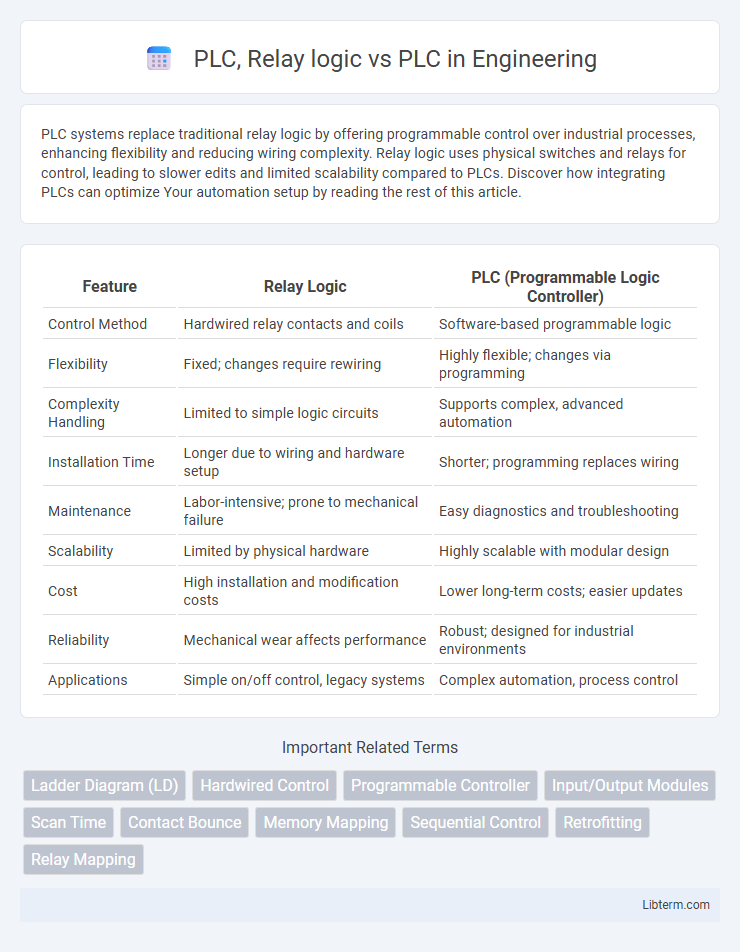

PLC systems replace traditional relay logic by offering programmable control over industrial processes, enhancing flexibility and reducing wiring complexity. Relay logic uses physical switches and relays for control, leading to slower edits and limited scalability compared to PLCs. Discover how integrating PLCs can optimize Your automation setup by reading the rest of this article.

Table of Comparison

| Feature | Relay Logic | PLC (Programmable Logic Controller) |

|---|---|---|

| Control Method | Hardwired relay contacts and coils | Software-based programmable logic |

| Flexibility | Fixed; changes require rewiring | Highly flexible; changes via programming |

| Complexity Handling | Limited to simple logic circuits | Supports complex, advanced automation |

| Installation Time | Longer due to wiring and hardware setup | Shorter; programming replaces wiring |

| Maintenance | Labor-intensive; prone to mechanical failure | Easy diagnostics and troubleshooting |

| Scalability | Limited by physical hardware | Highly scalable with modular design |

| Cost | High installation and modification costs | Lower long-term costs; easier updates |

| Reliability | Mechanical wear affects performance | Robust; designed for industrial environments |

| Applications | Simple on/off control, legacy systems | Complex automation, process control |

Introduction to Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) are specialized digital computers used for automation of industrial electromechanical processes, replacing traditional relay logic systems. Unlike relay logic that relies on physical switches and relays, PLCs offer programmable, flexible control by processing inputs through software to drive outputs, enhancing efficiency and scalability. PLCs integrate sensors, actuators, and communication systems, enabling complex control tasks with real-time monitoring and diagnostic capabilities in manufacturing and process industries.

Overview of Relay Logic Systems

Relay logic systems use electromechanical switches to control circuits through a series of interconnected relays and contacts, providing straightforward, discrete control for industrial automation. Unlike programmable logic controllers (PLCs), relay logic lacks programmability and flexibility, relying on physical rewiring to modify control sequences. These systems offer high reliability and simplicity but are limited in scalability and adaptability compared to the advanced capabilities of PLCs.

Key Components of Relay Logic Circuits

Relay logic circuits primarily consist of electromechanical relays, contacts, coils, and wiring that form a network to control electrical devices through physical switching. Key components include the relay coil, which energizes to close or open contacts, and the normally open (NO) and normally closed (NC) contacts, enabling control over the circuit paths. Unlike PLCs that use programmable software and digital inputs/outputs, relay logic relies on hardwired connections and mechanical operations for automation control.

How PLCs Work: Basic Principles

PLCs (Programmable Logic Controllers) operate by continuously scanning inputs, executing a user-programmed logic sequence, and updating outputs to control machinery efficiently. Unlike relay logic, which uses physical relays and hardwired connections to perform operations, PLCs use digital processing to execute complex control tasks quickly and flexibly. PLCs interpret ladder logic or other programming languages to simulate relay functions, enabling easy modifications and diagnostics in automated industrial processes.

Comparative Analysis: Relay Logic vs PLC

Relay logic relies on electromechanical switches for control processes, offering simplicity and robustness but limited scalability and complexity handling. Programmable Logic Controllers (PLCs) provide flexible, software-driven automation with faster response times, easier troubleshooting, and enhanced integration capabilities in industrial environments. Compared to relay logic, PLCs enable advanced programming, reduced wiring, and improved diagnostics, making them ideal for complex, large-scale control systems.

Advantages of PLCs over Relay Logic

PLCs offer significant advantages over relay logic, including enhanced flexibility through programmable software, which allows for easy modifications and scalability without physical rewiring. They provide faster processing speeds, higher reliability, and improved diagnostic capabilities, reducing downtime and maintenance costs. PLCs also support complex control algorithms, data logging, and integration with modern industrial networks, optimizing automation efficiency and precision.

Limitations of Traditional Relay Logic

Traditional relay logic systems face significant limitations including inflexibility, extensive wiring complexity, and high maintenance costs. Unlike PLCs, relay logic lacks programmability, making system modifications labor-intensive and error-prone. Limited scalability and slower processing speeds further hinder relay logic's effectiveness in modern automated control environments.

Applications: When to Use Relay Logic or PLCs

Relay logic is ideal for simple, low-cost applications where basic on/off control is sufficient, such as conveyor systems or lighting controls. PLCs excel in complex automation tasks requiring flexibility, programmability, and integration with advanced sensors and data acquisition, common in manufacturing and process industries. Choosing between relay logic and PLCs depends on factors like system complexity, scalability, and the need for remote monitoring or real-time control.

Transitioning from Relay Logic to PLC Systems

Transitioning from relay logic to PLC systems significantly improves automation efficiency by replacing complex wiring with programmable control, reducing maintenance and downtime. PLCs offer enhanced flexibility through software-based configurations, enabling quick updates and integration with modern digital networks. This shift accelerates operational processes and supports advanced diagnostics, leading to improved productivity and scalability in industrial environments.

Future Trends in Industrial Automation: The Role of PLCs

Programmable Logic Controllers (PLCs) are rapidly transforming industrial automation by replacing traditional relay logic systems with more flexible and programmable solutions. Future trends emphasize increased integration of PLCs with IoT, AI, and edge computing technologies, enabling smarter, real-time decision-making and predictive maintenance. This evolution enhances operational efficiency, reduces downtime, and supports the shift towards Industry 4.0 and digital twins in manufacturing environments.

PLC, Relay logic Infographic

libterm.com

libterm.com