Interrupted cutting occurs when the cutting tool encounters varying material hardness or gaps, causing uneven material removal and potential tool damage. This machining challenge reduces surface quality and tool life, impacting production efficiency. Discover effective strategies to manage interrupted cutting and enhance your machining processes in the rest of the article.

Table of Comparison

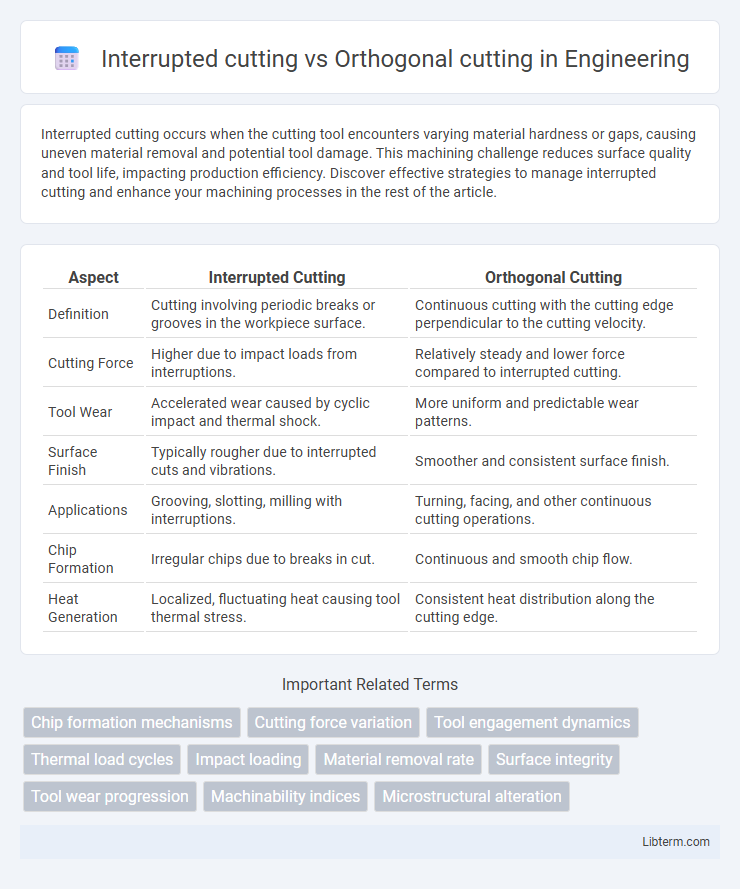

| Aspect | Interrupted Cutting | Orthogonal Cutting |

|---|---|---|

| Definition | Cutting involving periodic breaks or grooves in the workpiece surface. | Continuous cutting with the cutting edge perpendicular to the cutting velocity. |

| Cutting Force | Higher due to impact loads from interruptions. | Relatively steady and lower force compared to interrupted cutting. |

| Tool Wear | Accelerated wear caused by cyclic impact and thermal shock. | More uniform and predictable wear patterns. |

| Surface Finish | Typically rougher due to interrupted cuts and vibrations. | Smoother and consistent surface finish. |

| Applications | Grooving, slotting, milling with interruptions. | Turning, facing, and other continuous cutting operations. |

| Chip Formation | Irregular chips due to breaks in cut. | Continuous and smooth chip flow. |

| Heat Generation | Localized, fluctuating heat causing tool thermal stress. | Consistent heat distribution along the cutting edge. |

Introduction to Cutting Processes

Interrupted cutting involves periodic engagement and disengagement of the cutting tool with the workpiece, causing fluctuations in cutting forces and increased tool wear compared to orthogonal cutting, where the cutting edge moves continuously at a constant depth. Orthogonal cutting features a straight cutting edge perpendicular to the direction of tool motion, facilitating simpler force analysis and smoother surface finish. Understanding these fundamental differences is crucial for optimizing machining parameters and selecting appropriate tools in various manufacturing processes.

Defining Interrupted Cutting

Interrupted cutting involves machining processes where the cutting tool intermittently engages and disengages with the workpiece, causing repeated impact loads and thermal cycling. Orthogonal cutting, by contrast, features continuous tool-workpiece contact with the cutting edge perpendicular to the direction of tool travel, generating steady-state shear deformation. Understanding interrupted cutting is crucial for optimizing tool design and selecting appropriate machining parameters to withstand dynamic forces and prevent premature tool failure.

Understanding Orthogonal Cutting

Orthogonal cutting involves a cutting edge intersecting the workpiece at a 90-degree angle, enabling simplified analysis of forces and chip formation in metal machining. This process allows precise control over cutting parameters such as speed, feed, and depth, resulting in improved surface finish and reduced tool wear compared to interrupted cutting. Understanding orthogonal cutting is essential for optimizing machining efficiency and predicting tool life in manufacturing operations.

Key Differences Between Interrupted and Orthogonal Cutting

Interrupted cutting involves machining operations where the cutting tool engages the workpiece periodically, leading to cyclic impacts and varied cutting forces, whereas orthogonal cutting features continuous, steady-state tool-workpiece interaction with a constant cutting edge angle perpendicular to the cutting velocity. The key differences lie in the tool engagement pattern--interrupted cutting experiences repeated tool entry and exit causing shock loads, tool wear acceleration, and surface finish variations, while orthogonal cutting maintains uniform chip formation and force distribution resulting in smoother surfaces and predictable tool life. Additionally, interrupted cutting requires tool materials and geometries that can withstand impact loading and thermal cycling, contrasting with orthogonal cutting which prioritizes sharp cutting edges for efficient shear deformation and chip flow.

Tool Wear and Life in Interrupted vs Orthogonal Cutting

Interrupted cutting typically causes more severe tool wear than orthogonal cutting due to the repeated impact and thermal cycling experienced by the tool during each interruption, leading to faster tool degradation. Tool life in interrupted cutting is significantly shorter compared to orthogonal cutting because the intermittent nature of the cut induces higher mechanical and thermal stresses, accelerating chipping and fatigue in the cutting edge. In contrast, orthogonal cutting maintains more stable cutting conditions, resulting in more uniform wear patterns and longer tool life.

Surface Finish Comparison

Interrupted cutting often results in a rougher surface finish due to the periodic engagement and disengagement of the cutting tool, which causes vibrations and tool wear. Orthogonal cutting typically produces a smoother surface finish as the continuous chip formation maintains consistent cutting forces and reduces surface irregularities. Surface finish quality in interrupted cutting can be improved by optimizing cutting parameters and tool geometry to minimize impact effects.

Chip Formation Mechanisms

Interrupted cutting generates chips through cyclic engagement and disengagement of the tool, causing periodic chip breaking and thermal variations that affect chip morphology. Orthogonal cutting produces continuous chips by maintaining a constant shear plane angle, resulting in uniform deformation and smoother chip flow. The differing chip formation mechanisms influence surface finish, tool wear, and cutting forces in manufacturing processes.

Thermal Effects and Heat Generation

Interrupted cutting generates fluctuating heat due to periodic tool engagement and disengagement, causing thermal shocks that affect tool life and workpiece integrity. Orthogonal cutting produces continuous heat along the shear zone and tool-chip interface, leading to a more stable but higher average temperature. Thermal management in interrupted cutting is critical to prevent rapid tool wear, while orthogonal cutting requires steady heat dissipation strategies to maintain cutting efficiency.

Applications of Interrupted and Orthogonal Cutting

Interrupted cutting is essential for machining processes involving materials with tough structures or applications such as milling, gear cutting, and slotting where periodic tool engagement with the workpiece occurs. Orthogonal cutting is widely used in turning and shaping operations to achieve precise surface finish and dimensional accuracy in metals with consistent chip flow. Industries such as aerospace and automotive leverage interrupted cutting for complex part geometries, while orthogonal cutting dominates in producing rotationally symmetric components with predictable cutting forces.

Selecting the Optimal Cutting Process

Selecting the optimal cutting process between interrupted cutting and orthogonal cutting depends on material properties, tool wear considerations, and desired surface finish quality. Interrupted cutting suits applications with varying chip thickness and tough materials, minimizing tool damage through periodic relief phases, while orthogonal cutting offers consistent shear and smoother machining ideal for high precision and low vibration in homogeneous materials. Analyzing factors such as cutting force stability, heat generation, and tool life guide the choice to enhance productivity and maintain dimensional accuracy.

Interrupted cutting Infographic

libterm.com

libterm.com