Project Portfolio Management (PPM) is essential for aligning projects with organizational goals, optimizing resource allocation, and maximizing overall value. Failure Mode and Effects Analysis (FMEA) systematically identifies potential risks and failure points within processes or products, enhancing reliability and safety. Explore the rest of this article to understand how integrating PPM and FMEA can elevate your project success and risk management.

Table of Comparison

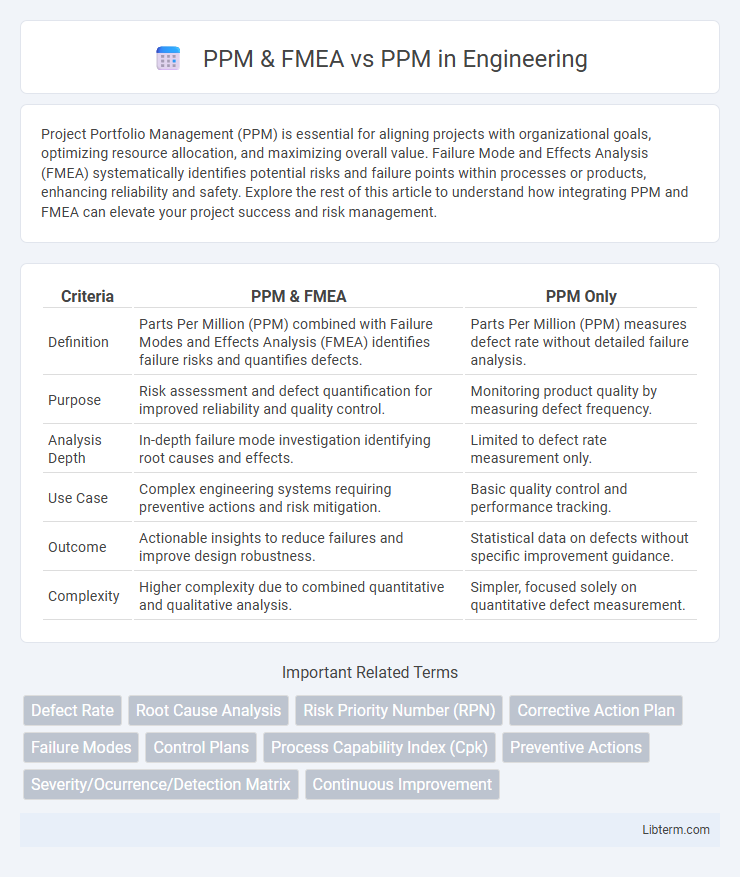

| Criteria | PPM & FMEA | PPM Only |

|---|---|---|

| Definition | Parts Per Million (PPM) combined with Failure Modes and Effects Analysis (FMEA) identifies failure risks and quantifies defects. | Parts Per Million (PPM) measures defect rate without detailed failure analysis. |

| Purpose | Risk assessment and defect quantification for improved reliability and quality control. | Monitoring product quality by measuring defect frequency. |

| Analysis Depth | In-depth failure mode investigation identifying root causes and effects. | Limited to defect rate measurement only. |

| Use Case | Complex engineering systems requiring preventive actions and risk mitigation. | Basic quality control and performance tracking. |

| Outcome | Actionable insights to reduce failures and improve design robustness. | Statistical data on defects without specific improvement guidance. |

| Complexity | Higher complexity due to combined quantitative and qualitative analysis. | Simpler, focused solely on quantitative defect measurement. |

Understanding PPM: An Overview

Understanding PPM (Parts Per Million) involves quantifying defects or errors in manufacturing or processes, serving as a crucial metric for quality control and performance assessment. FMEA (Failure Modes and Effects Analysis) complements PPM by identifying potential failure points and their impacts, enabling proactive risk mitigation before defects occur. While PPM measures the outcome in terms of defect rate, FMEA analyzes and prevents failures to improve the PPM metric effectively.

Introduction to FMEA: Key Concepts

FMEA (Failure Modes and Effects Analysis) is a systematic approach used to identify potential failure modes, their causes, and effects to enhance product reliability and safety, complementing traditional PPM (Parts Per Million) metrics. While PPM quantifies defect rates to measure manufacturing quality, FMEA proactively assesses risk by prioritizing failure modes based on severity, occurrence, and detection ratings. Implementing FMEA early in product development supports targeted risk mitigation strategies, reducing defects and lowering PPM values effectively.

PPM & FMEA: Complementary Approaches

PPM (Parts Per Million) and FMEA (Failure Modes and Effects Analysis) serve complementary roles in quality management, with PPM providing a quantitative measure of defective units in a production batch and FMEA offering a systematic evaluation of potential failure modes and their impacts. Integrating PPM metrics with FMEA activities enhances risk prioritization by focusing on defects with the highest occurrence rates and severity levels, improving corrective action effectiveness. This synergy enables proactive quality control and continuous improvement, reducing product failures and boosting customer satisfaction.

PPM vs. PPM: Clarifying the Terminology

PPM in quality management typically refers to "Parts Per Million," a metric for defect rates, while PPM can also mean "Project Portfolio Management," a strategic approach to managing multiple projects. Clarifying whether PPM denotes a quality metric or a management methodology is essential to avoid confusion in communication. FMEA (Failure Modes and Effects Analysis) complements the PPM (Parts Per Million) metric by systematically identifying potential failures to reduce defects and improve product reliability.

The Role of FMEA in Quality Management

FMEA (Failure Modes and Effects Analysis) plays a critical role in quality management by systematically identifying potential failure points within processes and products to reduce defects and improve reliability. Unlike PPM (Parts Per Million), which serves as a performance metric measuring defects, FMEA proactively prevents failures through risk assessment and mitigation strategies. Implementing FMEA enhances quality control frameworks by enabling organizations to target root causes, thereby lowering PPM rates and ensuring higher customer satisfaction.

Comparative Analysis: PPM, FMEA, and Their Integration

PPM (Parts Per Million) measures defect rates to quantify quality performance, while FMEA (Failure Modes and Effects Analysis) systematically identifies potential failure points to mitigate risks during product development. Integrating PPM data with FMEA enhances predictive maintenance by targeting high-risk components with proven defect patterns, optimizing reliability and manufacturing efficiency. This combined approach drives continuous improvement by aligning quantitative defect metrics with qualitative risk assessments, enabling proactive quality control.

Benefits of Combining PPM with FMEA

Combining PPM (Planned Preventive Maintenance) with FMEA (Failure Modes and Effects Analysis) enhances equipment reliability by proactively identifying potential failure modes and scheduling targeted maintenance activities. This integration reduces unplanned downtime, improves asset lifespan, and optimizes maintenance resources through data-driven decision-making. Leveraging FMEA insights within PPM strategies enables organizations to prioritize high-risk components and implement preventative actions precisely where they are most needed.

Limitations of PPM Without FMEA

PPM (Parts Per Million) measures defect rates but lacks the ability to identify root causes or failure modes, limiting its effectiveness in quality control. Without FMEA (Failure Modes and Effects Analysis), PPM data provides no insight into potential failures or their impacts, hindering proactive risk management. Integrating FMEA with PPM enables systematic failure identification and prioritization, improving preventive actions and reducing defect occurrence.

Best Practices for Implementing PPM & FMEA

Effective implementation of PPM and FMEA requires integrating predictive maintenance schedules with comprehensive risk assessment matrices to identify potential failures early in the process. Utilizing data-driven insights and cross-functional team collaboration enhances the accuracy of failure mode detection and optimizes maintenance intervals. Consistent documentation, real-time monitoring, and continuous improvement cycles ensure that both PPM and FMEA strategies reduce downtime and improve asset reliability.

Future Trends in Quality Management: PPM and FMEA

Future trends in quality management emphasize integrating PPM (Parts Per Million) metrics with advanced FMEA (Failure Modes and Effects Analysis) techniques to enhance predictive maintenance and risk mitigation. The synergy between real-time data analytics and AI-driven FMEA models enables more accurate identification of potential failure modes, significantly reducing PPM rates. Embracing digital transformation in quality control systems accelerates continuous improvement, ensuring product reliability and customer satisfaction in evolving manufacturing environments.

PPM & FMEA Infographic

libterm.com

libterm.com