Stiffness refers to the resistance of an object or material to deformation when subjected to an applied force, playing a crucial role in engineering and biomechanics. High stiffness ensures structural integrity and performance, while low stiffness allows flexibility and movement in various applications. Discover how stiffness impacts your projects and explore practical examples in the following sections.

Table of Comparison

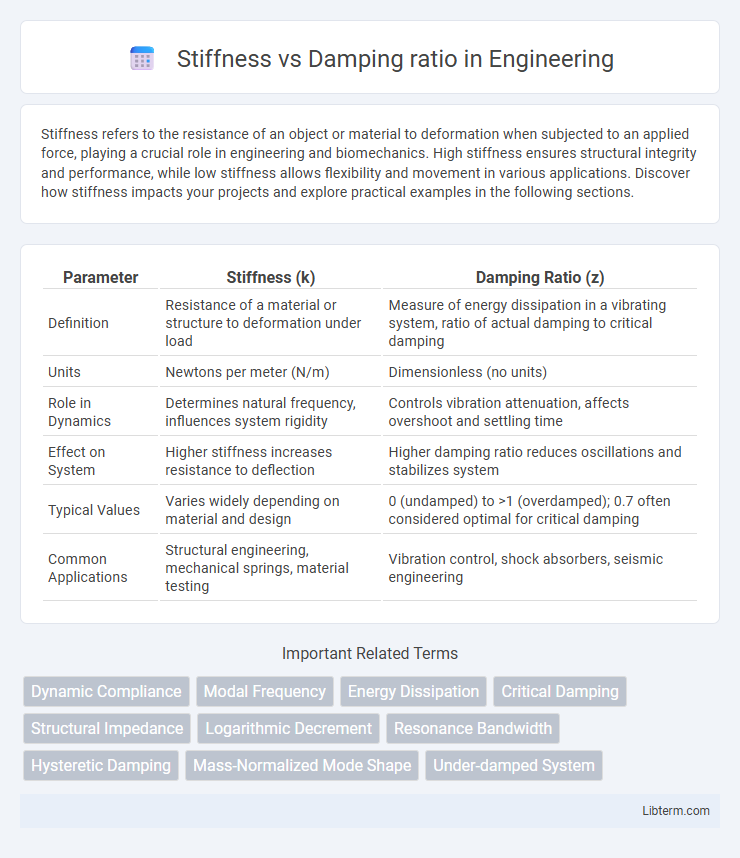

| Parameter | Stiffness (k) | Damping Ratio (z) |

|---|---|---|

| Definition | Resistance of a material or structure to deformation under load | Measure of energy dissipation in a vibrating system, ratio of actual damping to critical damping |

| Units | Newtons per meter (N/m) | Dimensionless (no units) |

| Role in Dynamics | Determines natural frequency, influences system rigidity | Controls vibration attenuation, affects overshoot and settling time |

| Effect on System | Higher stiffness increases resistance to deflection | Higher damping ratio reduces oscillations and stabilizes system |

| Typical Values | Varies widely depending on material and design | 0 (undamped) to >1 (overdamped); 0.7 often considered optimal for critical damping |

| Common Applications | Structural engineering, mechanical springs, material testing | Vibration control, shock absorbers, seismic engineering |

Understanding Stiffness: Definition and Importance

Stiffness is the property of a material or structure that defines its resistance to deformation under applied force, typically measured in units of force per unit displacement (N/m). It plays a critical role in determining the dynamic behavior of mechanical systems by influencing natural frequency and structural stability. High stiffness enhances system responsiveness and reduces excessive vibrations, making it essential for designing resilient and efficient engineering applications.

What Is Damping Ratio? Key Concepts Explained

The damping ratio is a dimensionless measure describing how oscillations in a system decay after a disturbance. It quantifies the balance between stiffness, which stores energy, and damping, which dissipates energy, influencing the speed and smoothness of system response. Key concepts include underdamping (ratio less than 1), critical damping (ratio equals 1), and overdamping (ratio greater than 1), each dictating distinct dynamic behaviors in mechanical and structural systems.

The Fundamental Differences Between Stiffness and Damping Ratio

Stiffness quantifies a material's resistance to deformation under applied force, typically measured in units of force per unit displacement (N/m), and directly affects the natural frequency of a mechanical system. The damping ratio is a dimensionless parameter representing the system's ability to dissipate energy and reduce oscillations, influencing the amplitude and decay rate of vibrations. While stiffness controls the system's elasticity and oscillation rate, the damping ratio governs how quickly those oscillations diminish over time.

How Stiffness Affects Mechanical Systems

Stiffness in mechanical systems determines the system's ability to resist deformation under applied forces, directly impacting natural frequency and vibration response. Higher stiffness increases the natural frequency, reducing displacement but potentially leading to higher acceleration and stress within components. Optimizing stiffness is crucial for balancing structural integrity and dynamic performance, especially when paired with appropriate damping ratios to control oscillations and dissipate energy efficiently.

The Role of Damping Ratio in Vibration Control

The damping ratio plays a critical role in vibration control by determining how quickly oscillations diminish in a system subject to dynamic forces. Unlike stiffness, which influences the natural frequency, damping ratio directly affects energy dissipation and vibration amplitude reduction, preventing prolonged resonance and structural fatigue. Optimizing the damping ratio enhances system stability and extends the lifespan of mechanical components by minimizing excessive vibrations.

Stiffness and Damping Ratio in Structural Engineering

Stiffness in structural engineering defines a structure's ability to resist deformation under applied loads, directly impacting its natural frequency and dynamic response. The damping ratio quantifies energy dissipation during oscillations, crucial for controlling vibrations and ensuring structural stability under dynamic loads like earthquakes or wind. Proper balance between stiffness and damping ratio optimizes performance by minimizing resonance effects and enhancing structural safety.

Mathematical Relationship: Equations and Formulas

The mathematical relationship between stiffness (k) and damping ratio (z) is defined in the context of a damped harmonic oscillator by the equation z = c / (2(mk)), where c represents the damping coefficient and m is the mass. Stiffness directly influences the natural frequency o_n = (k/m), which in turn affects the critical damping coefficient c_c = 2(mk). The damping ratio quantifies the ratio of actual damping to critical damping, correlating system stiffness and mass with energy dissipation characteristics.

Practical Applications: Stiffness vs Damping Ratio in Real Life

In mechanical systems, stiffness determines the resistance to deformation under load, crucial for maintaining structural integrity in bridges and buildings. Damping ratio influences how quickly vibrations diminish, vital in automotive suspension systems for ride comfort and stability. Optimizing the balance between stiffness and damping ratio enhances performance in aerospace engineering by minimizing oscillations and preventing structural fatigue.

Optimizing System Performance: Balancing Stiffness and Damping

Optimizing system performance requires a precise balance between stiffness and damping ratio to enhance stability and response efficiency. Higher stiffness improves natural frequency and reduces deformation, while an optimal damping ratio prevents excessive oscillations and energy loss. Achieving this balance minimizes vibration amplitude, extends component lifespan, and ensures efficient mechanical system operation.

Summary Table: Stiffness vs Damping Ratio at a Glance

The Summary Table: Stiffness vs Damping Ratio at a Glance highlights the inverse relationship between stiffness and damping ratio in mechanical systems. Higher stiffness typically results in lower damping ratios, leading to quicker oscillations but reduced energy dissipation. This table serves as a quick reference for designing systems with optimal vibration control by balancing stiffness and damping characteristics.

Stiffness Infographic

libterm.com

libterm.com