Laser beam machining (LBM) utilizes a high-powered laser to precisely cut or engrave materials by melting or vaporizing the surface. This non-contact process excels in machining hard or delicate materials with minimal thermal distortion and high accuracy. Explore the rest of the article to understand how laser beam machining can enhance your manufacturing or fabrication projects.

Table of Comparison

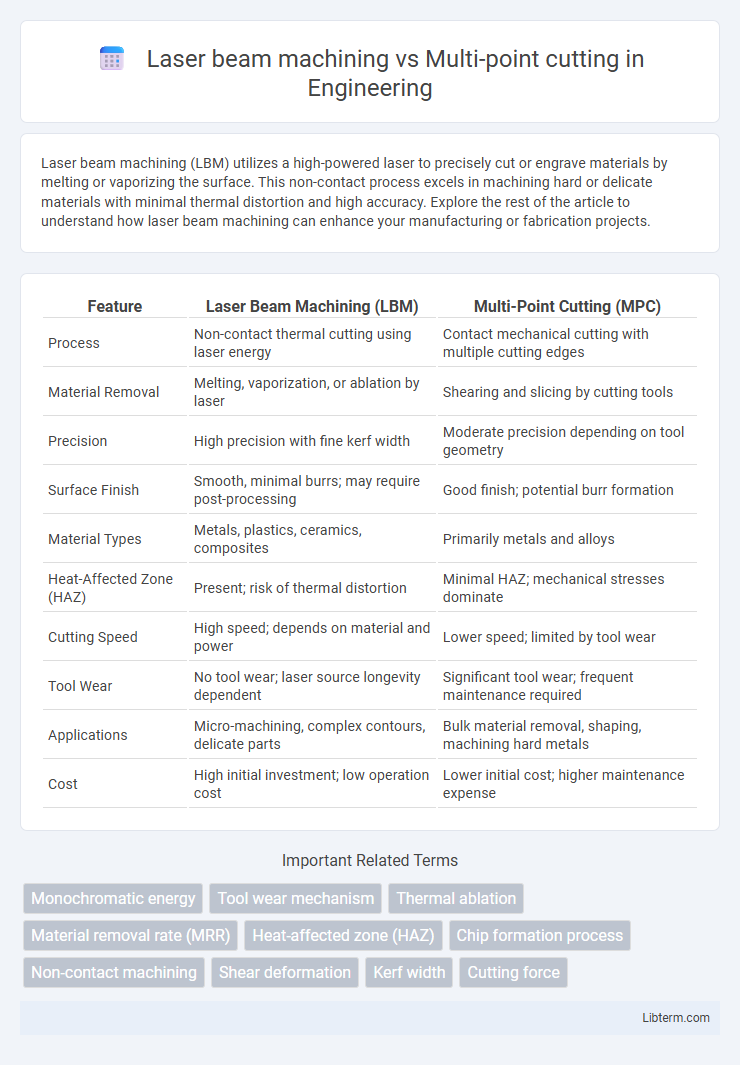

| Feature | Laser Beam Machining (LBM) | Multi-Point Cutting (MPC) |

|---|---|---|

| Process | Non-contact thermal cutting using laser energy | Contact mechanical cutting with multiple cutting edges |

| Material Removal | Melting, vaporization, or ablation by laser | Shearing and slicing by cutting tools |

| Precision | High precision with fine kerf width | Moderate precision depending on tool geometry |

| Surface Finish | Smooth, minimal burrs; may require post-processing | Good finish; potential burr formation |

| Material Types | Metals, plastics, ceramics, composites | Primarily metals and alloys |

| Heat-Affected Zone (HAZ) | Present; risk of thermal distortion | Minimal HAZ; mechanical stresses dominate |

| Cutting Speed | High speed; depends on material and power | Lower speed; limited by tool wear |

| Tool Wear | No tool wear; laser source longevity dependent | Significant tool wear; frequent maintenance required |

| Applications | Micro-machining, complex contours, delicate parts | Bulk material removal, shaping, machining hard metals |

| Cost | High initial investment; low operation cost | Lower initial cost; higher maintenance expense |

Introduction to Laser Beam Machining and Multi-Point Cutting

Laser beam machining (LBM) utilizes a high-energy laser beam to precisely remove material through melting, vaporization, or chemical ablation, offering non-contact cutting ideal for intricate designs and hard-to-machine materials. Multi-point cutting involves simultaneous engagement of multiple cutting edges, distributing the machining load to enhance productivity and surface finish in processes like milling and drilling. LBM excels in achieving micro-level precision with minimal mechanical stress, while multi-point cutting optimizes material removal rates and tool life in conventional machining applications.

Working Principles: Laser Beam Machining vs Multi-Point Cutting

Laser beam machining operates by using a concentrated laser beam to melt, vaporize, or chemically alter material surfaces with high precision and minimal mechanical stress. Multi-point cutting employs multiple cutting edges or tools simultaneously to remove material through shearing action, enhancing machining speed and efficiency on complex geometries. The fundamental difference lies in laser beam machining being a non-contact thermal process, whereas multi-point cutting is a mechanical process involving direct tool-workpiece interaction.

Material Compatibility and Selection Criteria

Laser beam machining excels in processing hard, brittle, and heat-resistant materials like ceramics, composites, and superalloys due to its non-contact, high-precision energy delivery. Multi-point cutting is suitable for ductile metals and softer materials such as aluminum, copper, and plastics, where mechanical chip removal and tool stability are critical. Material selection hinges on thermal conductivity, brittleness, and mechanical properties, with laser machining favored for materials intolerant to mechanical stresses and multi-point cutting preferred for uniform metal removal in machinable alloys.

Precision and Surface Finish Comparison

Laser beam machining offers superior precision with micron-level accuracy due to its non-contact process and highly focused energy beam, minimizing material distortion. Multi-point cutting relies on physical tool interaction, which can lead to tool wear and micro-tears that reduce surface finish quality. Consequently, laser beam machining consistently achieves finer surface finishes with reduced roughness compared to multi-point cutting methods.

Speed and Efficiency in Material Removal

Laser beam machining offers superior speed and precision in material removal, especially for intricate designs and hard materials, achieving high cutting rates with minimal tool wear. Multi-point cutting excels in bulk material removal and is efficient for large, simple geometries but typically suffers from slower speeds due to mechanical tool engagement and frequent tool changes. Laser beam machining reduces downtime and increases throughput in industries requiring rapid prototyping and fine detail, whereas multi-point cutting remains cost-effective for heavy-duty, large-scale manufacturing processes.

Tool Wear and Maintenance Requirements

Laser beam machining exhibits negligible tool wear due to its non-contact material removal process, significantly reducing maintenance needs compared to multi-point cutting methods. Multi-point cutting involves continuous physical contact between tools and workpieces, leading to accelerated tool wear and frequent tool replacements or reconditioning. Consequently, laser beam machining offers superior tool longevity and minimal maintenance costs, enhancing productivity in precision manufacturing environments.

Heat Affected Zone and Thermal Effects

Laser beam machining produces a smaller Heat Affected Zone (HAZ) compared to multi-point cutting due to its focused energy and rapid material removal, minimizing thermal distortion. Multi-point cutting generates a larger HAZ as frictional heat and mechanical forces cause significant thermal effects and microstructural changes. Controlling thermal input in laser beam machining reduces material deformation and enhances precision, making it advantageous for heat-sensitive applications.

Applications in Modern Manufacturing

Laser beam machining excels in precision micro-fabrication and intricate components for aerospace and medical device industries, offering non-contact, high-speed material removal suitable for hard and delicate materials. Multi-point cutting finds extensive use in bulk metal removal and complex geometries in automotive and heavy machinery manufacturing due to its efficiency and reduced tool wear. Both technologies complement modern manufacturing by addressing specific production requirements: laser machining for fine detail and multi-point cutting for volume and rough shaping.

Cost Analysis and Economic Considerations

Laser beam machining typically incurs higher initial equipment costs due to advanced laser technology and precision components, but offers lower operational expenses with reduced tool wear and minimal material waste. Multi-point cutting involves lower upfront investment and faster cutting speeds, yet it requires frequent tool replacement and maintenance, increasing long-term costs. Economic considerations favor laser machining for complex, high-precision applications where durability and accuracy minimize rework costs, while multi-point cutting suits high-volume, less intricate tasks prioritizing upfront affordability.

Future Trends and Technological Advancements

Laser beam machining is advancing with ultra-short pulse lasers and adaptive optics, enabling higher precision and minimal thermal damage for complex materials. Multi-point cutting technology is evolving through smart tooling integrated with IoT sensors and AI-driven process optimization, improving tool life and real-time monitoring. Future trends emphasize hybrid systems combining laser and multi-point methods to enhance efficiency, reduce cycle times, and enable additive manufacturing integrations.

Laser beam machining Infographic

libterm.com

libterm.com