Axial fans are essential components in many cooling and ventilation systems, designed to move air efficiently along the axis of the fan. Their high airflow capacity and low pressure generation make them ideal for applications ranging from industrial machinery to household appliances. Discover how axial fans can optimize Your airflow needs by exploring the full article.

Table of Comparison

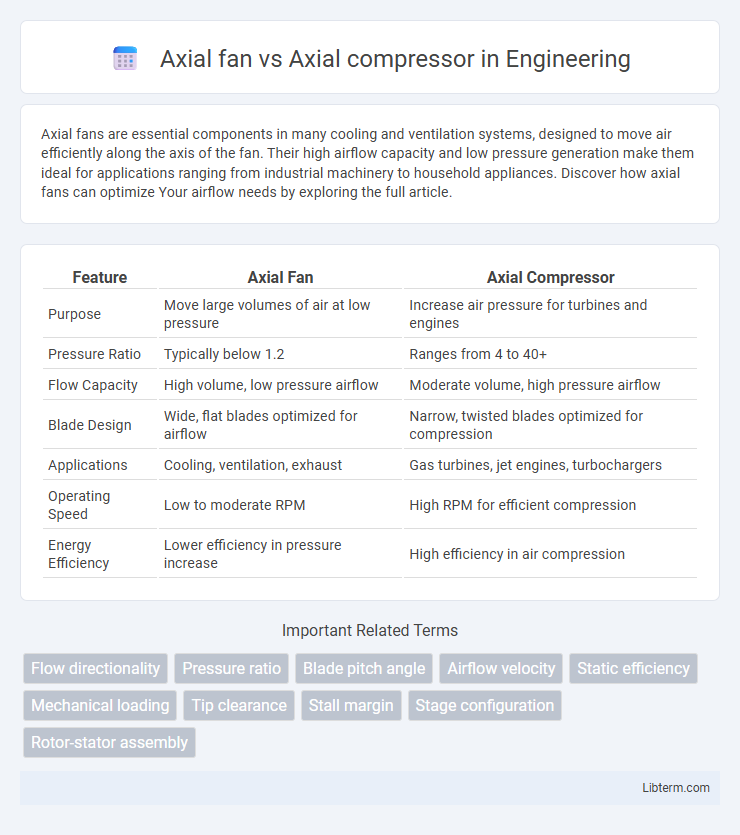

| Feature | Axial Fan | Axial Compressor |

|---|---|---|

| Purpose | Move large volumes of air at low pressure | Increase air pressure for turbines and engines |

| Pressure Ratio | Typically below 1.2 | Ranges from 4 to 40+ |

| Flow Capacity | High volume, low pressure airflow | Moderate volume, high pressure airflow |

| Blade Design | Wide, flat blades optimized for airflow | Narrow, twisted blades optimized for compression |

| Applications | Cooling, ventilation, exhaust | Gas turbines, jet engines, turbochargers |

| Operating Speed | Low to moderate RPM | High RPM for efficient compression |

| Energy Efficiency | Lower efficiency in pressure increase | High efficiency in air compression |

Introduction to Axial Fans and Axial Compressors

Axial fans and axial compressors share a similar design principle involving air moving parallel to the axis of rotation, but they serve different functions in fluid dynamics. Axial fans primarily provide air circulation and ventilation with relatively low pressure increase, making them ideal for cooling and exhaust applications. Axial compressors, on the other hand, operate at higher pressure ratios in gas turbines and jet engines, compressing air efficiently for combustion processes.

Principle of Operation: Axial Fan vs Axial Compressor

Axial fans operate by drawing air parallel to the shaft and increasing airflow through aerodynamic blade design without significant pressure rise, primarily used for ventilation and cooling. Axial compressors, however, use multiple rotating and stationary blade stages to progressively compress air, significantly increasing pressure and density for applications like jet engines and gas turbines. The principle difference lies in fans imparting kinetic energy to the air, while compressors convert kinetic energy into increased static pressure.

Key Differences in Design and Construction

Axial fans feature simpler blade designs focused on moving large volumes of air with low pressure increase, typically utilizing fewer blades with a larger chord for efficient airflow. Axial compressors have complex, aerodynamically optimized blade profiles designed to compress air by increasing pressure through multiple rotor and stator stages, resulting in higher rotational speeds and tighter clearances. Construction differences include axial fans using lightweight, corrosion-resistant materials for durability in ventilation, while axial compressors require high-strength alloys to withstand elevated stresses and temperatures in gas turbine engines.

Performance Characteristics Comparison

Axial fans and axial compressors differ significantly in performance characteristics, with axial compressors designed to achieve higher pressure ratios typically ranging from 4:1 to 12:1, while axial fans generate lower pressure increases suitable for ventilation applications. Axial compressors operate at higher rotational speeds and provide greater aerodynamic efficiency, often exceeding 85%, enabling effective air compression in jet engines and industrial processes. In contrast, axial fans prioritize high flow rates with moderate pressure rise, maintaining efficiencies around 70-80%, making them ideal for cooling and air circulation tasks.

Applications of Axial Fans

Axial fans are widely employed in HVAC systems, cooling towers, and industrial ventilation due to their ability to move large volumes of air efficiently at low pressure. Unlike axial compressors, which are designed to increase air pressure in jet engines and gas turbines, axial fans maintain airflow without significant pressure rise, making them ideal for cooling electronic equipment and exhaust ventilation. Their simple design and high airflow capacity make axial fans essential in applications requiring continuous air circulation and temperature control.

Applications of Axial Compressors

Axial compressors are primarily used in gas turbines, jet engines, and industrial processes requiring high-pressure air, such as power plants and petrochemical facilities. Their ability to handle large volumes of air at high speeds makes them essential for propulsion systems and large-scale mechanical compression tasks. Unlike axial fans, which focus on moving air for ventilation or cooling, axial compressors increase air pressure to optimize combustion and energy efficiency in various engineering applications.

Efficiency and Energy Consumption Analysis

Axial fans generally exhibit lower efficiency compared to axial compressors due to their design focus on moving large volumes of air at low pressure, resulting in higher energy consumption for equivalent airflow. Axial compressors are engineered to increase air pressure efficiently with multiple stages, achieving higher aerodynamic efficiency and reduced energy usage per unit of compressed air. Analyzing operational performance, axial compressors offer superior energy savings in industrial applications requiring pressurized airflow, while axial fans remain optimal for ventilation where pressure rise is minimal.

Maintenance Requirements and Lifespan

Axial fans typically require less maintenance due to simpler blade designs and lower operational pressures, resulting in longer intervals between service checks compared to axial compressors. Axial compressors operate under higher stress and temperature conditions, necessitating frequent inspections, blade replacements, and lubrication to prevent performance degradation and mechanical failure. The lifespan of axial fans generally exceeds that of axial compressors when operating under similar environmental conditions, primarily because compressors endure more intense operational demands.

Cost Factors and Economic Considerations

Axial fans generally incur lower initial and maintenance costs due to simpler design and materials, making them cost-effective for ventilation and cooling applications. Axial compressors, designed for higher pressure ratios and operational efficiency, involve higher manufacturing expenses and require precise engineering, increasing upfront investment and maintenance budgets. Economic considerations must weigh the total cost of ownership, where axial fans favor low-cost deployment, while axial compressors justify costs through energy savings and performance in industrial gas compression.

Choosing Between Axial Fan and Axial Compressor

Choosing between an axial fan and an axial compressor depends on the required pressure rise and application. Axial fans are designed for moving large volumes of air at low pressure, typically used in ventilation and cooling systems. Axial compressors generate higher pressure increases and are essential in gas turbines, jet engines, and industrial processes requiring compressed air.

Axial fan Infographic

libterm.com

libterm.com