influenced by factors such as surface finish, microstructure, temperature, and environmental conditions like corrosion. Grain size and alloy composition also play crucial roles in enhancing resistance to crack initiation and propagation under cyclic loading. These factors differ from fracture toughness, which primarily measures a material's resistance to crack growth under a static or monotonic load.

Comparative Analysis: Fracture Toughness vs. Fatigue Limit

Fracture toughness quantifies a material's ability to resist crack propagation under a single, sudden load, measured by critical stress intensity factor (K_IC), while fatigue limit defines the maximum cyclic stress a material can endure indefinitely without failure. Fatigue limit primarily applies to metals with a distinct endurance threshold, whereas fracture toughness is critical for predicting failure in brittle materials or structures containing flaws. Analyzing both parameters allows engineers to optimize material selection and design for structural integrity under both static and cyclic loading conditions.

Testing Methods for Fracture Toughness and Fatigue Limit

Fracture toughness testing primarily employs methods such as the single-edge notch bend (SENB) and compact tension (CT) tests, which measure a material's resistance to crack propagation under a controlled, increasing load. Fatigue limit testing uses cyclic loading techniques, including rotating bending and axial fatigue tests, to determine the stress level below which a material can endure an infinite number of loading cycles without failure. Both testing methods rely on precise instrumentation to record crack growth rates and fatigue life, ensuring accurate characterization of material durability under different stress conditions.

Practical Applications in Engineering and Design

Fracture toughness measures a material's ability to resist crack propagation under stress, crucial for preventing catastrophic failures in high-stress components like aerospace structures and pressure vessels. Fatigue limit defines the maximum stress a material can endure for infinite cycles without failure, essential for designing rotating machinery, bridges, and automotive parts subjected to repetitive loading. Engineers integrate both properties to optimize safety and durability, selecting materials and designing components that withstand both sudden impacts and long-term cyclic stresses.

Case Studies: Failure Analysis Based on Toughness and Fatigue

Case studies in failure analysis reveal that materials with high fracture toughness resist crack propagation under sudden impact, while those with elevated fatigue limits endure cyclic stresses without crack initiation. For instance, aerospace components exhibiting low fracture toughness often fail catastrophically despite fatigue limits exceeding operational stresses. Understanding the relationship between fracture toughness and fatigue limit enables engineers to predict failure modes and design materials that optimize both crack resistance and cyclic durability.

Enhancing Material Performance: Future Perspectives

Fracture toughness and fatigue limit are critical properties influencing material durability and lifespan under stress, with fracture toughness indicating a material's resistance to crack propagation and fatigue limit defining the stress level below which fatigue failure is unlikely. Enhancing material performance in future applications focuses on developing advanced composites, nano-engineered materials, and surface treatments that improve both fracture toughness and fatigue resistance simultaneously. Emerging techniques like additive manufacturing and AI-driven material design enable precise control over microstructures, promising significant advancements in the combined optimization of fracture toughness and fatigue limit.

Fracture toughness Infographic

libterm.com

libterm.com